FromE-volution to digital revolution

FromE-volution to digital revolution

The E-volution in sheet metal working continues to progress towards a factory that is fully controlled and managed digitally. At EuroBLECH 2018, SafanDarley will present the latest innovations in sheet metal working, including a complete range of automated solutions. At our stand, the press brakes will be connected to a workstation. All relevant information will be available in a single overview on a dashboard. The press brake of the future and the latest developments in programming software will also be showcased at EuroBLECH.

Back to the overview

Automatedbending solutions

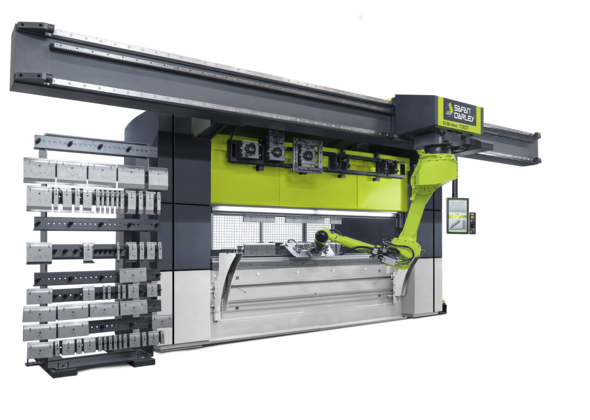

SafanDarley will exhibit the new R-Brake 130T. With the R-Brake, the press brake and the robot are integrated into one system. One of the advantages of the new R-Brake is a fully automated tool and gripper change that is connected to the machine. Together with the product, they can be programmed completely offline using SafanDarley’s RoboBend offline

simulation software.

The second automation solution on offer is the E-Brake 35T Mini Cell. This system is characterised by its compactness, making it ideal for bending smaller sized parts. The optional automatic tool and gripper change function makes it possible to quickly switch between different products.

In addition to the two fully automated solutions, SafanDarley also offers a semi-automatic E-Brake, the E-Brake iTC. This E-Brake is equipped with an automatic tool changer and offers a flexible solution for small batch production. The tool changer is built into the existing machine frame, resulting in a machine that takes up no more space than the standard E-Brake.

Back to the overview

H-Brake Hybrid 110T Premium

During EuroBLECH, SafanDarley will showcase a new model of Hybrid press brake. This unique hybrid machine has been specially developed to achieve higher tonnages on a short working length. The machine is equipped with an O-frame, which guarantees an extremely stable construction. This compact and fast machine is extremely suitable for bending small, complex parts in thicker material.

Another highlight is the press brake of the future! SafanDarley presents a new generation E-Brake concept with a unique new control drive. The well-known servo-electronic drive – which is based on SafanDarley’s own dual drive pulley principle – has been further developed, leading to a completely new machine concept. The new generation E-Brake is equipped with a C-frame, while the back gauge can be used over the entire working length. The machine also has a completely flat front, which ensures maximum bending freedom.

Back to the overviewRevisedproduct lines

SafanDarley's wide range of press brakes is grouped into two product lines. The revised range consists of the “Premium” base line and the high-end “Ultra” line.

The machines in the Premium line are characterised as being a basic version, but at a great price. The Premium versions are equipped with all the accessories necessary for a modern press brake.

On the machines in the high-end Ultra line, additional functionality has been added to the standard version compared with the Premium line. The Ultra line machines are equipped as standard with a CNC-controlled crowning table, which automatically compensates for different load situations. It is also possible to equip machines in the Ultra line with a 3D back gauge. This makes it possible to achieve the perfect back gauge positions, even for the most complex products. For even greater accuracy, the Ultra line can be equipped with the E-Bend L Blue angle measuring system.

The above product lines and the corresponding options provide a solution for working as efficiently as possible, at the lowest possible cost.

Connected Factory

Visit SafanDarley at the EuroBLECH in Hanover from 23 to 26 October 2018 in Hall 14, Stand H14 and discover the 'connected factory'.

Read more

news

Folding is an essential operation that conditions the workflow in a sheet metal workshop. The challenges are numerous: productivity, precision of folded parts, safety of the operator, etc. Two main technologies are proposed by the manufacturers: machines with hydraulic drive and those with electric drive by servomotors.

SafanDarley is adding a new model to its Hybrid brake press range with a working length of 2,050 mm. This model is available with a pressing force of 110 tons or 170 tons. The machine is compact and fast and extremely suitable for bending small, complex, thick sheet metal parts.