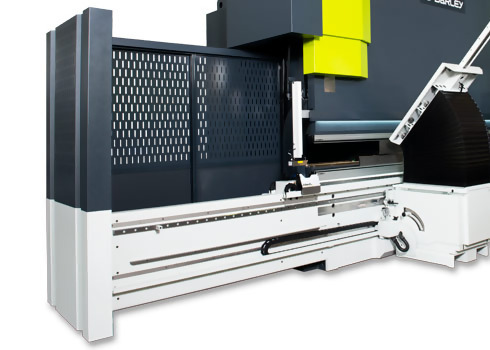

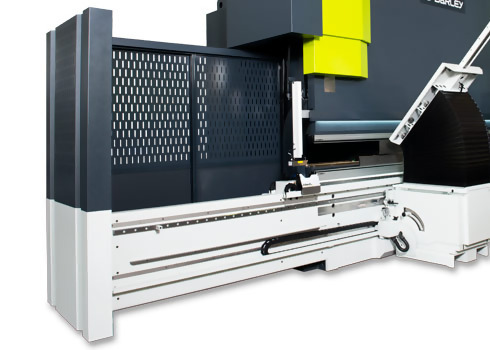

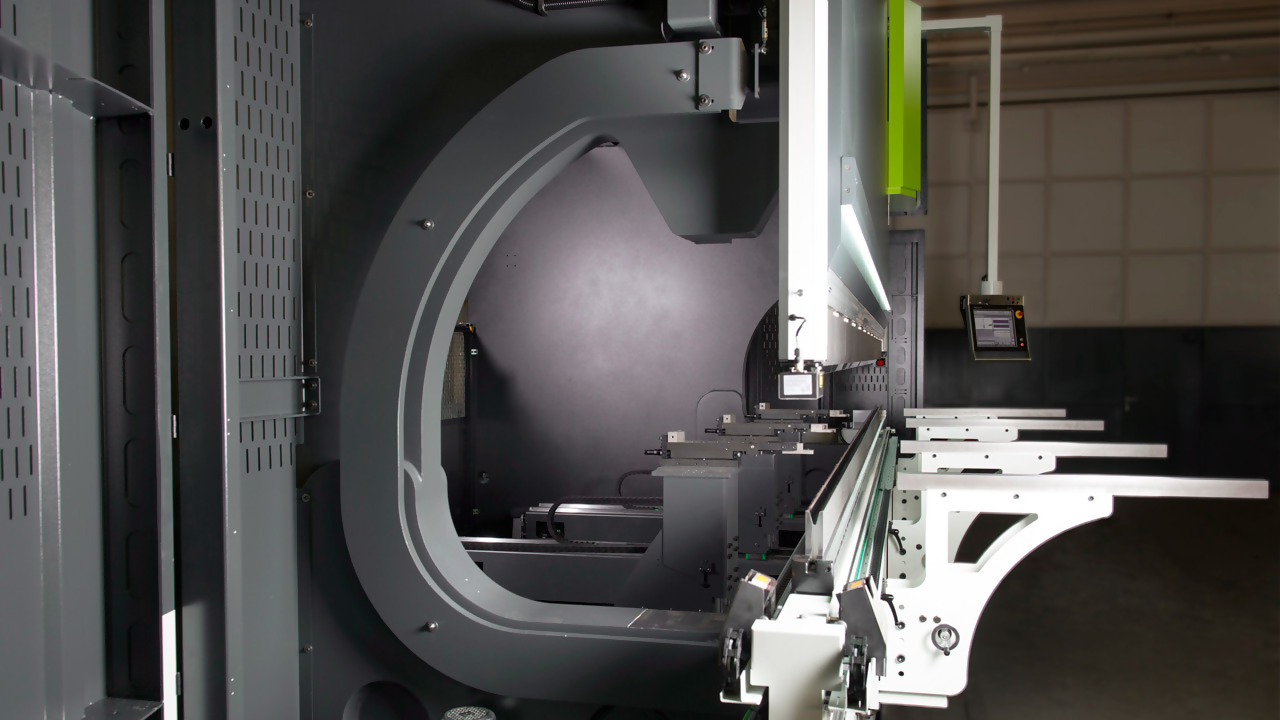

H-Brake HD 700-1000T

Hydraulic press brakes with maximum efficiency

The HD machine with HD options

- High-end press brake with Y-Axis repeat accuracy (0,01mm)

