Multi Cell

Smart innovations, Compact Space

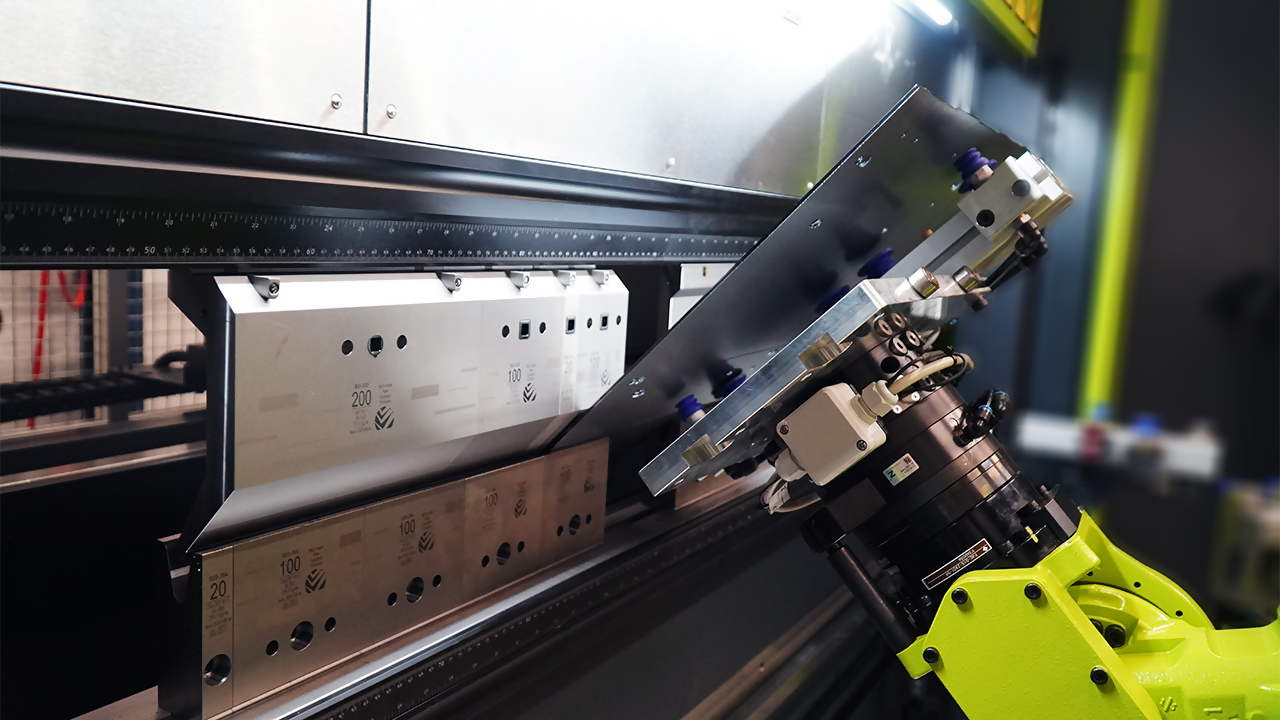

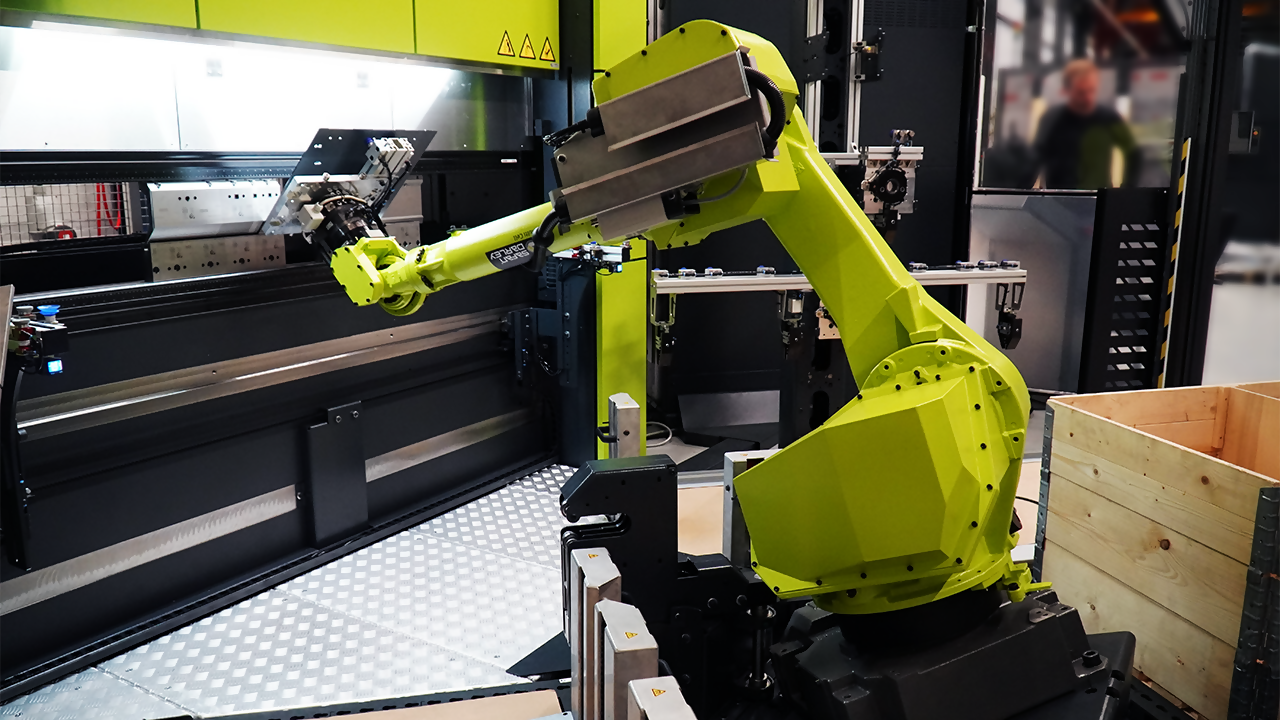

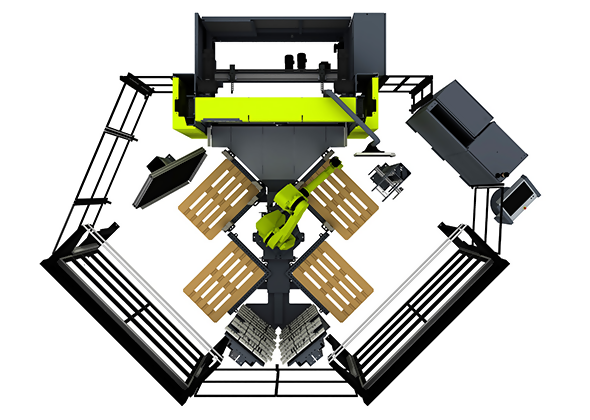

The SafanDarley Multi Cell is a versatile addition to the automated bending solutions for all midsized products up til 500x2000 mm product size and 40 to 125 Ton pressing force. This innovative automation solution allows for the bending of a wide variety of products in a very compact space.

When the market starts demanding more flexible robotized bending solutions, there is need for a change of perspective. SafanDarley has developed the ultimate solution for the mid-sized sheet metal product range by making a cell that fits every demand. This retrofit-capable system ensures that your Multi Cell stays cutting-edge, with the ability to install new technology and features as they become available, safeguarding your investment for the long term.

SafanDarley Multi Cell

- Various machines possible

- Fully modular

- Future-proof investment

- User-friendly interface

- Fast setup and minimal downtime

- Ultra-compact design

Tailored to your needs

The Multi Cell’s modular design ensures complete flexibility and customization for any production setup.

- Compatible with servo-electronic or hydraulic press brakes of 40 to 125 Ton

- Working lengths up to 2550mm

- Equipped with a 70kg Fanuc robot for ultimate flexibility

- Fully customizable software and electronics

- All options are possible to retrofit

- Modular safety fencing with manual or automatic doors

- Integration for automated feed-in/out with AGV support

The Fanuc robot is positioned centrally in front of the machine and under an angle that provides extra reach in front on the press brake to maximize flexibility.

Request a demonstration

Thank you

Thank you for your request

Software

The integrated ASC-Control and RoboBend package provides a single point of contact for complete automation needs, eliminating dependency on third parties. ASC-Control enhances user experience by enabling less experienced operators to effectively manage automated machines, ensures efficiency by automatically programming and adjusting tools and grippers for different jobs, and sets a new standard for minimizing changeover times in robotic bending processes.

