FABTECH Atlanta 2018

Focus on Automation

The E-volution in sheet metal working continues to progress towards a factory that is fully controlled and managed digitally. At FABTECH 2018, SafanDarley will present the latest innovations in sheet metal working, with a focus on Automation.

SafanDarley will focus this FABTECH on automation. In addition to a range of stand-alone machines, such as Electronic and Hybrid press brakes, SafanDarley will present an automatic bending system, the R-Brake and a semi-automatic press brake, the E-Brake iTC, which has been expanded with an automatic tool changer. This tool changer automatically places tools in the machine, adding efficiency without the press brake occupying additional floor space.

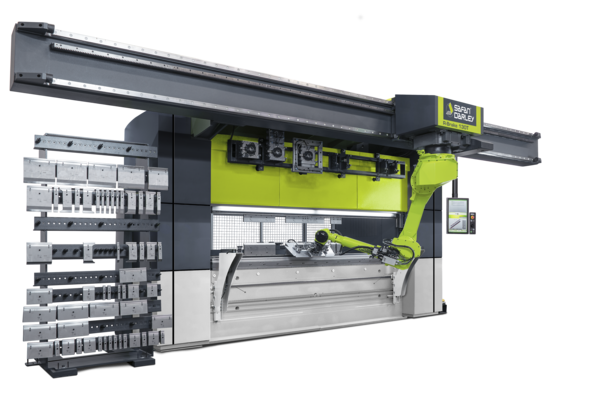

R-Brake 130T

The SafanDarley R-Brake is a revolutionary bending cell concept based on the SafanDarley E-Brake Ultra press brake. In the SafanDarley R-Brake, the press brake and robot are integrated into one system. In addition to advantages, such as completely clear floor area in front of the machine, the R-Brake can be equipped with an automated tool and gripper changing system. This also makes the R-Brake suitable for smaller batch sizes. It’s also possible to switch quick and easy to manual bending.

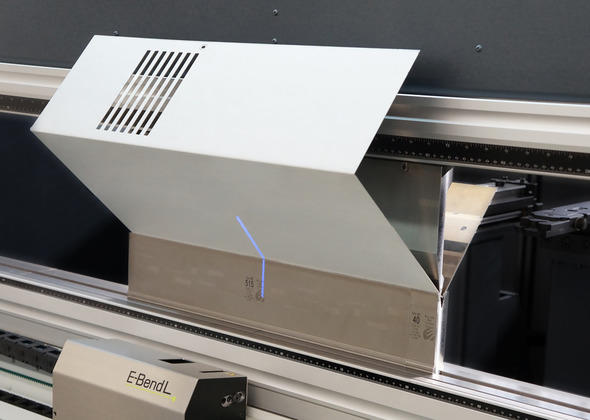

E-Brake 130T Ultra

During FABTECH, SafanDarley will also present the high-end press brake, the E-Brake 130T Ultra. The Ultra series comes standard equipped with CNC crowning as well as a dual touch screen monitor to create a paperless environment. The E-Brake 130T Ultra on the FABTECH is equipped with the optional E-Bend L Blue angle measurement system to work even more accurately and efficiently. The system constantly monitors and corrects the position of the Y axis based on the current product angle. This guarantees a final product with the highest angle precision.

H-Brake Hybrid 110T Premium

The fourth machine SafanDarley will present is the H-Brake Hybrid 110T Premium. This compact machine is specially designed to achieve higher tonnages on a short working length. The base is O-frame technology from the E-Brake range, ensuring a stable structure with minimal deflection. It is powered by energy-efficient hybrid technology, creating a compact press brake with a very high tonnage density.

On the SafanDarley booth, we will be providing AutoPOL software demonstrations. Smart bending with the innovative AutoPOL 3D-offline programming software guarantees complete and reliable process control. From 3D design to production in just a few steps.

Visit SafanDarley at booth B9029

Read more

news

The E-volution in sheet metal working continues to progress towards a factory that is fully controlled and managed digitally. At EuroBLECH 2018, SafanDarley will present the latest innovations in sheet metal working, including a complete range of automated solutions.

Folding is an essential operation that conditions the workflow in a sheet metal workshop. The challenges are numerous: productivity, precision of folded parts, safety of the operator, etc. Two main technologies are proposed by the manufacturers: machines with hydraulic drive and those with electric drive by servomotors.