- Robust & durable construction

- Quick setup and fast cycle times

- High level of freedom with 2 different types of control types

- Flexible throat & Q dimensions

- Custom made solutions

- Versatile bending aids

- A large variety of tonnages and lengths

- Wide range of flexible tandem solutions

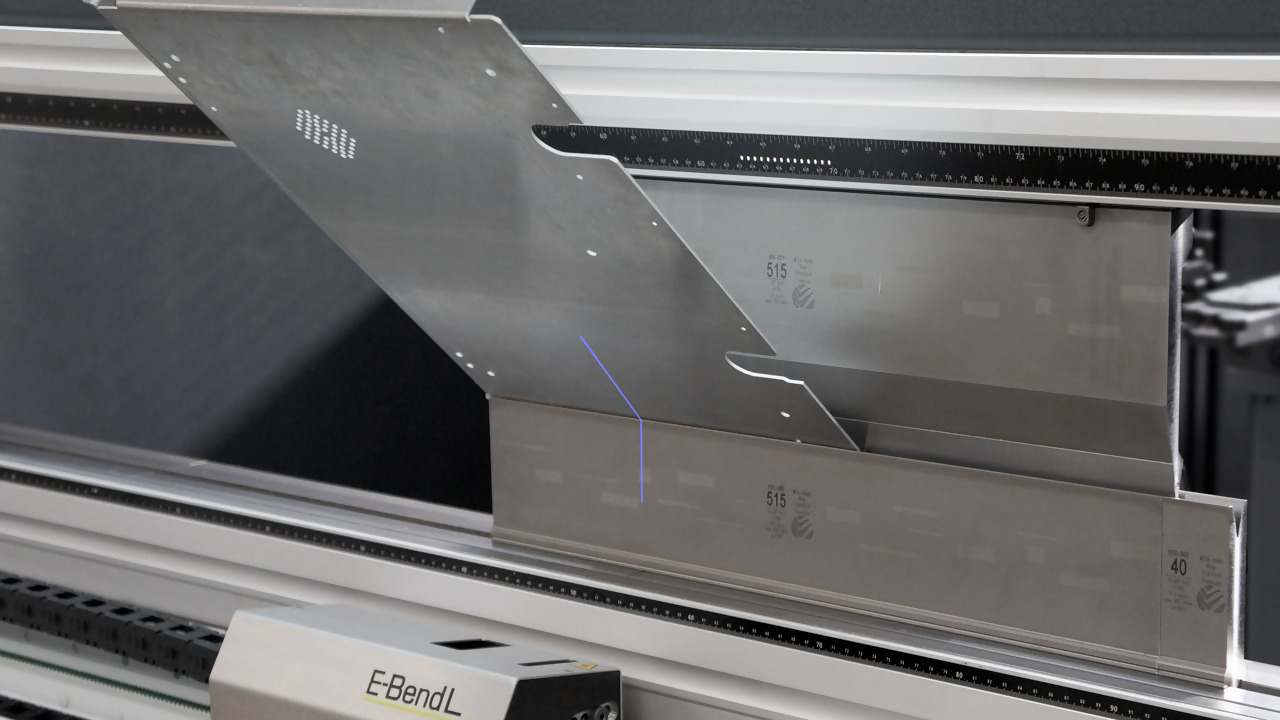

- The first bend is always perfect ( within 0,5°) with the E-bend L

Integrated safety

Work fast without risk: SafanDarley makes that a reality with the safety system integrated within the controls. It works with a safety light screen that is automatically directed from the SafanDarley E-Controls.

Request a demonstration

Thank you

Thank you for your request

Technical specifications

| Model | Tonnage | BowLength | Pressure force in kN | Bending length in mm | Maximum stroke in mm | Q-dimension in mm | Closing speed in mm/sec | Bending speed max. in mm/sec | Return speed in mm/sec | Motor power in kW | Weight in kg |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 500-4200 | 500 | 4200 | - | - | - | - | - | - | - | - | - |

| 500-5100 | 500 | 5100 | - | - | - | - | - | - | - | - | - |

| 500-6200 | 500 | 6200 | - | - | - | - | - | - | - | - | - |

| 600-4200 | 600 | 4200 | - | - | - | - | - | - | - | - | - |

| 600-5100 | 600 | 5100 | - | - | - | - | - | - | - | - | - |

| 600-6100 | 600 | 6100 | - | - | - | - | - | - | - | - | - |

| 600-8200 | 600 | 8200 | - | - | - | - | - | - | - | - | - |

| 800-4200 | 800 | 4200 | - | - | - | - | - | - | - | - | - |

| 800-5100 | 800 | 5100 | - | - | - | - | - | - | - | - | - |

| 800-6200 | 800 | 6200 | - | - | - | - | - | - | - | - | - |

| 800-8200 | 800 | 8200 | - | - | - | - | - | - | - | - | - |

| 1000-6200 | 1000 | 6200 | - | - | - | - | - | - | - | - | - |

| 1000-8200 | 1000 | 8200 | - | - | - | - | - | - | - | - | - |

| 1250-6200 | 1250 | 6200 | - | - | - | - | - | - | - | - | - |

Standard edition

- Delem DA 66T 2D or E-Control EC20 controls

- Controls mounted on a swivelling arm on the right side of the machine

- Y1/Y2 axis are CNC-powered

- X axis is CNC-powered

- R axis is CNC-powered

- Z1 and Z2 axis are controlled manually

- Wila NSCL-II Premium top tool adaptor equipped with mechanical clamping,

- with a maximum load of 250T/mtr top-bearing and 300 T/mtr shoulder-bearing

- and CNC deep-hardened tool clamping

- Wila NSCR-II Premium CNC-powered crowning using mechanical clamping,

- CNC deep-hardened tool clamping, maximum load 300 T/mtr, Tx/Ty alignment

- 2 support arms (300mm)

- LazerSafe light beam protection, type LZS-004 (Delem)

- Programmable and integrated safety light screen (E-Control)

