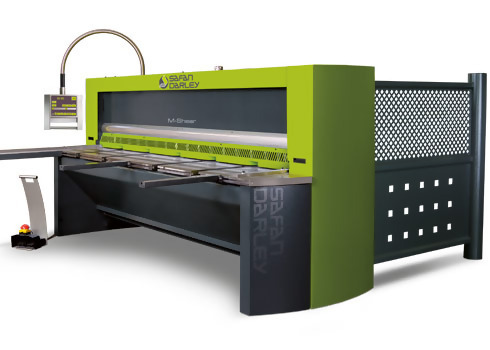

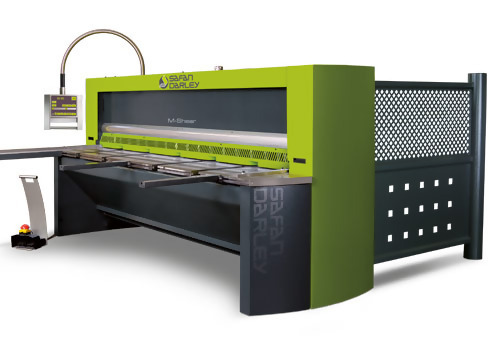

M-Shear

Superiorintegration of hydraulics and electronics

- Energy saving hybrid drive, low Co2 emissions

- Only 22 litre oil tank

- Low noise

- User friendly touch screen control

- Return-to-Sender sheet support

- Torsion free cutting of small strips

- Scrap separation

- Fully automatic adjustment of cutting angle and clearance

With the M-Shear, the blade cuts four ways

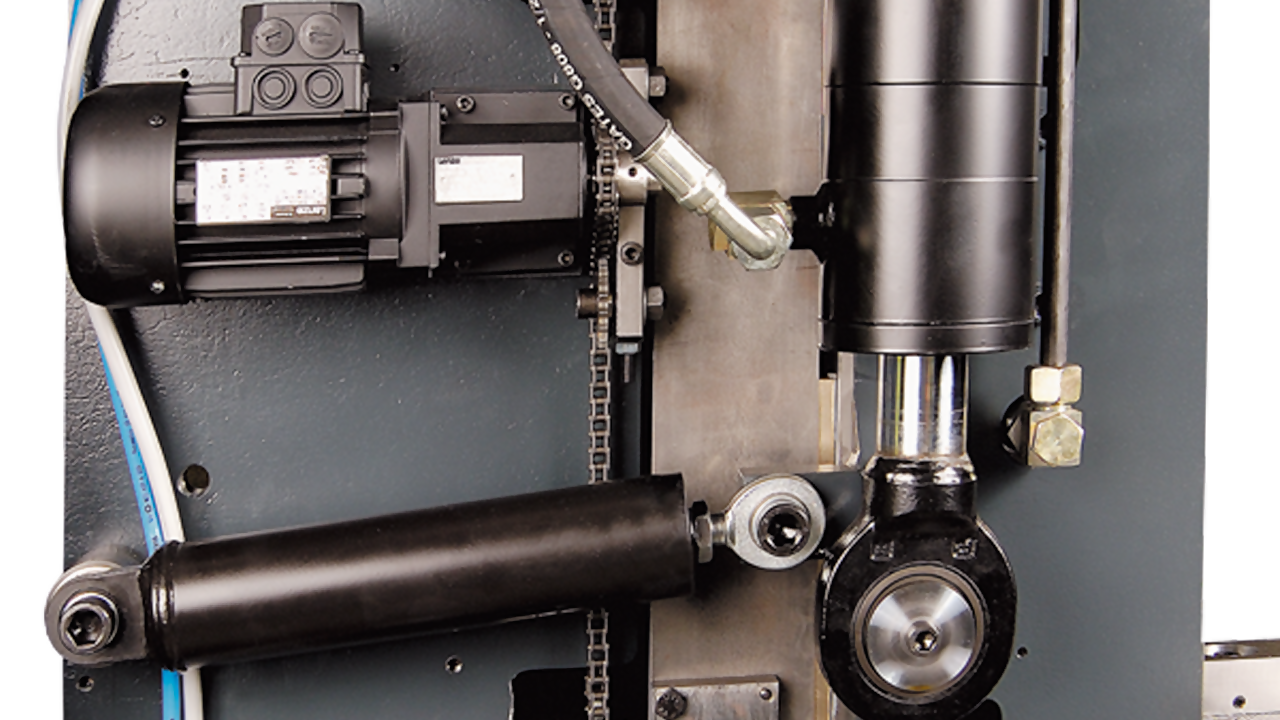

The robust hydraulic systems in the SafanDarley M-Shear are controlled by modern electronics. This means that the regulatory mechanism has evolved from hydraulic to electronic technology. A successful E-volution that increases both your productivity and the quality of your products.

