Discover a world of innovations

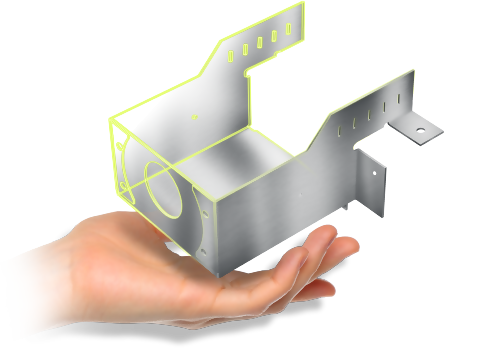

Evolution in sheet metal working

SafanDarley is the leading global specialist in developing and constructing press brakes and shears for both thin and thick sheet metal.

SafanDarley is a leading company that covers all disciplines. From R&D and engineering to manufacture and assembly. From marketing & sales to technology and training. And from helpdesk to service department. SafanDarley has 2 production plants, a head office in Lochem and a branch in Eijsden. The company employs approximately 200 members of staff.

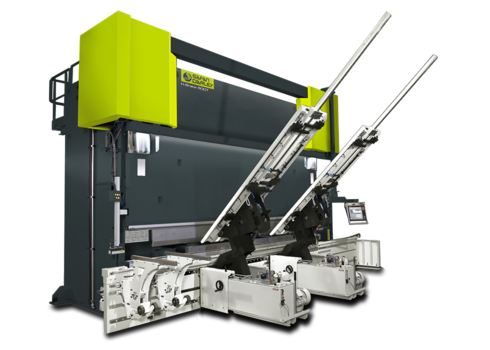

Off-line 3D-progamming

Smart Bending with the innovative Autopol 3D offline programming guarantees full and reliable process control. Thanks to the intuitive design and control, the system requires just two days training. Time that will definitely pay off with quick and flawless production.

The system operates in three simple steps.

All the news directly in your inbox

Four times a year we send a collection of interesting news to all our newsletter subscribers. Enter your e-mail address and stay informed!

Thank you

Thank you for your application

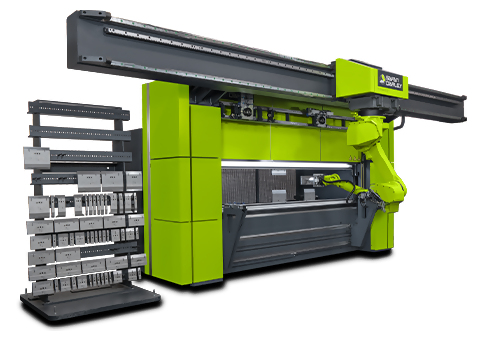

Smartmanufacturing in the Smart Industry

OEE, or Overall Equipment Effectiveness.… A new concept, but already familiar to SafanDarley. We always think along with you to integrate our machines into your manufacturing process as best as possible. Optimisation of your processes and zero defects: that is the aim for which we deploy our knowledge and innovations for you. With SafanDarley, an improvement of the OEE in your manufacturing process is feasible, without a doubt. 30% increased efficiency and more output...

Would you like to know how?

E-Bend L Blue angle measurement system

The E-Bend L Blue uses two blue laser sensors one each side of the table. The sensors are fully CNC controlled and extremely precise. The system constantly monitors and corrects the position of the Y axis based on the actual product angle. This guarantees a final product with the highest angle precision. If necessary, the system automatically adjusts the crowning axis, Y1-Y2 axis and also compensates for the spring-back.