R-Brake 130T

Integral and flexible

- 100% electric press brake

- Fully automated bending cell

- Save up to 50% on energy costs

- Up to 30% higher productivity

- Faster production time

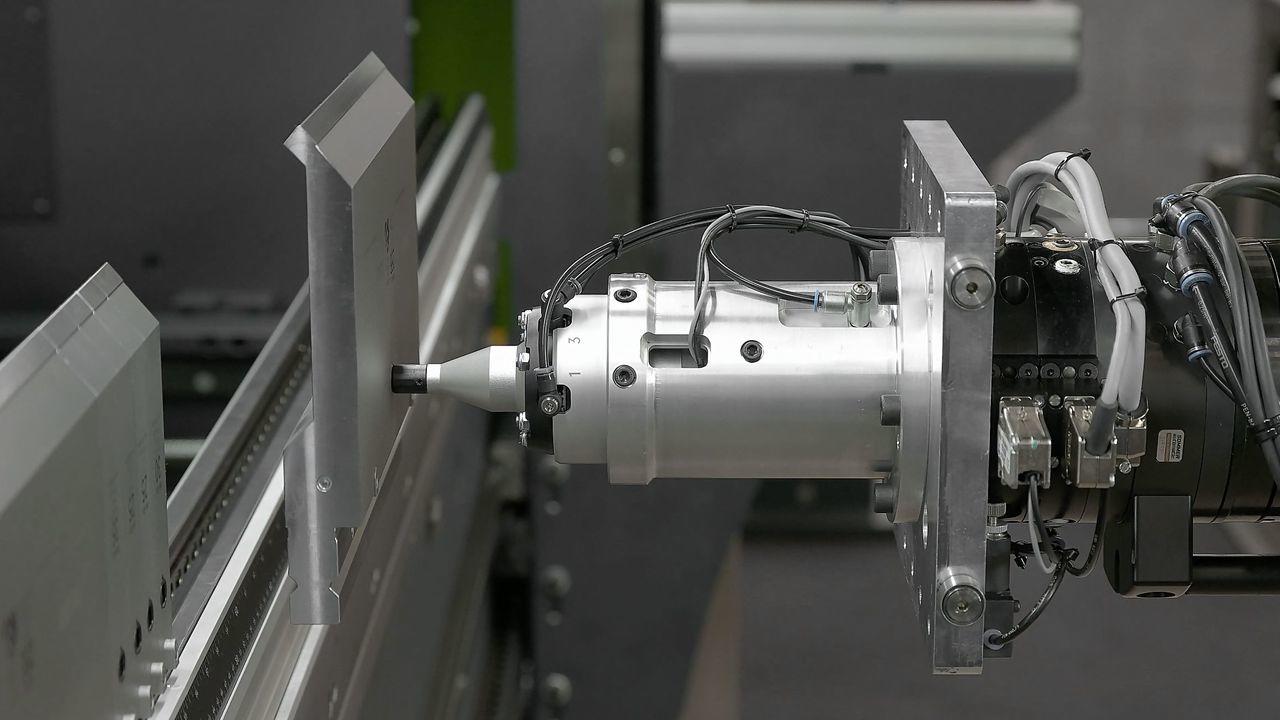

- Accurate tool change

- Lower maintenance costs

- Back gauge covers the whole working length

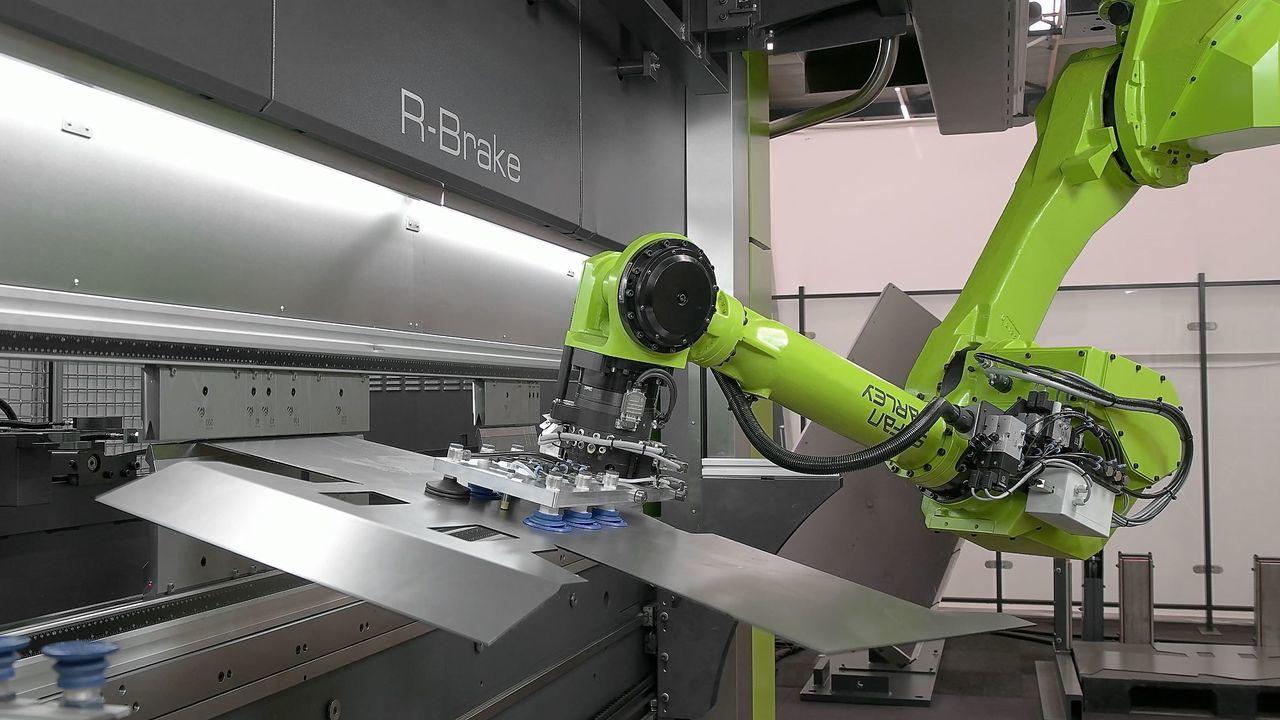

- Completely clear floor area in front of the machine

- Sub-processes can be implemented before and after bending

- operates very quietly

- Quick and easy switching to manual bending

- Easy offline programming

- Customize with standard options

- Possible to retrofit all options at any time

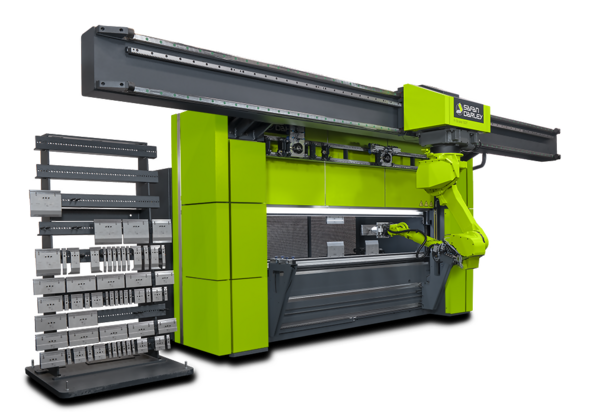

Modular construction

The SafanDarley R-Brake is available in a standard configeration, but can be expanded to a very high specification due to its modular construction and wide range of options. The modular structure enables you to select only the options you require. In this way you create the perfect machine for your production requirements. SafanDarley has extensive experience with the automation of the entire production process: from sheet delivery to the bending cell to the removal of finished products from the cell. Extending the standard 6 metre long track for the robot is also possible, as is expanding the number of tool magazines. The automated bending cell can also incorporate options such as double sheet detection and the E-Bend L angle measuring system.

SafanDarley R-Brake: the flexible bending cell

The SafanDarley R-Brake is a revolutionary bending-cell concept based on the SafanDarley E-Brake press brake. For the SafanDarley R-Brake, the press brake and the robot have been integrated into a single system. The robotic arm moves horizontally along a 6-metre long traverse at the top of the press brake. A feat of bending cell automation that ensures that the floor in front of the press brake is free for positioning sheet-feed and -discharge tables.