The standard equipment for the SafanDarley M-Shear includes blades with four cutting edges, on both the top and bottom. Your shearing is done very economically because blade wear is spread over the blade’s entire length, thanks to the programmable starting position of the cutting beam.

The servo-electronic motor powering the hybrid drive only runs when the cutting beam is in motion. This yields two advantages: energy saving and the cutting cycle produces low noise levels. In combination with the solid construction and the modular assembly, makes this M-Shear a superior guillotine shear.

Request a demonstration

Thank you

Thank you for your request

Technical specifications

| Model | Cutting capacity | Bending length in mm | Main motor power in kW | No. of strokes/min (stroke length max. cutting edge) | No. of strokes/min (stroke length min. cutting edge) | Cutting angle 0.5°-max (°) | Backgauge reach in inches | Backgauge speed in mm/sec | No. of hold-down pads | Weight in kg |

|---|---|---|---|---|---|---|---|---|---|---|

| 125-4 | 4 | 1250 | 11 | 48 | 110 | 2 | 1000 | 200 | 10 | 4000 |

| 205-6 | 6 | 2050 | 11 | 32 | 84 | 2 | 1000 | 200 | 14 | 4200 |

| 310-6 | 6 | 3100 | 11 | 24 | 80 | 2 | 1000 | 200 | 20 | 6200 |

| 610-6 | 6 | 6100 | 15 | 12 | 30 | 1,5 | 1000 | 200 | 36 | 18800 |

| 430-8 | 8 | 4300 | 15 | 13 | 30 | 1,5 | 1000 | 200 | 26 | 14500 |

| 310-10 | 10 | 3100 | 15 | 12 | 30 | 2 | 1000 | 200 | 20 | 9800 |

| 610-10 | 10 | 6100 | 18,5 | 5 | 16 | 2 | 1000 | 200 | 36 | 28000 |

| 310-16 | 16 | 3100 | 30 | 12 | 34 | 3 | 1250 | 125 | 20 | 12500 |

| 430-16 | 16 | 4300 | 30 | 8 | 26 | 3 | 1250 | 125 | 26 | 21500 |

- Touch Screen control, type TS200 with TFT colour monitor on a swivel arm

- CNC controlled backgauge

- Automatic clearance and cutting-angle adjustment

- Automatic retraction of the backgauge for narrow strip widths

- Adjustable starting and end stopping position for the entire length of the cutting beam

