New version AutoPOL bending simulation software launched

New version AutoPOL

Recently the latest version of the AutoPOL offline bending simulation software has been launched. This version contains a number of new features that make the offline programming of a press brake even more efficient. All registered users have already been able to download the latest version to further optimise production.

Offline angle measurement programming

It is now possible to program the SafanDarley E-Bend L angle measurement system offline with AutoPOL. The intuitive user-friendliness of AutoPOL is also reflected in this new development. The angle measuring system is easy to program by selecting the desired measuring method, after which the sensors will be programmed to the correct position. If the desired position is not available, AutoPOL prompts the user to take action. This prevents erroneous measurements at an early stage. Programming the angle measurement function offline eliminates the programming time on the machine.

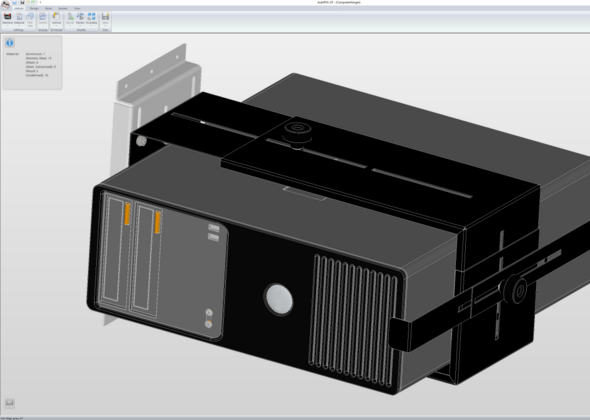

Dissecting 3D sheet metal assemblies

Another development in the AutoPOL software is the ability to automatically analyze 3D sheet metal assemblies. The optional AutoPOL Batch & Remote function has made automatic processing of multiple single 3D parts possible for some time, now this functionality has been extended with the automatic processing of 3D sheet metal assemblies. Unlike previously, this extension is not only available in the Batch & Remote add-on, but this functionality is also present in the Bendsim module so that all registered AutoPOL users can use it.

A 3D sheet metal assembly drawing can be opened in the software in the usual, way. The AutoPOL software can then analyze this assembly, leaving all the properties of the individual parts intact and can, if desired, be taken over for production control. After analyzing an assembly drawing, the bending tools can be automatically selected (per sheet metal part) and the bending sequence determined. With the optional AutoPOL Batch & Remote function, AutoPOL determines the ideal production sequence of the various sheet metal parts with the fewest tool changes. As a result, machine downtime can be kept to a minimum, which means that work can be done even more efficiently.

Back to the overview

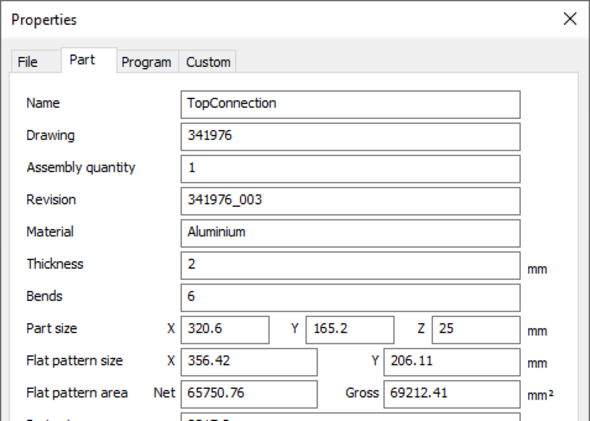

Recognise and assign part properties

Another new development is the import, management and sharing of CAD-CAM properties throughout the bending simulation process. All properties, such as information about file, sheet metal part, bending program and product specific information can be accessed using the “AutoPOL Industry 4.0 Data Sharing protocol”.

With this function, the above information can be integrated with ERP/MRP/MES systems to be used for automatic generation of quotations, planning etc and release to production.

Back to the overviewBenefits of offline programming with AutoPOL software

- Saving programming time on the machine

- Ease of use

- Correct calculations of sheet deflections and back gauge positions

- First time right, no faulty products

- Graphical bending simulation for many machine controls available

- Clear instructions for the press brake operator

- Shorter changeover time

- Feasibility of manufacture checked at an early stage

AutoPOL demo

Would you like to know if offline programming in your production process will contribute to more efficient production? Or do you want more information about the new features? Contact one of our sales advisors or request a demo using the form below.

Request a demonstration

Thank you

Thank you for your request

Read more

news

Last year we employed 7 students who followed a work-learning course with the REMO West-Twente training institute in Rijssen (NL). The students worked in a variety of production departments within our company, designed to compliment their training. All 7 students have recently received their diplomas.

Entrepreneur Wesley van Rietschoten started the company Rietcon in Spijkenisse four years ago. He recently invested in a new SafanDarley Press brake and Guillotine. Production is growing and the factory space is already becoming too small. “We are looking for bigger premises,” says the entrepreneur. At 37 years old, Van Rietschoten is quite a young entrepreneur. But he has already made his mark during his 15 years in the sheet metal sector.