Request a demonstration

Thank you

Thank you for your request

SafanDarley RoboBend

With the Robobend offline software package it is possible to create a bending program and robot program simultaneously. This saves considerable time due to, among other things, automatic determination of the bending sequence and automatic merging of the bending program and the robot program. This makes it possible to determine the process at an early stage.

- Easily create programs with just a few mouse clicks.

- All information immediately visible; very user friendly.

- Open structure; offers possibilities for additional actions, such as spot welding of the product during the process.

- All steps in the bending process can be easily adjusted to your own preferences.

- Creating different stacks for the product; immediately visibility of stacks viability.

- Reversing station for extra efficiency; possibility to stack products inside each other for optimal space on the pallet.

Technical specifications

| Model | Tonnage | BowLength | Pressure force in kN | Bending length in mm | Maximum stroke in mm | Q-dimension in mm | Closing speed in mm/sec | Bending speed max. in mm/sec | Return speed in mm/sec | Motor power in kW | Weight in kg |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 130-3100 | 130 | 3100 | 1300 | 3100 | 300 | 790 | 110 | 20* | 110 | 20 | 18.500 |

- SafanDarley R-Brake 130T

- Pressure force 130 tons, cutting length 3100 mm

- Integrated robotic arm with 50 kg capacity, optionally 70 kg

- Traverse length 6 metres.

