探索一个创新的世界

了解更多 >

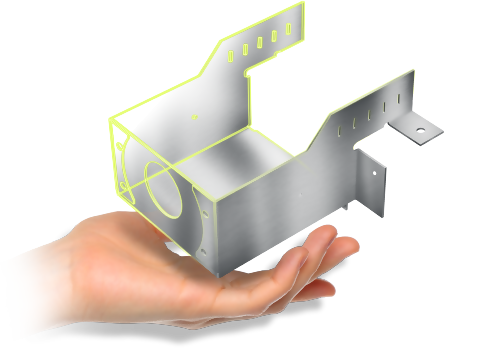

钣金加工革命

SafanDarley 是全球厚、薄钣折弯和剪裁开发的领导者

SafanDarley 是严守规律的领导公司。由开发部,到工程部、生产至最后组装;市场推广、锁售和技术支援;甚至询问到服务。SafanDarley 有两个生产基地,总部设在 Lochem,分公司设在Eijsden。全公司约有 160 位员工。

所有新資訊, 將直接寄送給您!

我們一年四次向訂閱者發送有趣的新知。 請輸入您的電子郵件地址,可隨時了解情況!

Thank you

Thank you for your application

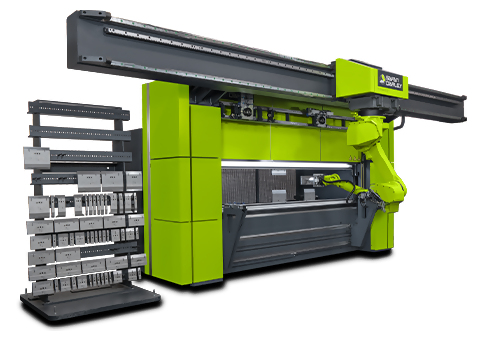

智能工业的智能生产

OEE (全面生产设备效益 简称).. 新的概念但 SafanDarley 已然熟悉。我们一直希望配合你的想法,把我们机床合成到现有生产流程,优化生产流程和零偏离;这是我们分享技术与创新的宗旨,在生产中改善 OEE,旨望提升生产效益与产能高於 30%

想知道更多?

發現更多

Automated bending as a driver for continuity and scalability

With more than 100 years of experience and a clear vision for the future, Meijer Metal deliberately invests in advanced automation. For SafanDarley, Meijer Metal is a strong example of how modern manufacturing companies structurally prepare their production for long-term continuity.

更多資料

Client boosts UK production

SafanDarley’s UK customer faced a major problem. Their existing press brakes struggled with certain parts and new product lines. This caused downtime, production delays and higher costs. A new solution was needed to increase capacity, flexibility and precision.

更多資料

The SafanDarley Autumn Edition ‘25

Built with the same advanced technology and premium quality you expect from SafanDarley, this exclusive series offers enhanced productivity, exceptional precision, and unmatched adaptability — all in one cost-efficient package.

更多資料

Video: Fully Automated Production Line at Staco

At Staco in Reuver, recently, a fully automated production line was implemented, with our SafanDarley R-Brake playing a central role. Curious to see how this tailor-made automation solution performs in practice? Watch the customer case video at Staco now.

更多資料

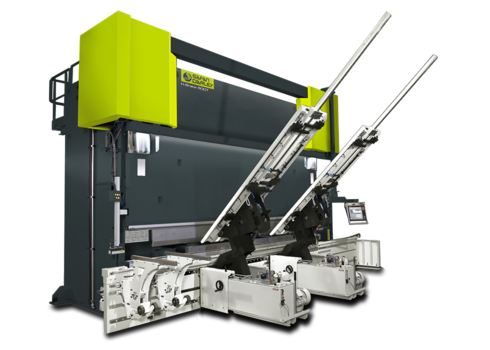

Innovation at Stetec: The E-Brake 35T Mini Cell in Action!

At Stetec in Maarheeze, innovation is key. Recently, they invested in the E-Brake 35T Mini Cell with E-Bend Check, taking a major step in their production automation. We at SafanDarley visited them to capture this in a video.

更多資料