E-Brake Mini Cell

Compact and complete

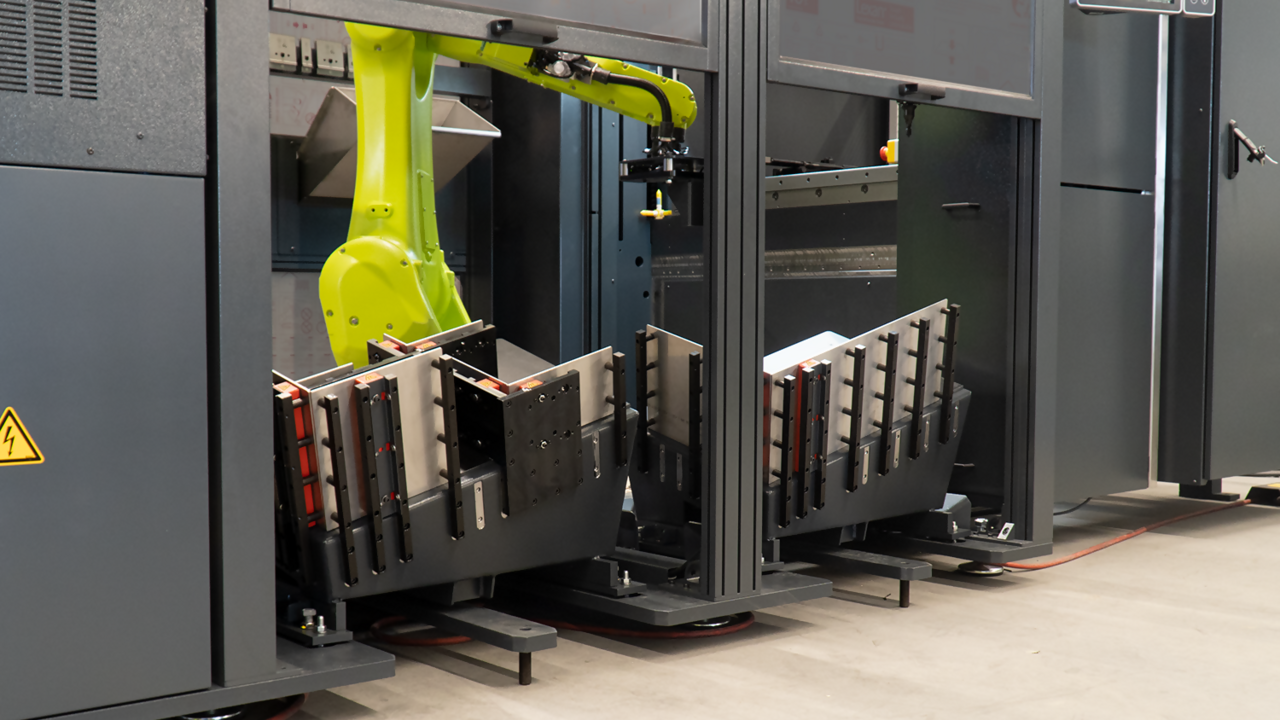

The E-Brake 35T Mini Cell is characterised as a compact automatic flexible bending cell and is equipped with a 25 kg Fanuc Robot based on the SafanDarley E-Brake 35T-1250 press brake. The E-Brake 35T Mini Cell is ideal for fully automatic production of small complex products. It also allows successive bending of different products without intermediate programming. By adding various options, such as: automatic gripper, tool change, reversing stations, infeed and outfeed systems, this machine can be fully configured to customer specifications.

SafanDarley

E-Brake 35T Mini Cell

- Fully Electrical driven Machine

- Fully automatic bending cell

- Decrease of production time

- Up to 50% energy saving

- 25kg payload Robot

- Sheet size up till 600x800 mm

- Small footprint

- Easy offline programming

- User friendly touch screen control

- More production output

- Automatic producing

- Accurate tool change

- Always available for production

- Possible to retrofit options at any time

Optimal efficiency

The E-Brake 35T Mini Cell press brake is equipped with a FANUC robot with a handling weight of 25 kg, 2 infeed stations that can be variably configured, a deposit station and a discharge chute. This fully automated press brake is characterised by its compactness.