- Foot pedal including “Hold To Run”-function

- Work area lighting on the front and rear side of the machine

- Electronic installation of mains connection 3/N/PE 50 Hz 230/400 VAC

- Machine is designed in accordance with the prevailing CE standards

Available accessories

« Back to the overview

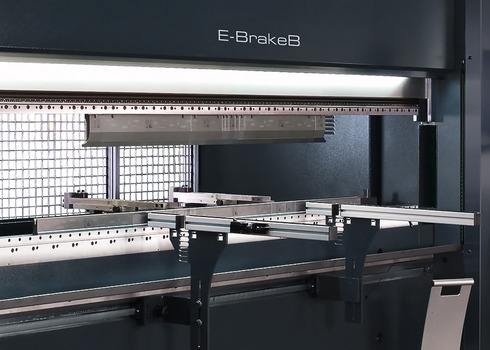

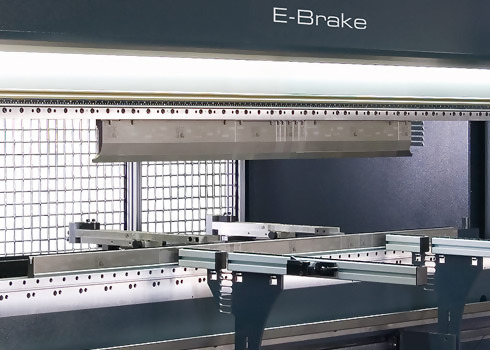

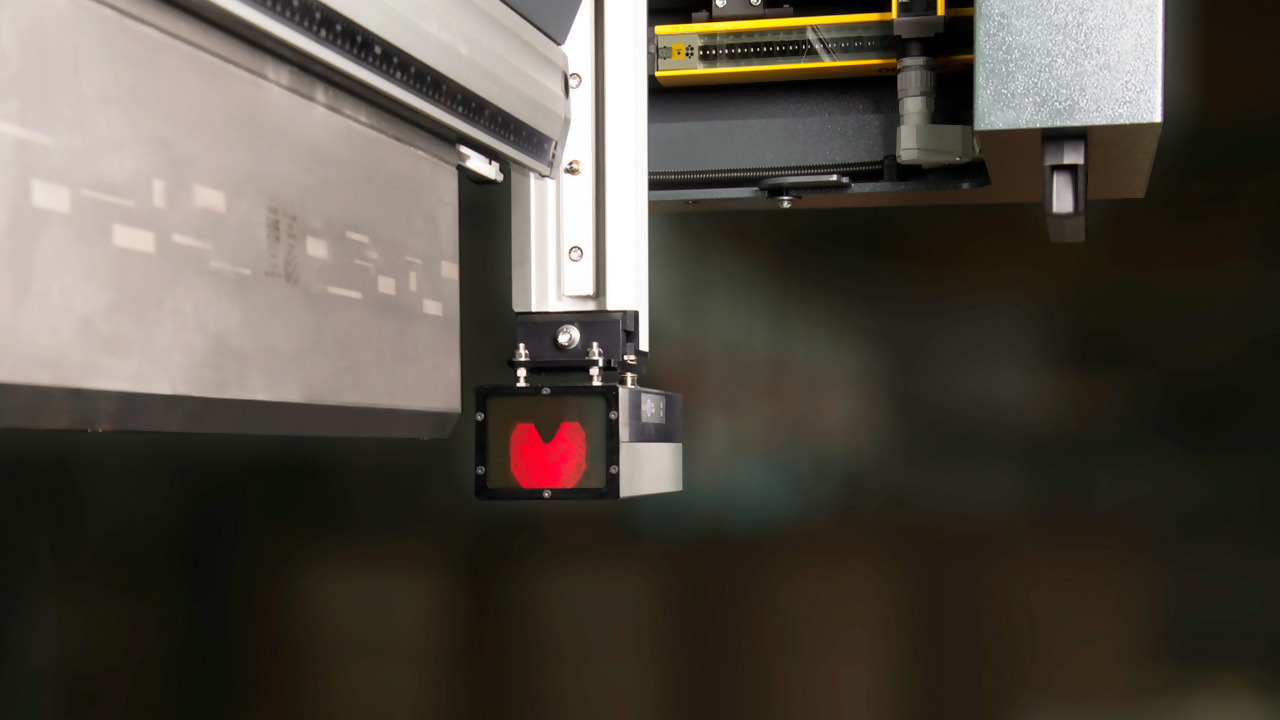

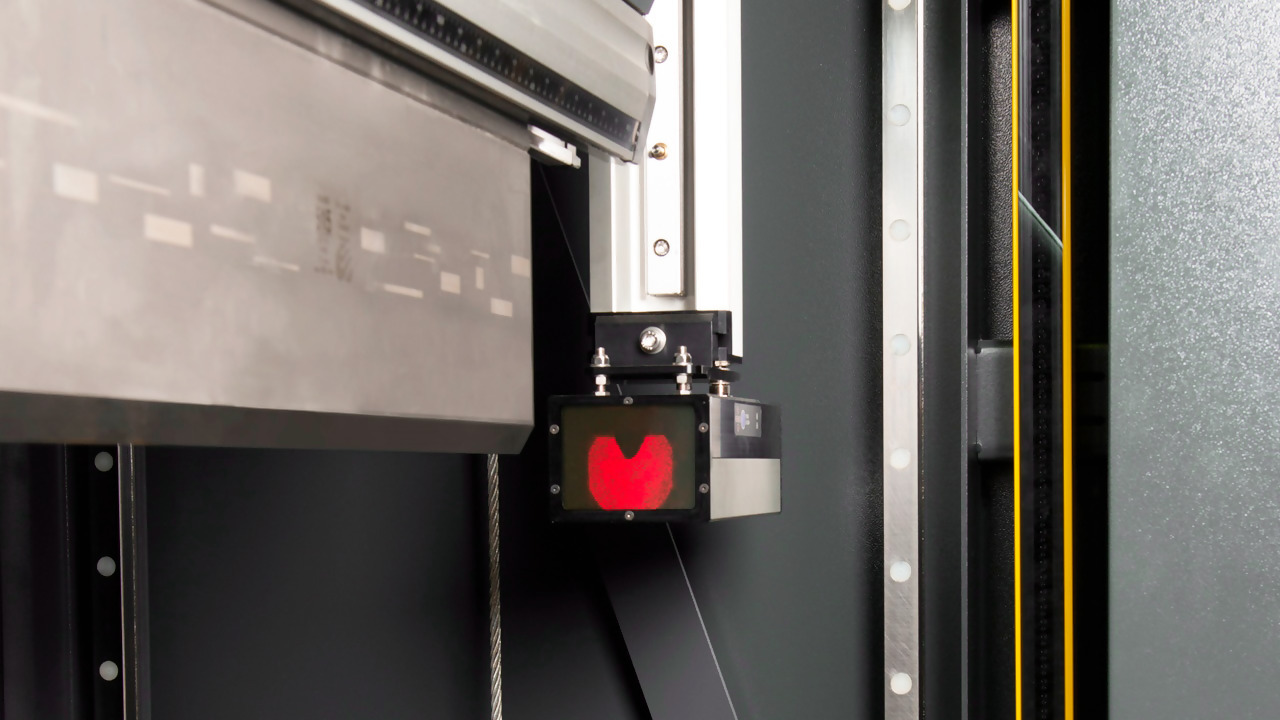

E-Bend L Blue

CNC-Controlled laser angle measurement system on linear guiding. The system consists of two laser sensors on each side of the table and continuously displays and corrects the position of the Y axis on the basis of the actual angle of the product. Guaranteeing that the end product has the highest degree of angle precision.

Bending aid

Using the SafanDarley Bending Aids increases overall production efficiency and reduces the requirement for two operators when handling larger sheet metal parts.

Options:

- I-Mate: maximum plate weight 100kg