The software is always in control of the complete installation which is equipped with SafanDarley’s universal Automated Solutions Electrical cabinet that provides all flexibility for the future.

The left and right side of the cell are meant for feed-in and feed-out. The software makes it possible to change the functionality of the feed-in into a feed-out pallet during the process when the pallet is empty. This ensures that there is an extra pallet for stacking parts without reserving the extra space.

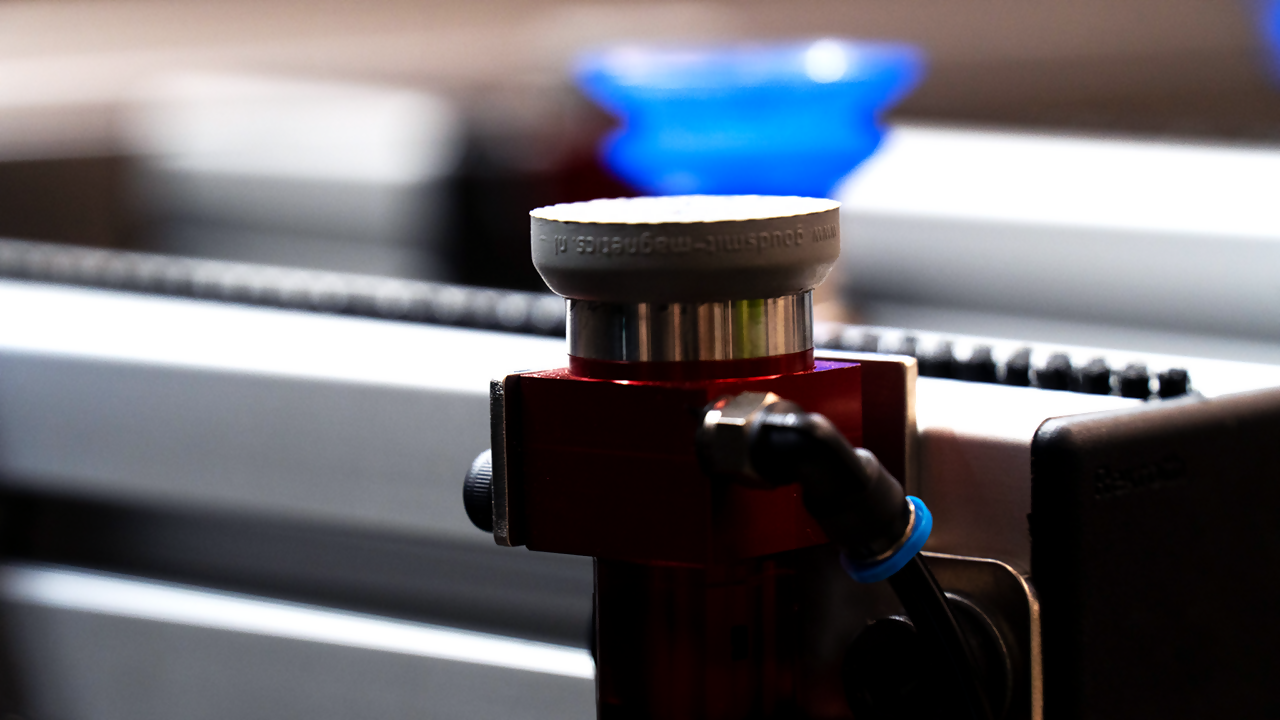

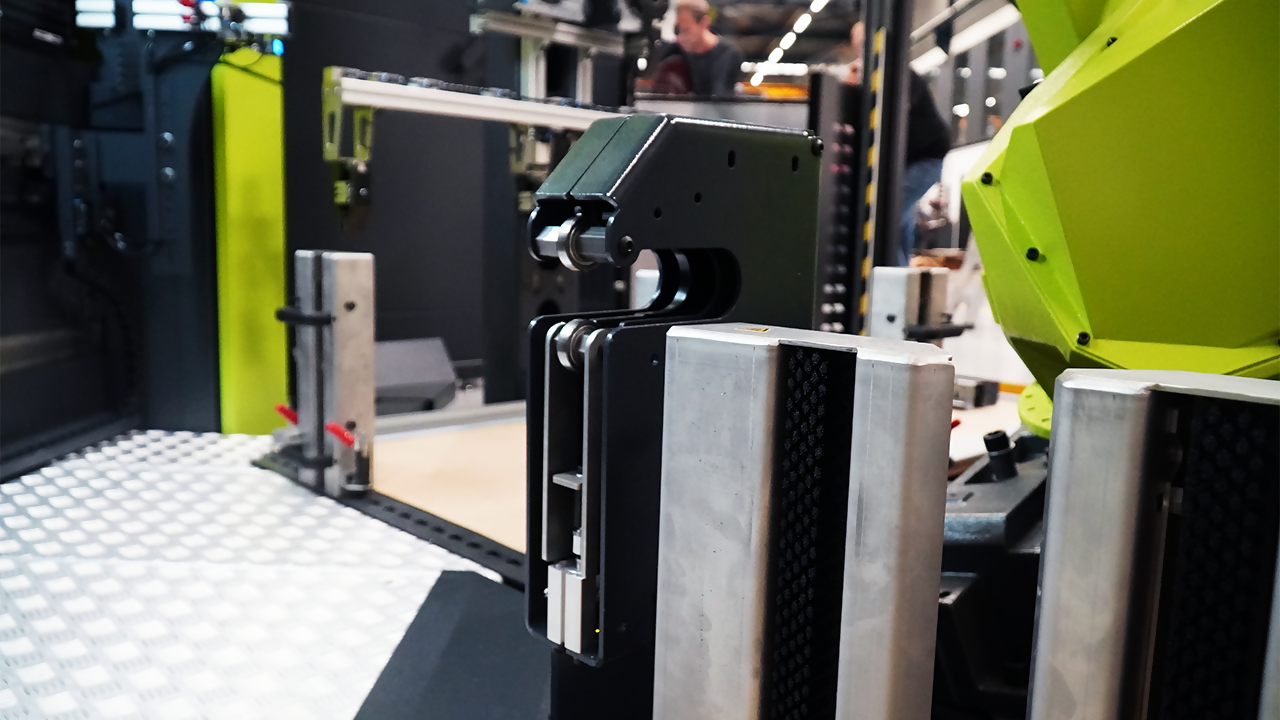

Sheet thickness

measuring system

The CNC-controlled sheet thickness measuring system accurately measures sheet thickness and at the same time performs a double sheet detection. With the thickness data immediately adjusted in the controller.

Because the Multi Cell can be equipped with 2 feed in stations, the thickness control system will automatically rotate to the correct station. This ensures that the detection is always done directly above the stack.

