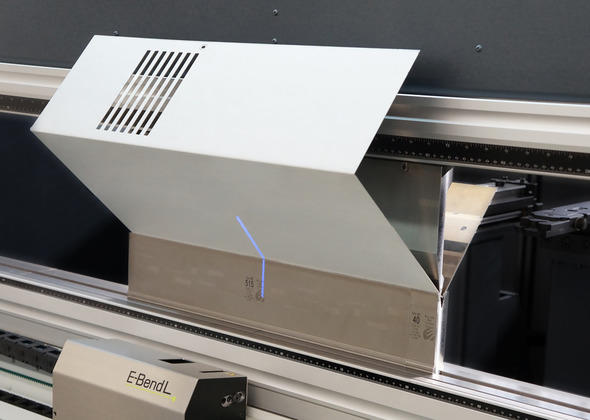

E-Bend L Blue

More accurate and efficient working thanks tonew laser sensors

The new blue laser sensors offer an important benefit compared to the usual red. Red laser light has an almost identical wavelength to natural light, which means the measurement is often affected by local conditions. The blue light spectrum of the E-Bend L Blue is much easier to distinguish from “natural” light, so reflections and sunlight do not interfere with the measurement. In addition, the new sensors can perform many more measurements per second (in combination with the new operating platform on the E-Control). As a result, the system responds to measurements at an earlier stage and enables faster and more accurate working.

Request a demonstration

Thank you

Thank you for your request

Fasterbending process, shorter production time

In the case of angle measurement with spring-back, the E-Bend L Blue measures at one, or three positions during the bending process, corrects the crowning axis, Y1 and Y2 and measures the spring-back. This information is then stored in the database. In the case of an angle measurement with database the bending process can take place more quickly without loss of production time.

3 typesof angle measurements

• Angle measurement with spring-back measurement

• Angle measurement with database

• Angle measurement with learned bending