Fully automatic cutting centre

Fully automatic cutting centre

SafanDarley is the market leader in high quality hydraulic and hybrid guillotine shears and offers a variety of smart solutions for cutting sheet metal. The fully automatic cutting centre is one of these innovations that contributes to productivity and customer-specific efficiency.

- Special version of the hydraulic guillotine shear

- Automatic sheet feed system

- Product discharge system.

- Energy-efficient hybrid drive with lower CO2 emissions

- User-friendly Touch screen operation

- Only 22 litres of oil

- Less noise pollution

- Integrated safety system

Wide range of applications

The cutting centre can be used for various applications and is ideal for:

- Where high demands are made on repeat accuracy.

- Cutting pre-punched sheets into components.

- The clean and square cutting of single pieces from large sheets.

- Precise cutting of single pieces with the option to return the cut sheet at to the front of the machine using the return to sender system.

- Easy handling and support of very thin sheet material during the cutting process.

Material

The cutting centre is ideal for cutting

- Cold and hot rolled steel (max 6mm)

- Stainless steel (max 4mm)

- Aluminum (max 6mm)

Automatic sheet feed

The automatic sheet feed system consists of a centrally placed CNC pre-stop unit with a flat table with roller balls and equipped with 6 hydraulic clamps

Automatic sheet feed:

| Max. plate size | 3050 x 1525 x 6mm |

| Min. Plate thickness | 0,5mm |

| Min. Plate width (clamping distance) | 300mm |

| Clamp width | 60mm |

| Number of terminals | 6 |

| Max. Adjustment range CNC stop | 3500mm |

| Min. residual strip | 46mm |

| Positioning speed of CNC stop | 400mm/sec |

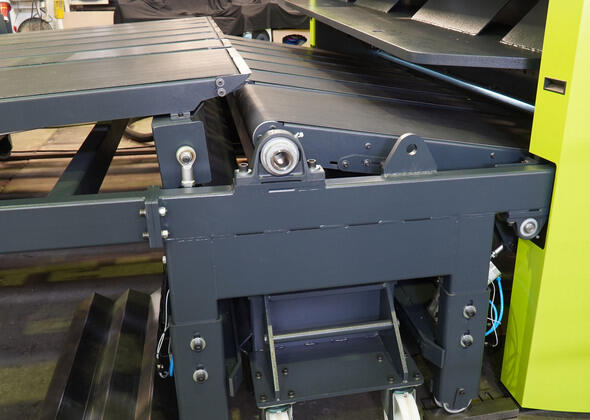

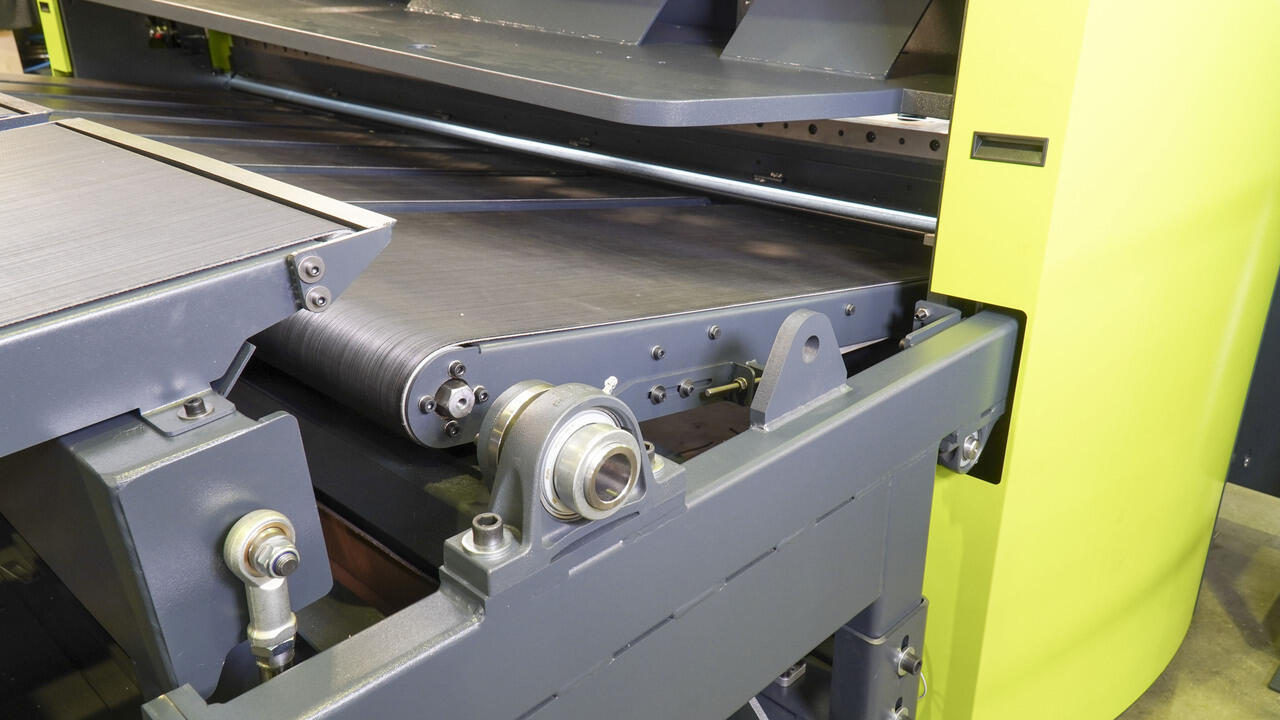

Product discharge system

The automatic product discharge system comprises of 2 conveyor belts placed one behind the other. The first conveyor belt has a hold-up function and a return device (Return to Sender).

The second transport can be lifted and then serves as a scrap flap through which the residual strips fall into a scrap bin. After cutting, the sheet is discharged or transported for the next operation, fully automatically, for optimum productivity.

Request a demonstration

Thank you

Thank you for your request

Working safety

With the fully automatic cutting centre you can work at lightning speed without risk. SafanDarley makes this possible by means of a fencing/light screen combination that shields the cutting centre. With this built-in safety feature, the built-in hydraulic clamps will retain the plate if the light beam is interrupted whilst the machine is in operation.

The E-standard of the future

-

EfficencySolutions for faster production

EfficencySolutions for faster production -

EcologyMaximum CO2 and oil reduction

EcologyMaximum CO2 and oil reduction -

ErgonomicsComplete control with one touch

ErgonomicsComplete control with one touch -

EconomyTotal flexibility with Zero Defect

EconomyTotal flexibility with Zero Defect