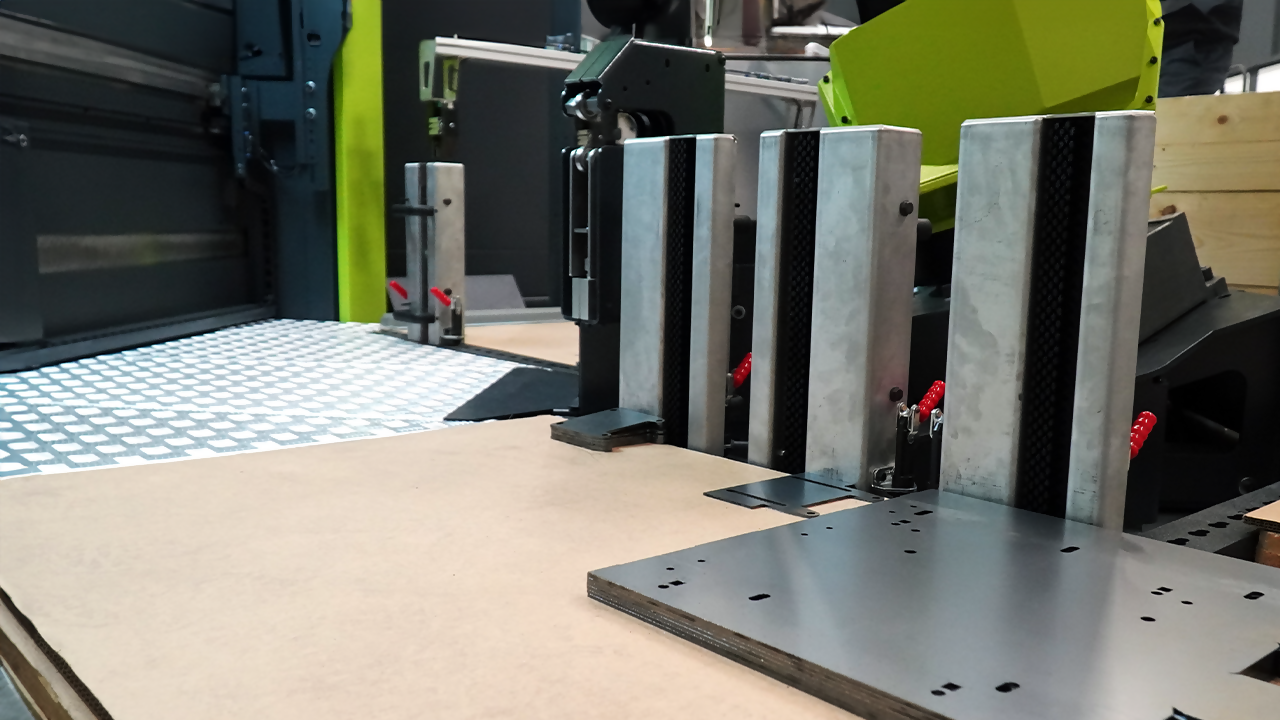

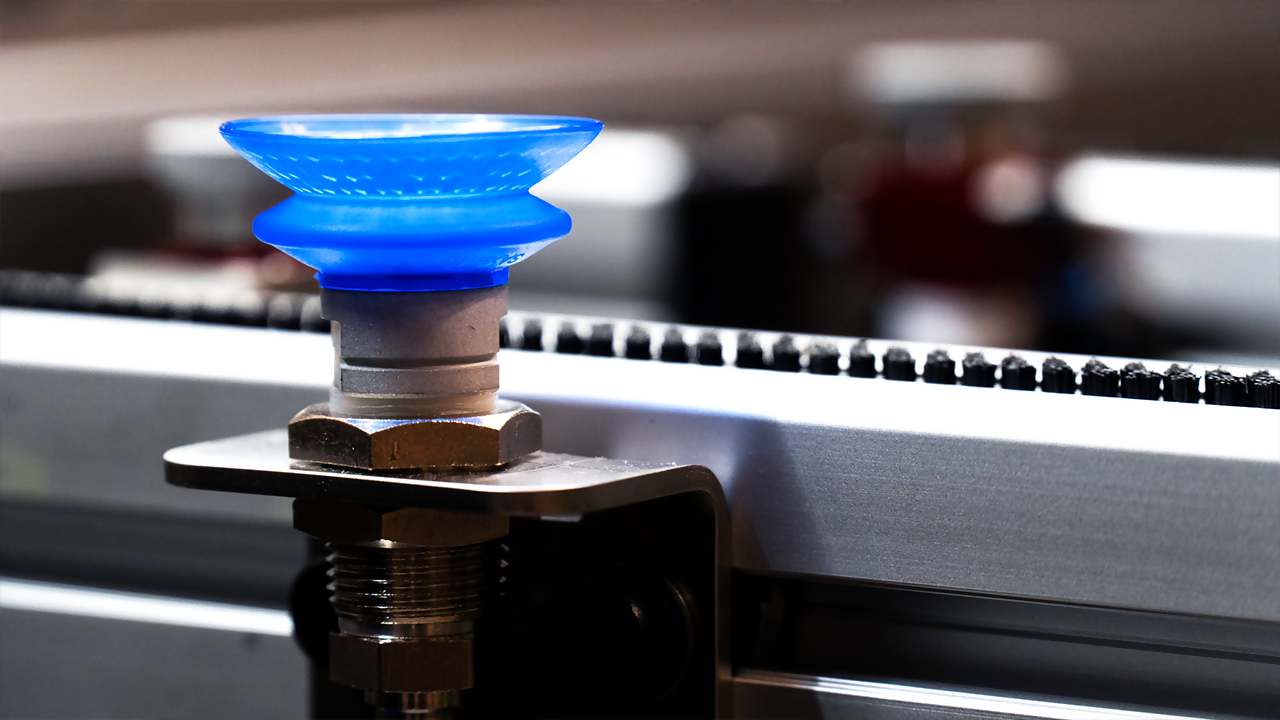

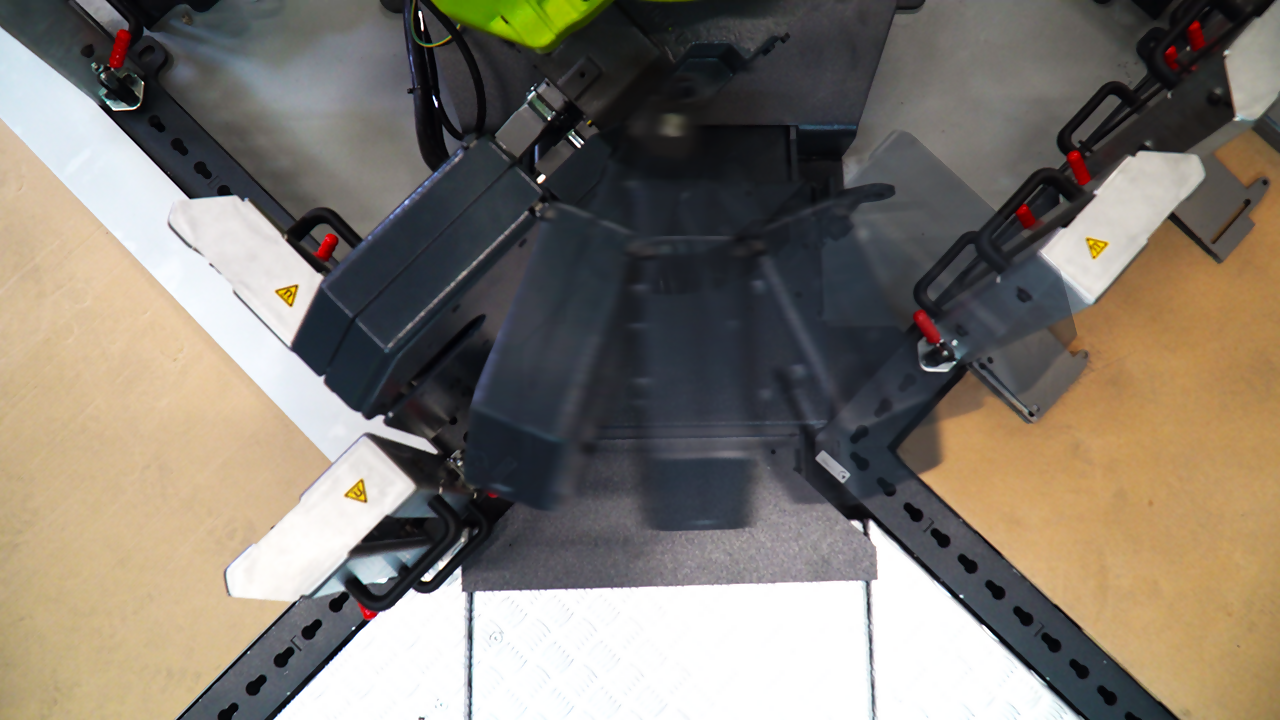

Re-take stations

The CNC-controlled support arms can be equipped with magnets, vacuum cups or clamps that transforms them into a flexible reversing station.

Because the arms are free to program in front of the press brake with an accuracy of 1 mm the system fits all different products sizes. The Re-take of the product will always take place directly in front of the machine so the movements stay within a short distance that will reduce the total cycle time.

Technical specifications

- Handling capacity of the robot: 70 kg

- Max. sheet weight for the robot: 50 kg

- Min. sheet dimension: 200 x 200mm

- Max. sheet dimension: *500 x 2000mm

- Max. sheet thickness: 8mm

- Max. stack height feed-in station: 400mm

- Max. stack height pallet: 800mm

- Maximum pallet dimension: 1000 x 2000mm

- Press brake types: E-Brake 40T-1600, E-Brake 50T-2050, E-Brake 80T-2550, H-iBrake 125T-1600 or H-iBrake 125T-2050

- Total electrical connected load: 11kW

- Air connection; G ¼” (minimal): 6 bar

- Main supply voltage: 3x400V/50-60Hz.N/Pe

- length x depth: 5.800 x 6.200mm

- Loading height for transport: 2.650mm

- Flat foundation - The floor must be flat

*Depending on sheet thickness and the press brake type.