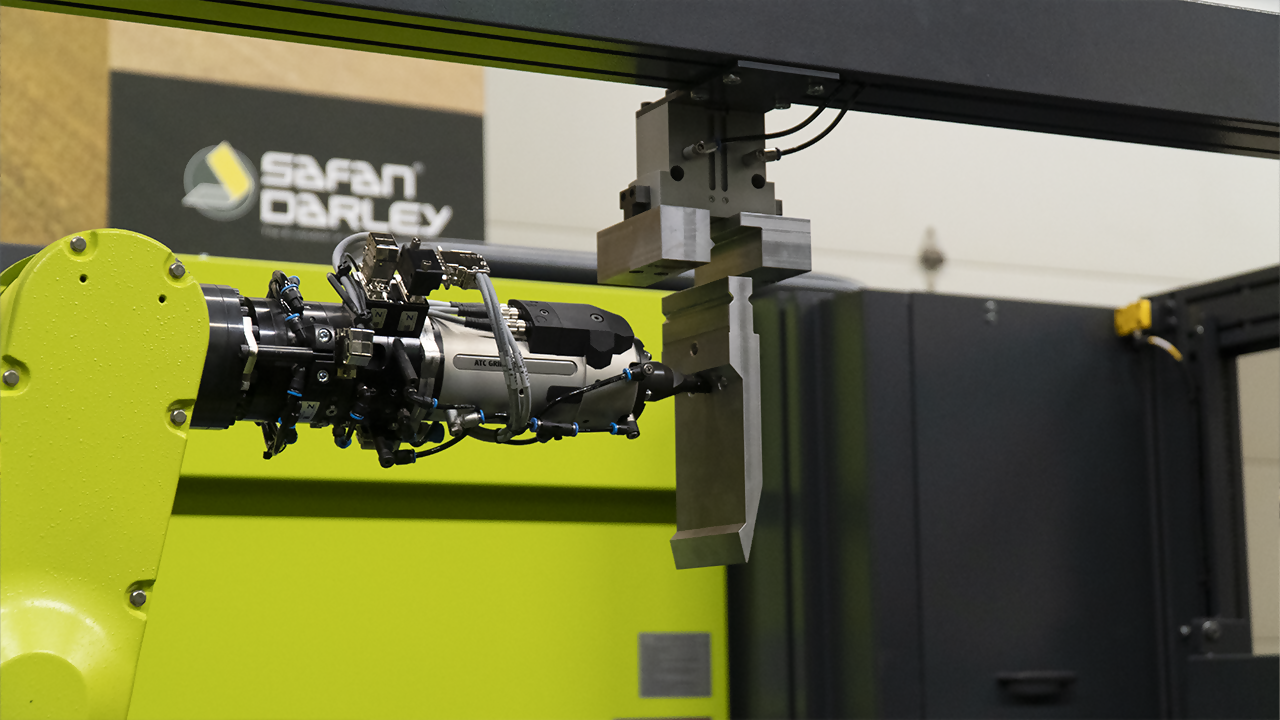

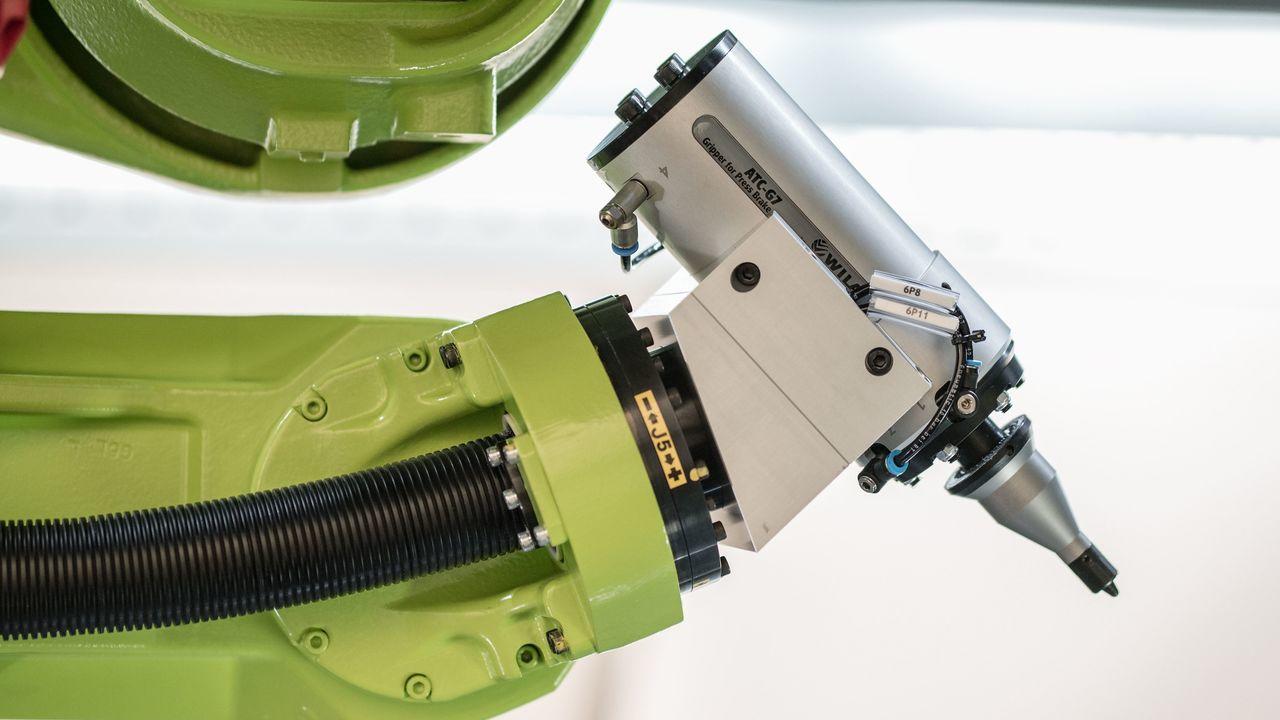

Optionally, the E-Brake 35T Mini Cell can be equipped with an automatic tool change function. This makes it possible to quickly switch between different products. The ToolFlip function allows tools to be rotated as well.

There is a wide variety of additional options which can be added to the cell at any time.

Compact automatic and

flexible bending cell

Since 2023, the E-Brake 35T Premium Mini Cell has been equipped with a double door on the infeed side. This makes it possible to run the Mini Cell for more than 8 hours without human intervention. The addition of an extra product table offers the possibility of doubling the infeed capacity to increase productivity.

As standard, the table stations in the E-Brake 35T Premium Mini Cell are equipped with precision adapters. These adapters guarantee a fixed position, making it possible to have several different tables that can be easily changed. Partly because of this and the application of area scanners in the exchange area, the cell is fully prepared for automatic product/reference table changing by, for example, an AGV, which ensures that the Mini Cell rotates without an operator entering the cell. This makes the E-Brake 35T Premium Mini Cell unique in the market.

Request a demonstration

