Blechexpo 2019

Blechexpo 2019

The E-volution in sheet metal working continues to progress towards a factory that is fully controlled and managed digitally in order to create a process that is as efficient as possible. During BlechExpo 2019 in Stuttgart, SafanDarley will present a complete programme of solutions with respect to sheet metal working. As the inventor of the electronic press brake, SafanDarley will also showcase the very first E-Brake from 1995. How has the E-Brake helped to create an efficient working environment? Find out during BlechExpo.

E-Brake Ultra series with I-Mate

At BlechExpo, SafanDarley will also demonstrate the high-end E-Brake Ultra series. The E-Brake 50T-2050 Ultra is fitted, as standard, with a CNC crowning system and also has a double screen, which facilitates a paper-free working environment. The E-Brake Ultra can also be fitted with a 3D back-gauge and the patented E-Bend L Blue angle measurement system. The E-Brake 50T-2050 Ultra on demonstration will also be equipped with the latest, intelligent bending aid, called I-Mate. The I-Mate is the ideal CNC-driven bending aid when using options such as the E-bend L Angle measurement system and flattening tool combinations.

H-Brake Hybrid 110T-1600 Ergo

In 2018, SafanDarley introduced the H-Brake Hybrid 110T-1600. This compact powerhouse has an extremely high tonnage range over a small working length. This compact, fast machine is ideally suited for setting small, complex thicker sheet metal parts and is the ideal solution for small spaces. Development of the machine has been ongoing and, as of now, is also available in an Ergonomic variant, which is particularly useful for bending large series. This operating comfort results in higher productivity.

Back to the overview

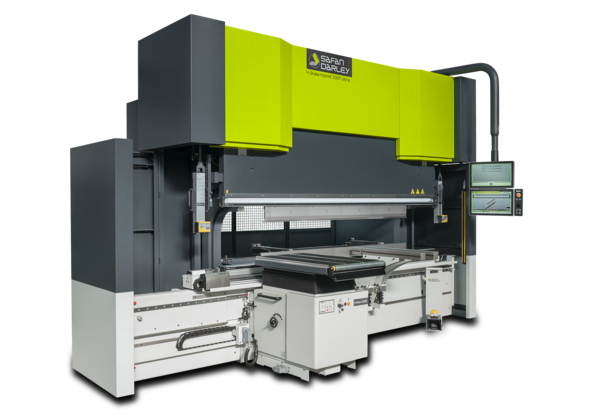

Introduction of H-Brake Hybrid+ 230T Ultra

During BlechExpo, SafanDarley will showcase a new model of Hybrid press brake, the H-Brake Hybrid+ 230T Ultra. The Hybrid+ series is an expansion of the existing Hybrid series and offers higher tonnages but also further benefits. At its core, there is an advanced dual hybrid drive with high return speed, high productivity and low energy consumption. As a result, costs are reduced and CO2 emissions decreased. This machine is an example of sustainable thinking in the Smart Industry.

Back to the overviewE-Brakeexpands Q-size

During BlechExpo, we will present an E-Brake 40T with an extremely large Q-size. The standard E-Brake 40T is equipped with a Q-size of 590 mm; the machine that we will demonstrate at BlechExpo has a Q-size of 1090 mm. This enlarged Q dimension makes it possible to bend products with very tall upstanding sides.

Autopol offline software

One of the highlights during the trade fair will be our unique Autopol offline bending simulation software, a modern 3D-system for programming press brakes offline to unfold 3D CAD models. The optional Batch & Remote functionality enables the automatic processing of multiple components. It significantly reduces programming costs and reports the result of every step in the process. All machines on the stand are linked to a workstation. The entire process, from offline programming, through sending the programs to the machine and then reading out information about the machine’s productivity, is displayed on a dashboard with clear graphics.

Visit SafanDarley

In addition to the innovations mentioned, SafanDarley will also be demonstrating machines from the standard supply range at BlechExpo, such as the E-Brake 35T Premium and the M-Shear 310-6 with return-to-sender function.

Visit SafanDarley at BlechExpo in Stuttgart from 5 to 8 November 2019 in Hall 1, stand 1309

Read more

news

As part of the commitment to the US market and following the successful growth in the Midwest and south east, SafanDarley North America, LLC will be relocating its US facility to Waukesha, Wisconsin.

SafanDarley recently commissioned an H-Brake 800T at Bässler in Olpe (DE). The H-Brake 800T with a working length of 8200 mm has a weight of approximately 95.000 kg. For transport