- E-Mate 2000: maximum plate weight 200 kg*

* available for Ultra version

Options:

- I-Mate: maximum plate weight 100kg

- E-Mate 2000: maximum plate weight 200 kg*

* available for Ultra version

Bekijk opties

Measurement

To guarantee optimum accuracy and consistency, it is possible to expand your press brake with the following measuring systems:

Options:

- E-bend S: sheet thickness measuring system

- E-bend L Blue: angle measuring system*

*available for Ultra version

Options:

- E-bend S: sheet thickness measuring system

- E-bend L Blue: angle measuring system*

*available for Ultra version

Bekijk opties

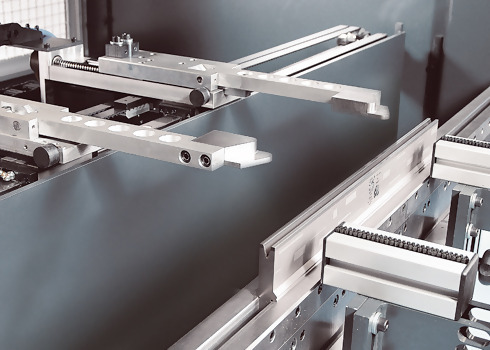

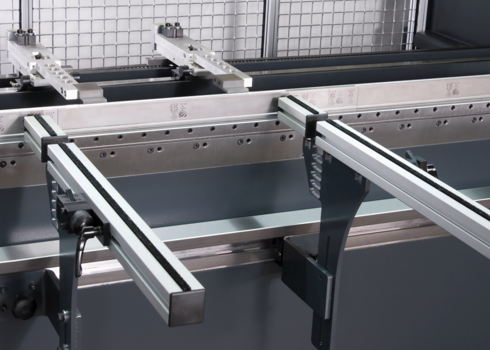

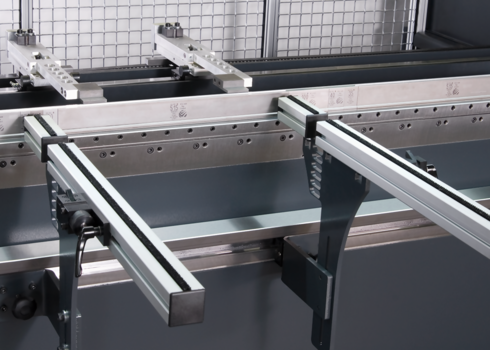

Support arms press brakes

Press brake sheet support arms are essential in metal fabrication, providing stability, accuracy, and safety during bending. The support arms keep metal sheets flat, prevent deformation, and ensure precise results.

