Discover the

World of

press brake

innovations

As the inventor of the servo-electronic press brake, SafanDarley brought about a veritable e-volution in sheet metal working.

Not only because of superior electronic technology compared to traditional hydraulics, but also through innovative machine concepts, unique control systems and optimal production automation.

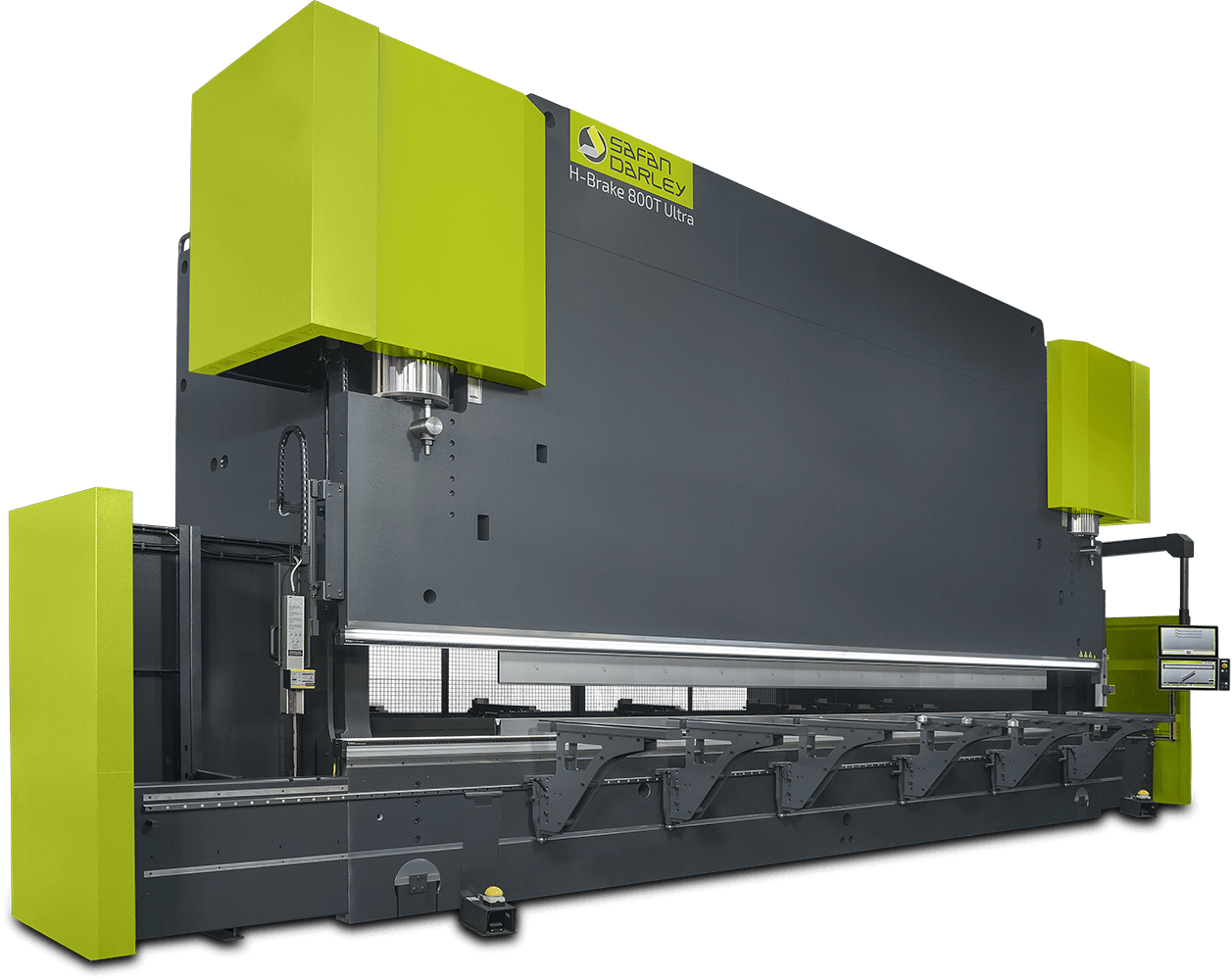

Electric press brakes from 35T to 300T

The new SafanDarley E-Brake is further optimised to take maximum advantage of the high acceleration and other favourable servo-motor characteristics.

For this reason, our E-Brake is not only very fast in the rapid approach stage, but also throughout the entire cycle.

SafanDarley is now offering integral solutions for your production process go much further than stand-alone solutions.

The integral automation is not restricted to the bending cell alone, this also applies to other parts of the process such as punching and spot-welding, and the entire routing of sheet material around the bending cell.

Transforming production experience

We use a holistic approach, offering innovative, safe, efficient and flexible machines and systems tailored to the needs of your production.

Ask us for help and allow us to review your forming process and parts to see how our technology and automation could solve many of your issues.

Research & Development in sheet metal working and handling

Continuous innovation is SafanDarley's core activity. We’re developing entirely new machines and systems, and perfecting existing machines and accessories.

Contact

SafanDarley North America LLC

N7 W23750 Bluemound Road Suite 200

Waukesha, WI 53188

USA