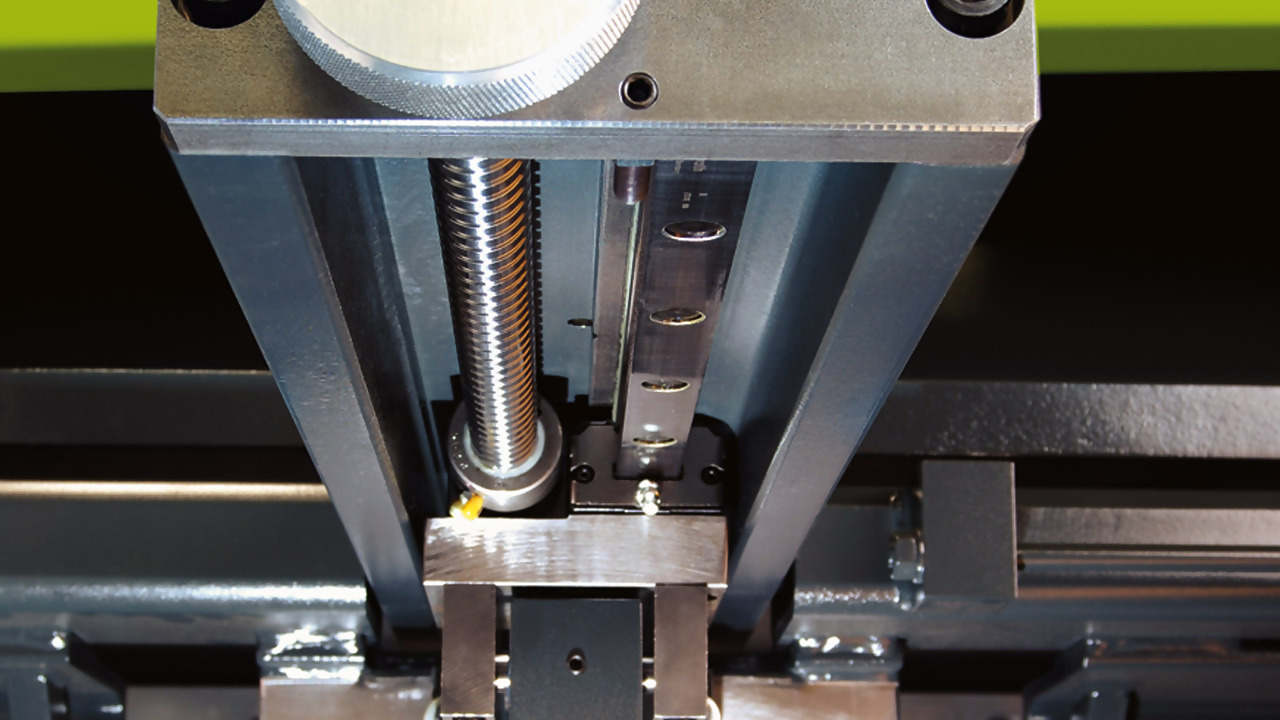

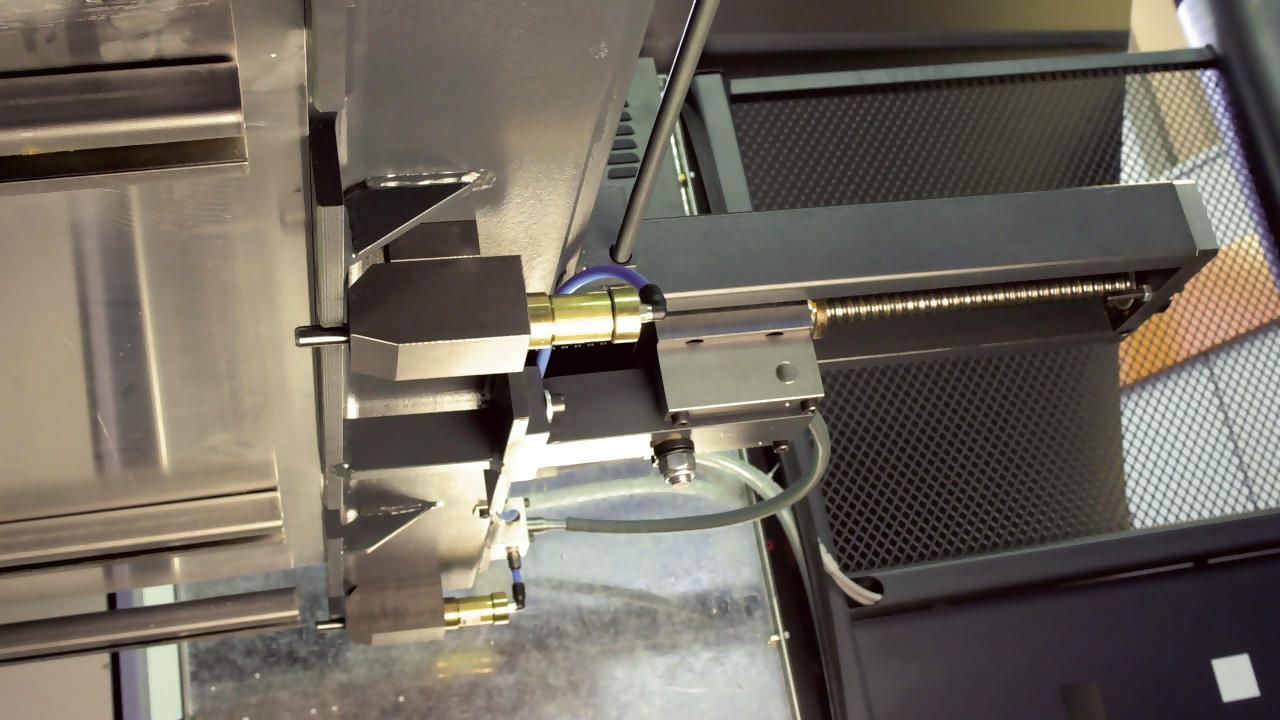

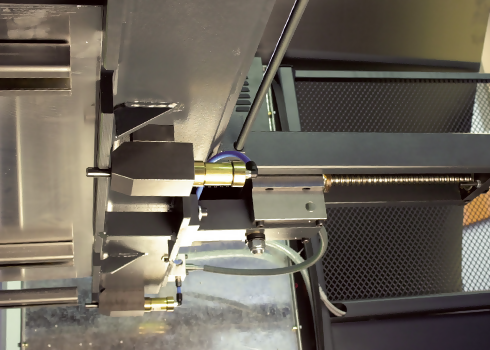

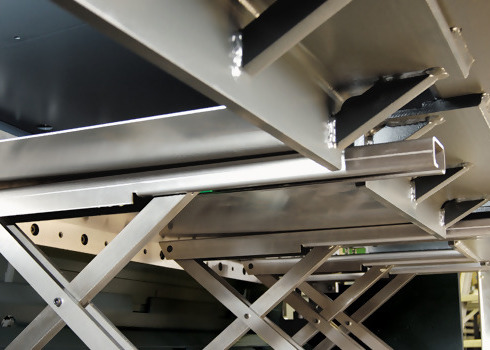

- Backgauge supports equipped with ball screws and play free linear guides

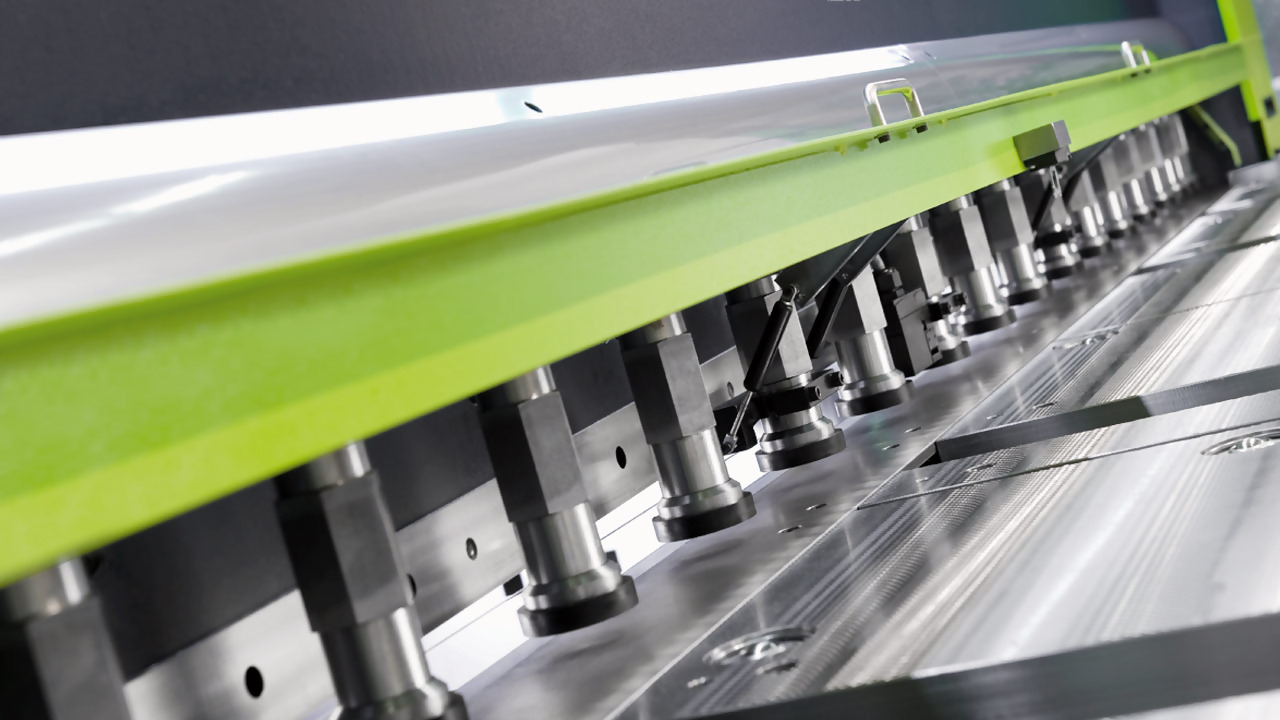

- Maintenance free cutting beam guides

- Fine adjustment of backgauge parallelism

- Adjustable hold down cylinders

- Push-on adiprene covers for the hold down cylinders

- Blades with 4 cutting edges, suitable for shearing stainless steel (max. tensile strength 750 N/mm2)