Thank you

Thank you for your request

Technical specifications

| Model | Tonnage | BowLength | Pressure force in kN | Bending length in mm | Maximum stroke in mm | Q-dimension in mm | Closing speed in mm/sec | Bending speed max. in mm/sec | Return speed in mm/sec | Motor power in kW | Weight in kg |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 35-1250 | 35 | 1250 | 350 | 1250 | 300 | 690 | 180 | 20* | 180 | 11 | - |

- SafanDarley E-Brake 35-1250 Premium

- SafanDarley E-Control EC10

- CNC-controlled Y1 + Y2 axis

- CNC-controlled X axis

- CNC-controlled R axis

- CNC-controlled Z1 + Z2 axis

- Backgauge beam equipped with 2 folding hardened parallel backgauge lugs equipped with sensors

- Upper Tool adapter: NSCL-II MC Premium

- Lower beam equipped with the hardened OB-II MC table TY adjustment

- Q-size: 690 mm

- Hold to Run operating console

- Fanuc M20iB25 robot with the R-30iA controller, DCS module and a rotary distributor to transfer energy to the gripper

- Foundation plate under the E-Brake and all automation components

- Chute for discharge of small products

- 1 Pallet stop. A pallet of 800x600 mm can be placed here with a pallet truck.

- Controlled by SafanDarley ASC-Control

More information

Click here to change your cookie settings

More information

Click here to change your cookie settings