Product Highlight

Automated Press Brake

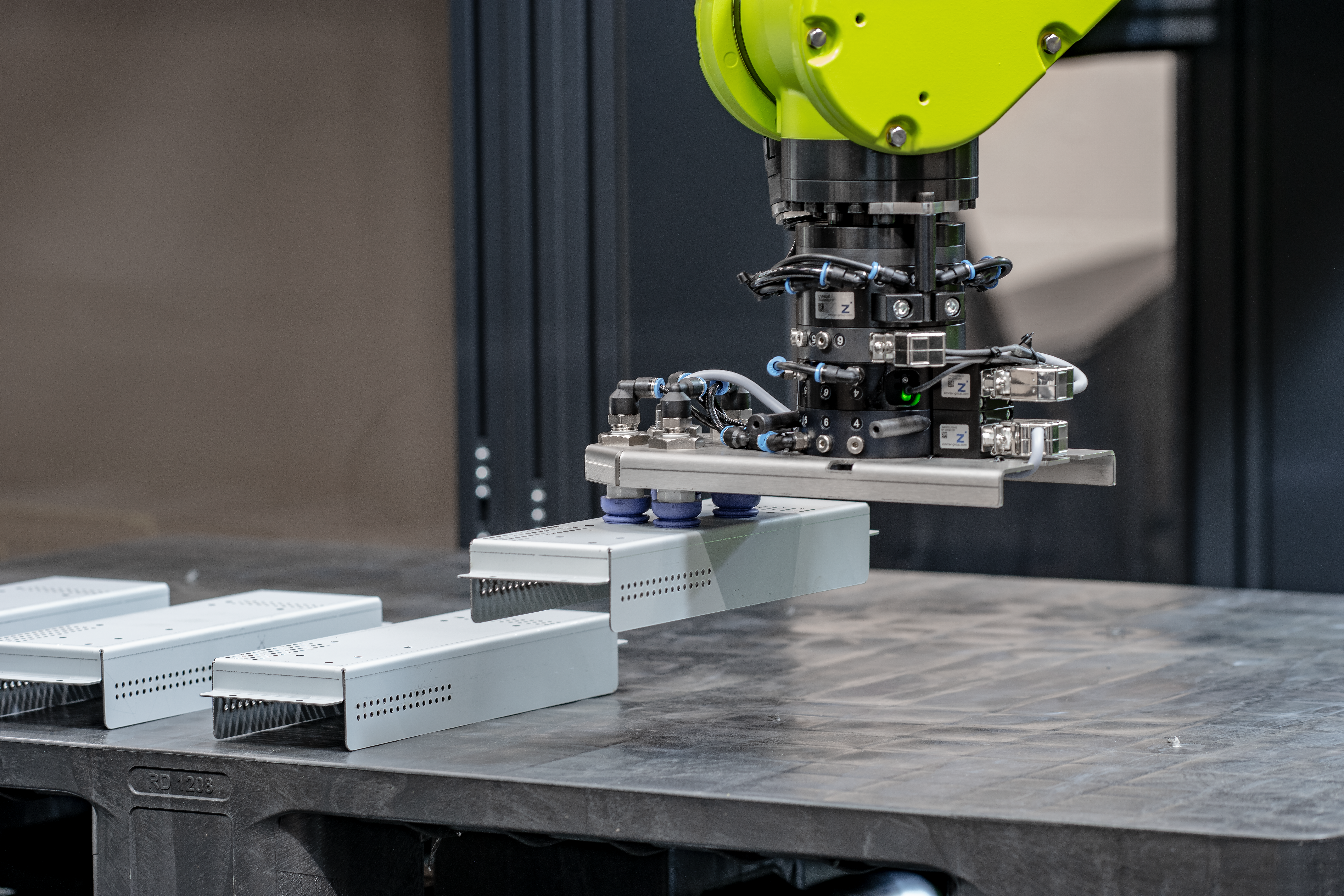

For those requiring automated bending solutions, SafanDarley has a variety options in its product range to choose from. One of these fully automated solutions is the E-Brake Mini Cell 35T-1250, a flexible bending cell, which is perfectly suited for the production of small complex products. This compact press brake has a modular structure that can be constructed as desired with a variety of options or as retro fit at a later date. This allows the E-Brake Mini Cell to be fully configured according to individual customer requirements.

Modular construction

The Mini Cell press brake is equipped with a FANUC robot with a handling capacity of 25 kg, a supply station for four product stacks, a finished parts station and a discharge chute. The Mini Cell can be built to the highest specification, equipped with a multitude of options that further optimise the production process and that requires minimal or no personnel depending on the options chosen.

The Mini Cell can also be equipped with a discharge belt for the scratch-free discharge of finished products outside the cell. The optional pallet management system ensures the automatic supply of an empty pallet for stacking products. As soon as the pallet is full, it is automatically transported outside the cell and a new pallet is introduced.

ASC-Control

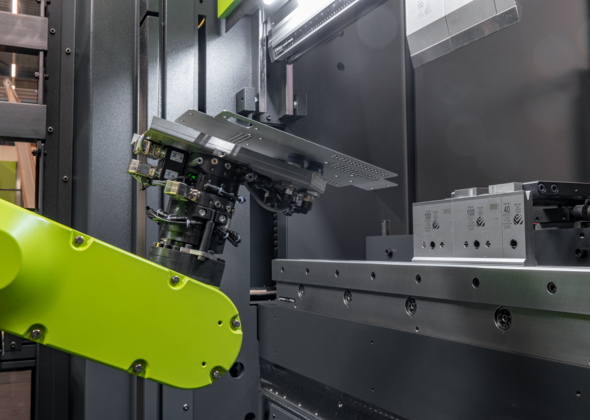

The E-Brake Mini Cell can be equipped with features such as automatic tool change. This makes it possible to switch quickly between different products. It is also possible to bend different products in succession without intermediate programming. With SafanDarley's latest software platform, the ASC-Control, the shortest possible changeover times between products is achieved. The ASC-Control automatically runs the new programs in the robot and the press brake and activates the automatic tool and gripper change. Without any operator intervention, multiple products can be placed in the queue and then processed one by one. Keep an eye on our newsletter for more information and details about our latest robot software platform, the ASC-Control.

Offline control

The E-Brake Mini Cell can be programmed offline with AutoPOL and in combination with the Robobend offline software package, it is possible to simultaneously produce a bending program and a robot program. This saves considerable time due to, among other things, automatic determination of the bending sequence and automatic merging of the bending program and the robot program.

Call me back for personal advice

Thank you

Thank you for your request

Theadvantages at a glance

• 24/7 production capability

• Environmentally friendly, 100% electrically powered

• Quickly change between products

• Constant production

• Simple offline programming

• Small footprint

• Up to 30% higher productivity through electric drive and integration of control and drive motors

• Backgauge can be used over the full working length

• Quiet

• Lower maintenance costs

• Accurate tool change

• Customisable with default options

Request a demonstration

Thank you

Thank you for your request