- Cutting line lighting with cutting line indication

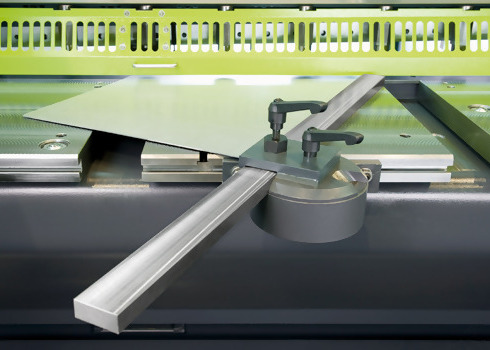

- 2 support arms, adjustable over the entire width of the table (length is approx. 1200 mm from the cutting line)

- 2 squaring guides on the right and left sides of the table (across the entire table width)

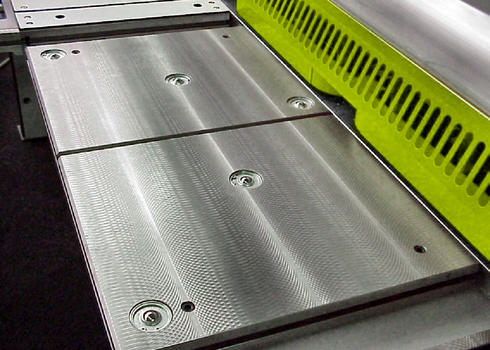

- 2 rulers in the table

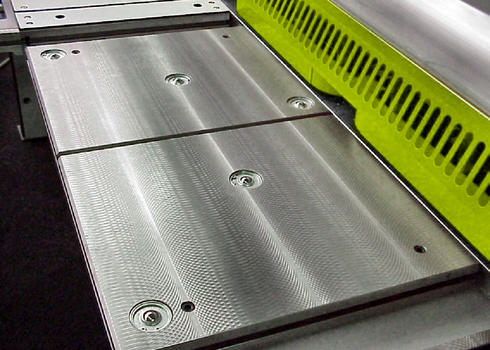

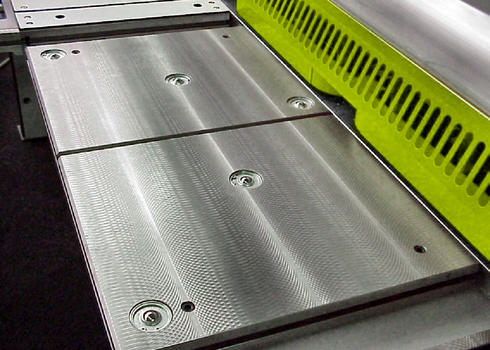

- T slots and hand slots spread across the width of the table

- 1 T slot on the front of the table

- 2 spring-action stops

- Key switch (3 positions)