- All the advantages of SafanDarley E-Brake technology

- Comes standard with a zero table

- Simple and fast changeover to manual bending

- Optional Vision system

- Optional traverse extension to 12 metres

- Optional double-sheet detection

- Optional pre-positioner for sheet feed

- Optional off-line programming with SafanDarley RoboBend simulation software

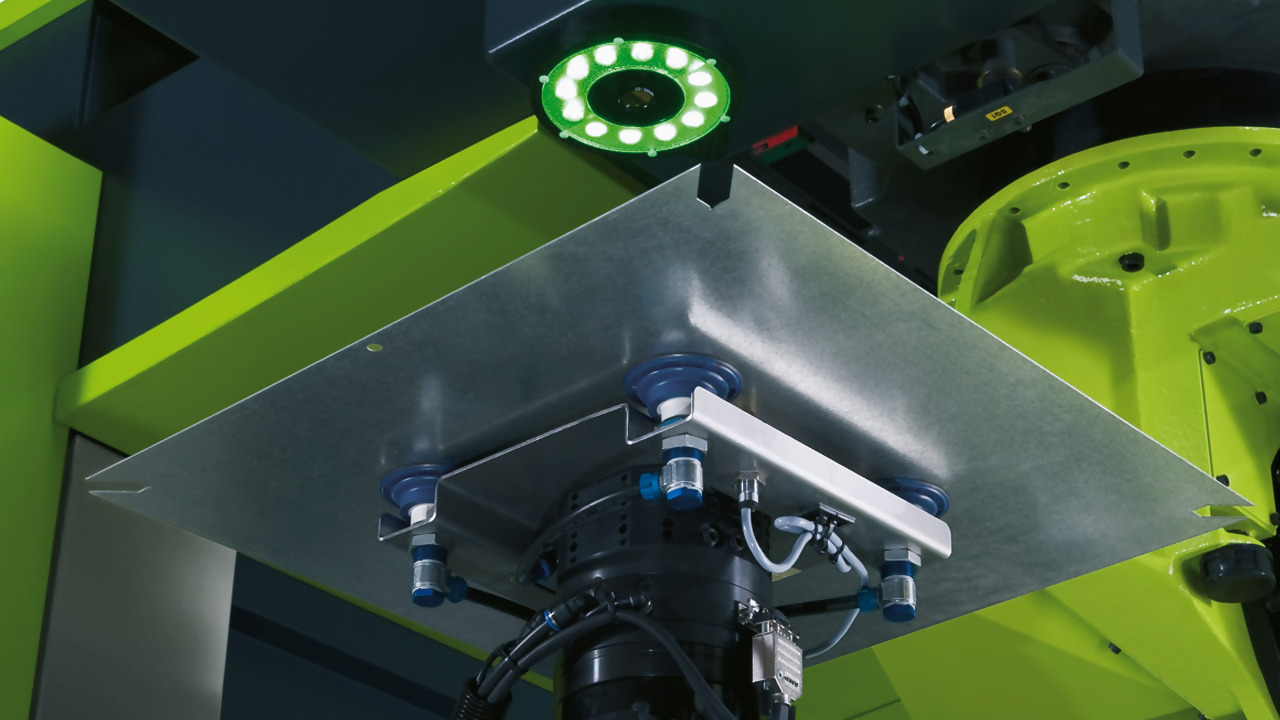

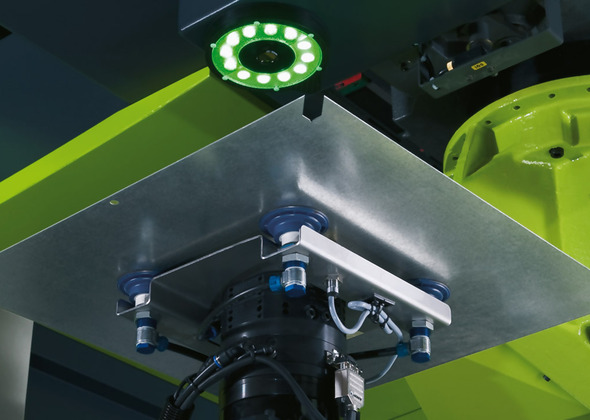

Vision system

The machine is standard equipped with a positioning table but optionally the basic model can be equipped with a vision system for defining the zero position of the sheet. Double sheet detection is safeguarded by an optional sheet weight sensor which will be mounted in the gripper.