Options:

- Movable support arms

- Moveable support arms, height manual adjustable

- Moveable support arms, height pneumatically adjustable

Options:

- Movable support arms

- Moveable support arms, height manual adjustable

- Moveable support arms, height pneumatically adjustable

Bekijk opties

Tool system

SafanDarley is open to work with any type or brand when it comes to tool adapters.

Options:

- New Standard

- European Style

Extra option:

- Smart Tool Locator

Options:

- New Standard

- European Style

Extra option:

- Smart Tool Locator

Bekijk opties

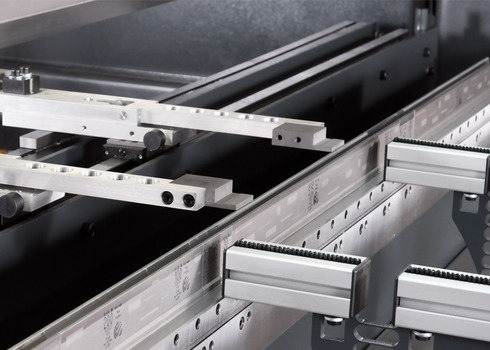

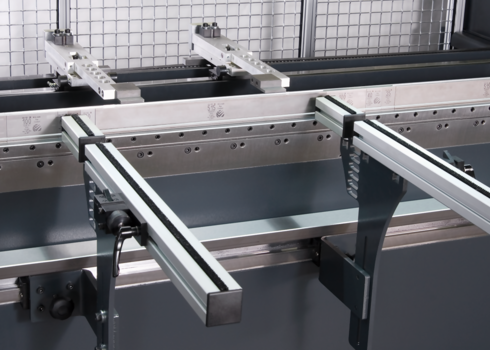

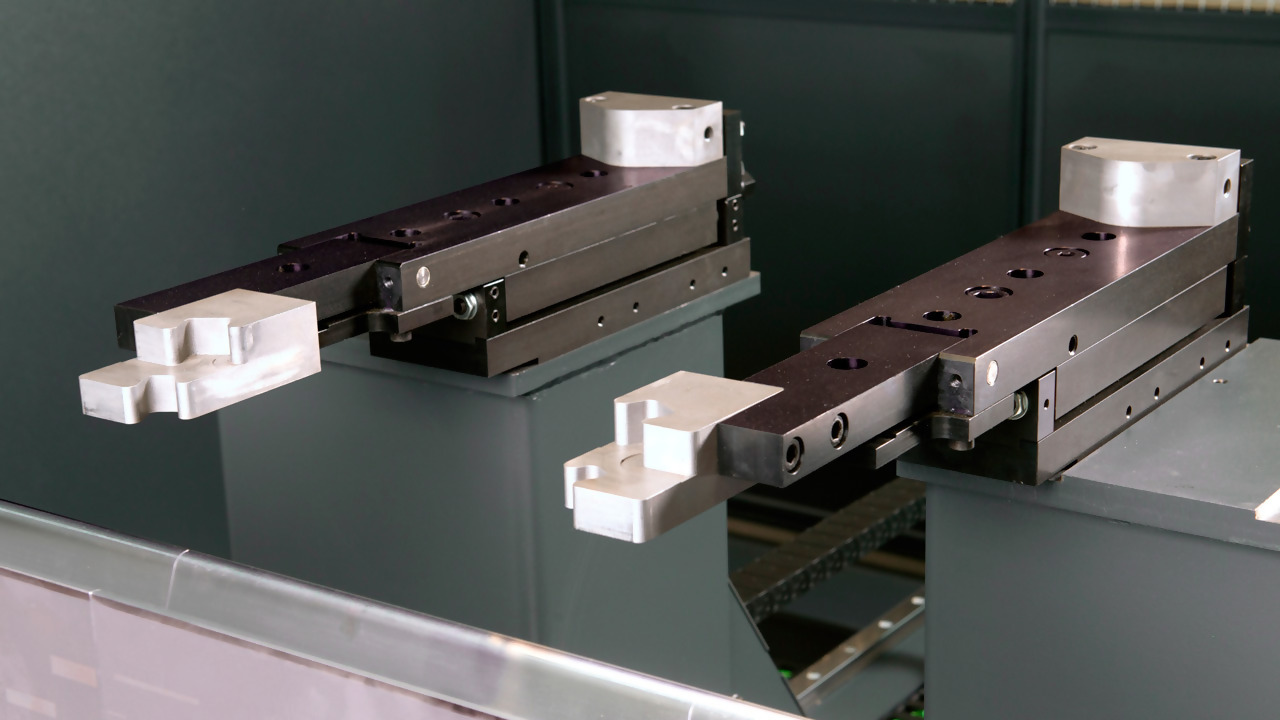

Back gauge system

The back gauge system serves as a mould for various plate material products. Choice of back gauge systems is depending on the complexity of the product to be bent.