- Safety features complying with the European Machine Directive

- Finger guard

- Filled oil reservoir • Foundation plates

Available accessories

« Back to the overview

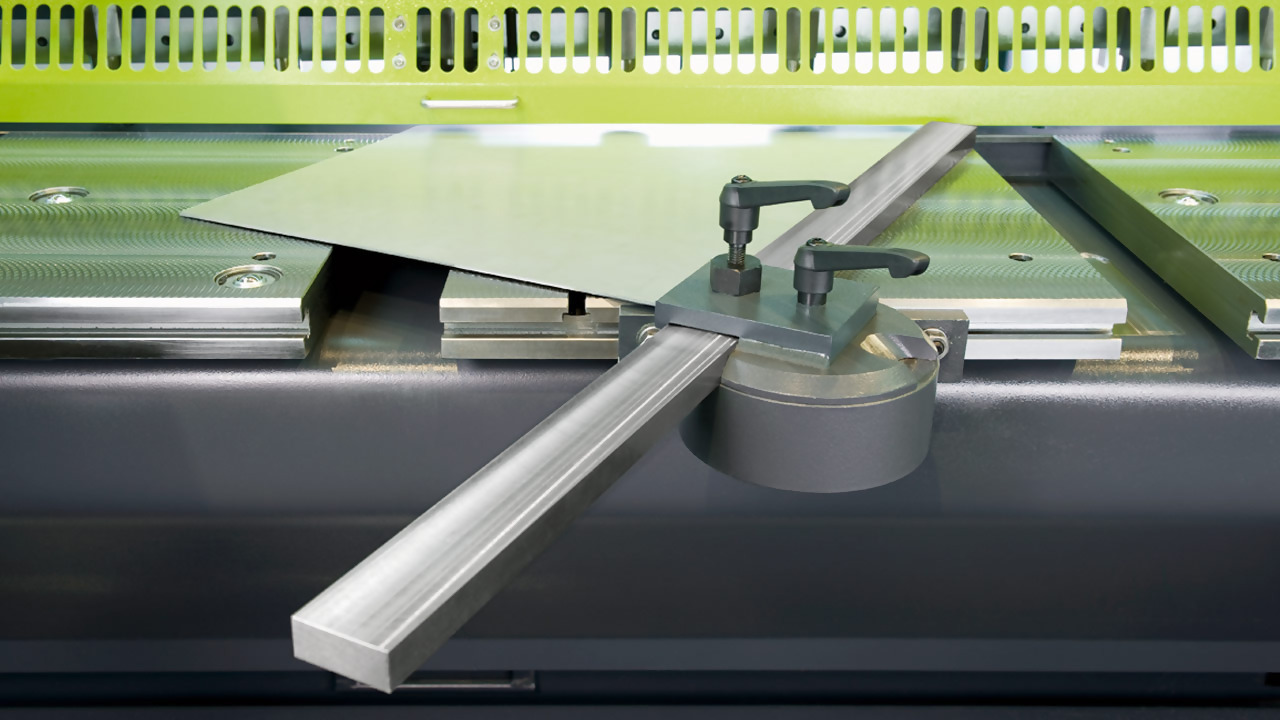

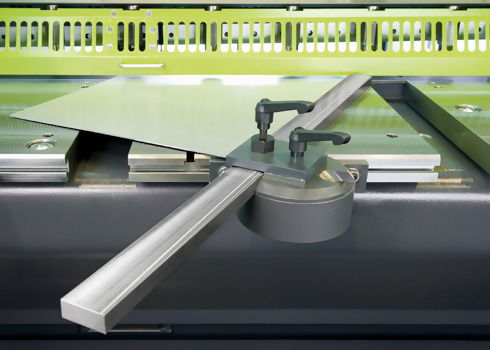

- Adjustable corner

- Extended support arms and optional Stops for the support arms

- Light screen safety or

- Folding finger guard

- Ball casters in the table

- Scratch-free table cover

- Pneumatic installation for holding plates up

- Return To Sender function

- Fingers for holding plates up in back gauge beam

- Scrap sorter (with/without sorting valve)

- Scrap removal cart with our without folding bottom

- Extended back gauge reach

- Pneumatic folding back gauge

- with stacker

- without stacker

Advantages:

- Guiding the plate back

- Less damage

- Reverse cutting

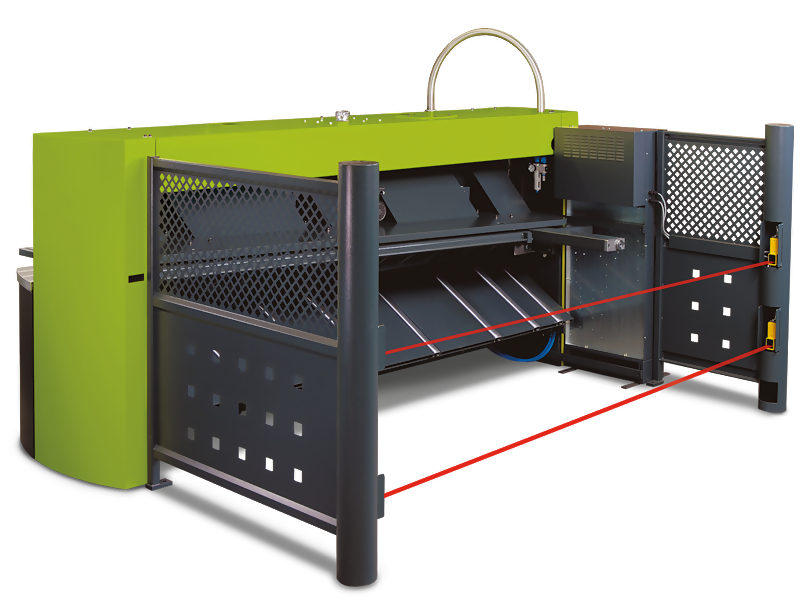

Safetyfirst

The safety features of the SafanDarley M-Shear fully satisfy the European Machine Directive. The cutting beam drive is equipped with block hydraulics. All visible high-pressure lines are protected. The shear has extensive guards protecting the back and sides.