Options:

- CNC-Controlled Z1+Z2 axis

- CNC-Controlled Delta X axis

- CNC-Controlled 3D back gauge*

*available for Ultra version

Options:

- CNC-Controlled Z1+Z2 axis

- CNC-Controlled Delta X axis

- CNC-Controlled 3D back gauge*

*available for Ultra version

Bekijk opties

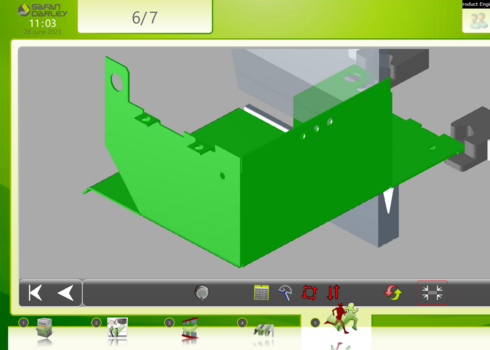

Control

SafanDarley's control systems focus on automating difficult and mundane tasks, reducing cycle time and improving the quality produced. All with little or no effort from the operator. The touch screen concept is therefore the most functional and intuitive Man-Machine interface in the sheet-metal working industry.

Options:

- EC20*

- EC3D

- Dual landscape screen

*standard for E-Brake Ultra and H-iBrake

Options:

- EC20*

- EC3D

- Dual landscape screen

*standard for E-Brake Ultra and H-iBrake

Bekijk opties

Parking station

Options:

- Parking station on the left of the machine.

- Parking station on the right of the machine.

- Parking station on the left of the machine.

- Parking station on the right of the machine.

Bekijk opties

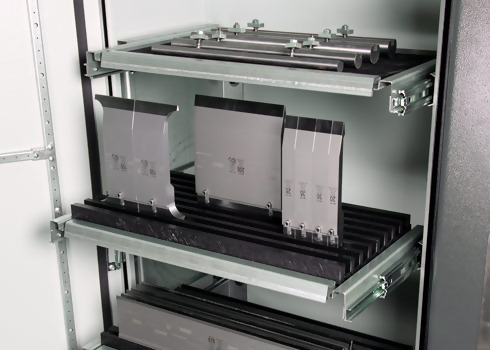

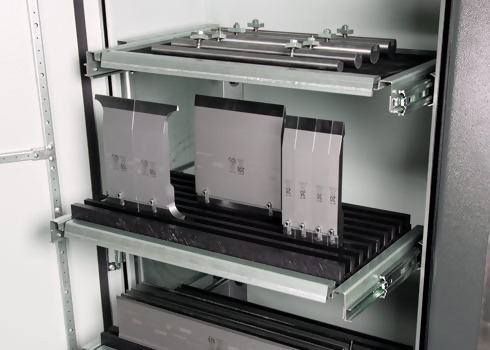

Materials cupboard

Options:

- Materials cupboard on the machine

- Materials cupboard on the machine

Bekijk opties

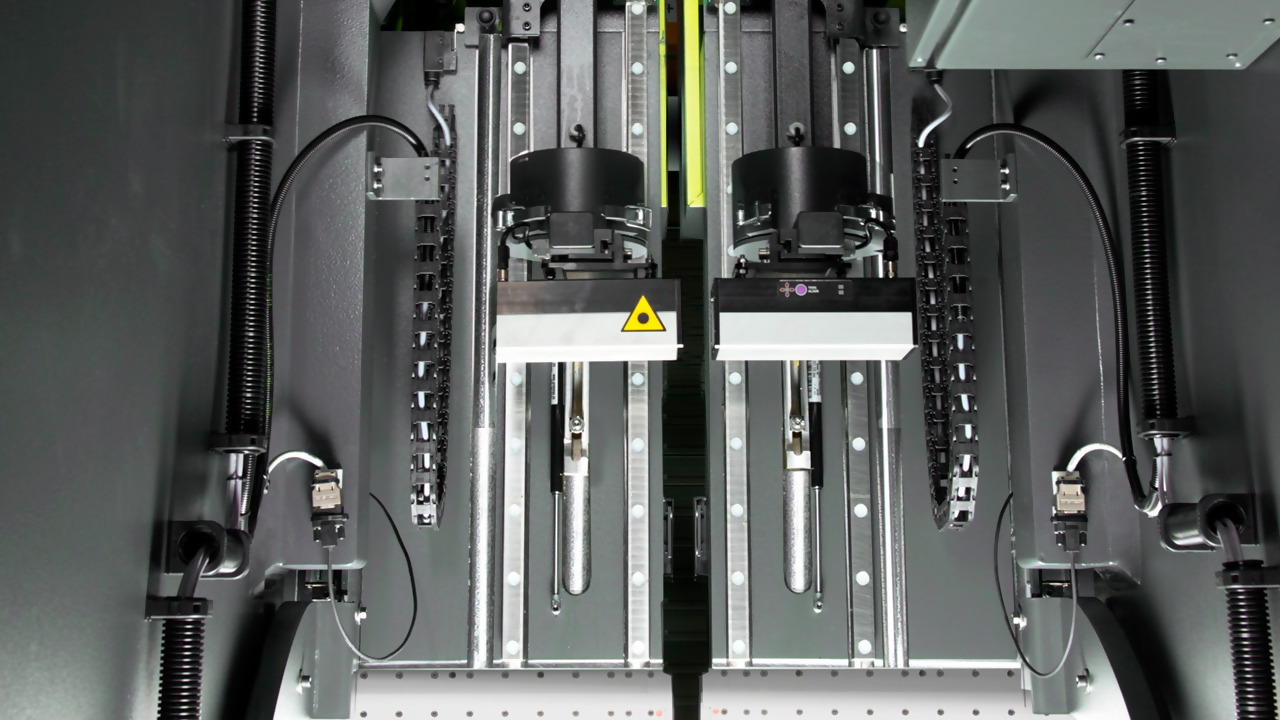

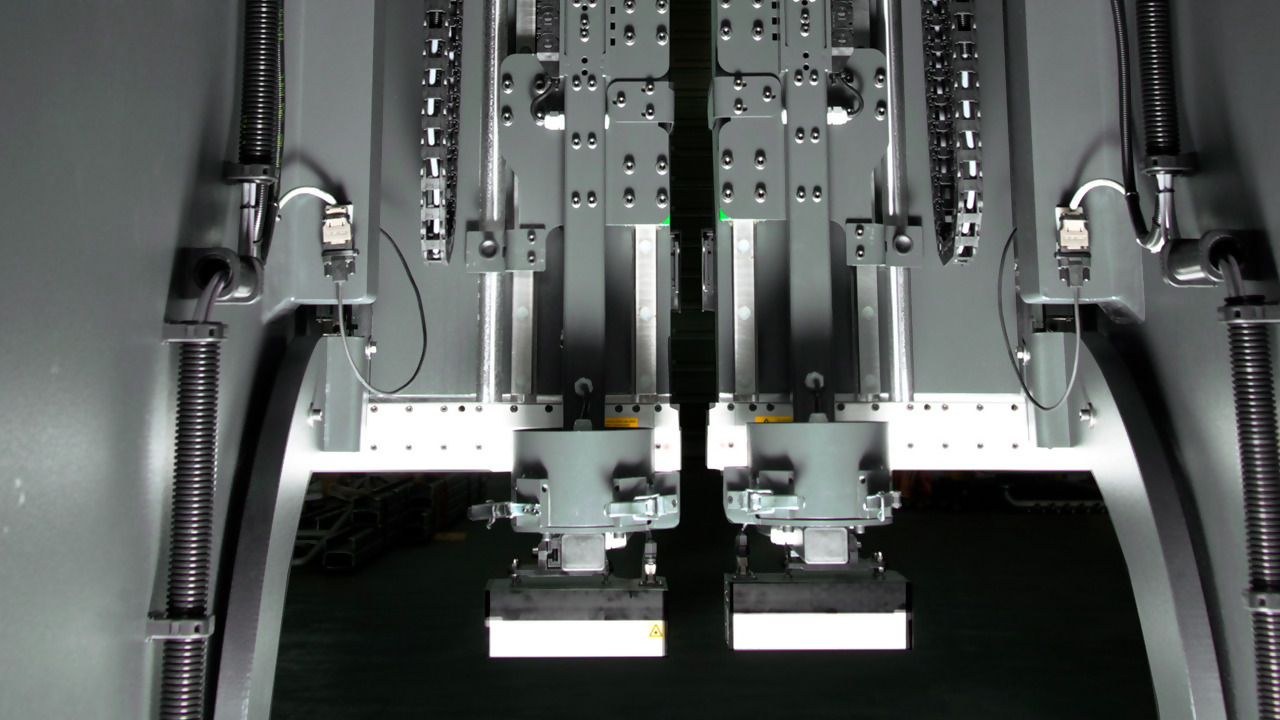

CNC-Controlled 3D back gauge

Including:

depth adjustment of the back gauge fingers (X1+X2)

height adjustment of the back gauge fingers (R1+R2)

width adjustment of the back gauge fingers (Z1+Z2)

depth adjustment of the back gauge fingers (X1+X2)

height adjustment of the back gauge fingers (R1+R2)

width adjustment of the back gauge fingers (Z1+Z2)

CNC-Controlled Delta X axis

The setting of the Delta X axis determines the horizontal conversion of a single Z2 back gauge finger.

CNC-Controlled Z1+Z2 axis

The setting of the Z1+Z2 axis determines the horizontal widht adjustment of the back gauge fingers.

Dual landscape screen

By working with a double display you are able to run two applications on a single display, enabling to create a paperless working environment. The screens, fitted on a swiffelarm, are in height adjustable and rotable outside the working area.

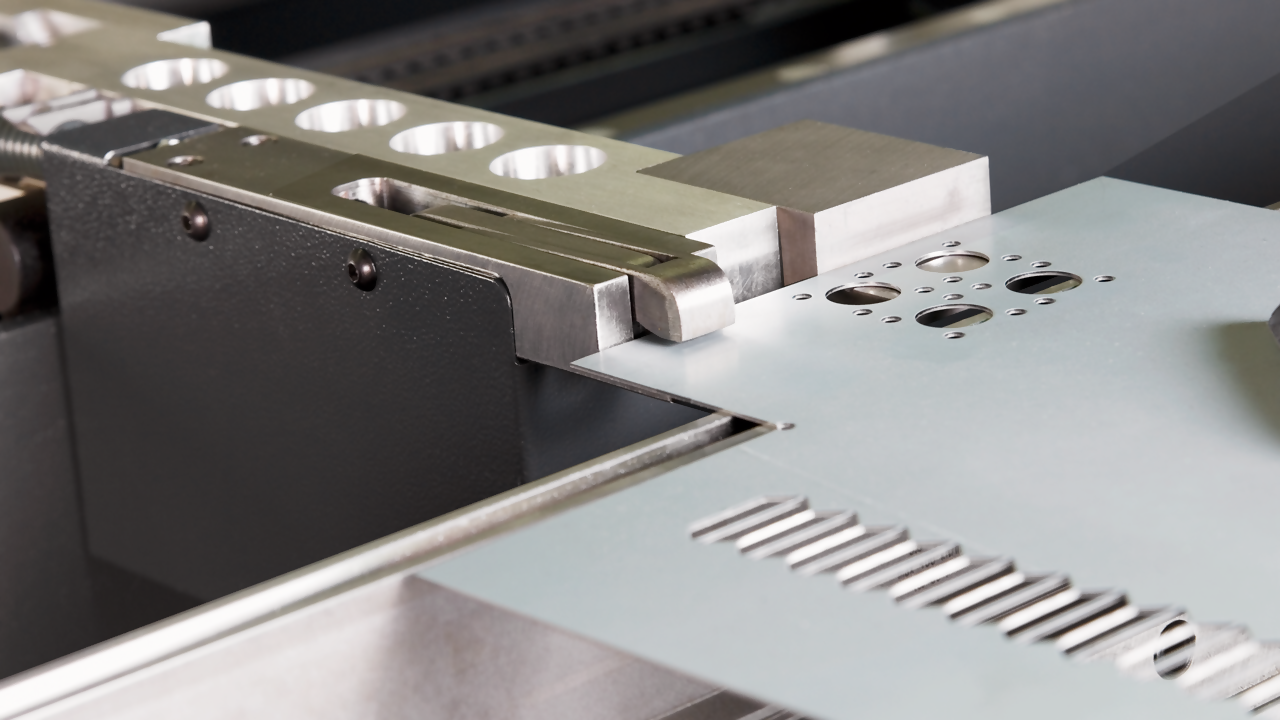

E-Bend S

The CNC-Controlled sheet thickness measuring system measures the plate thickness accurate to one hundredth and is programmable per bed step. Measuring takes less than a second and the thickness data in the controller is adjusted immediately. In the controler's database, all thickness measurements are tracked and graphically plotted.

E-Mate 2000

Bending aid E-Mate 2000 supports and follows the plate very carefully throughout the entire bending process. The height and V size are variable and can easily be adjusted to the bending aid.

The E-Mate 2000 has a lifting capacity of 2000Nm with a plate weight of 200kg and is movable on a lineair rail and can easily be removed by a linge operator.

The E-Mate 2000 has a lifting capacity of 2000Nm with a plate weight of 200kg and is movable on a lineair rail and can easily be removed by a linge operator.

EC3D powered by AutoPOL

The functionality of EC3D allows the user to work with both numeric and 2D-graphic programming and has the ability to import 3D sheet metal models and automatically generate a complet bending program by means of the touch screen control directly at the machine with te Dual Screen option can be fitted with EC3D.

European Style Tool adapters

European Style clamping (only in combination with a Q size of 650 mm). European Style tool intake.

I-Mate

This intelligent bending aid stands out for its user-friendliness, ergonomics and quality.

I-Mate provides automatically calculated support during the entire bending sequence, from flat sheet to the programmed bending angle based on material type, sheet thickness and lower tool parameters.

I-Mate has a lifting moment of 750 Nm with a maximum sheet weight of 22Lbs (100 kg).

I-Mate provides automatically calculated support during the entire bending sequence, from flat sheet to the programmed bending angle based on material type, sheet thickness and lower tool parameters.

I-Mate has a lifting moment of 750 Nm with a maximum sheet weight of 22Lbs (100 kg).

Materials cupboard

Materials cupboard on the machine. Storage facility for – for example – tools or documentation.

Moveable support arms

Fixed arms can be moved along the machine.

Moveable support arms, height pneumatically adjustable

Fixed arms can be moved along the machine, and the height can be adjusted pneumatically.

Moveable support arms, heigth manual adjustable

Fixed arms can be moved along the machine, and the height can be adjusted with a hand wheel.

New Standard Tool adapters

New Standard NSCL-l HC pro hydraulic tool clamp system. Quick exchange system for vertical loading and unloading through safety click in tools.

Parking station Left

Parking station on the left of the machine. Parking station for the benefit of bending aids and/or support arms. The bending aids and/or support arms can be placed on the left or right side on the outside of the machine.

Smart Tool Locator

The Smart Tool Locator increases your press brake productivity by using LEDs to show exact tool placement in the tool holder. It also guides operators on back gauge and sheet metal positioning, enhancing speed, precision, and convenience.

Complete Touch Screen convenience

The SafanDarley E-Control is fully touch screen, whereby the only buttons visible on the 21” screen are those that are needed during operation. The controls simply run on a PC under Microsoft Windows®, the software was developed based on Microsoft.net Framework.

Heavy duty backgauge fingers

1000 mm gap in the side frame

Lightguard open

Lightguard closed

Lazersafe in tandem mode

Lazersafe in single machine mode

9 axis backgauge

E Bend S

E-Bend L Blue

Commissioning H-Brake 800T

H-Brake Ultra