Efficient bending

Efficient bending

A press brake has various characteristics to allow it to bend a product efficiently, and various options can be chosen that will ensure an even more efficient bending process. This article provides information and tips for bending as efficiently as possible, and explains the options step by step.

Efficient bending through:

- Programming time: how much time does it take to enter a bending program?

- Setup time: how quickly can I have my machine ready to start production?

- Bending cycle time: how quickly can I produce my product?

- Production quality: how accurately is my product produced?

- Supplied quality: how accurate are the flat sheet components supplied?

Programming time

There are various methods for entering a bending program into a press brake:

- Numerically on the machine

- Graphically on the machine

- Graphically off-line in bending simulation software on an external PC

When programming on the machine, the machine operator enters the bending program numerically or graphically. A disadvantage of this method is that the machine cannot be operated during the programming. This leads to expensive machine capacity being wasted.

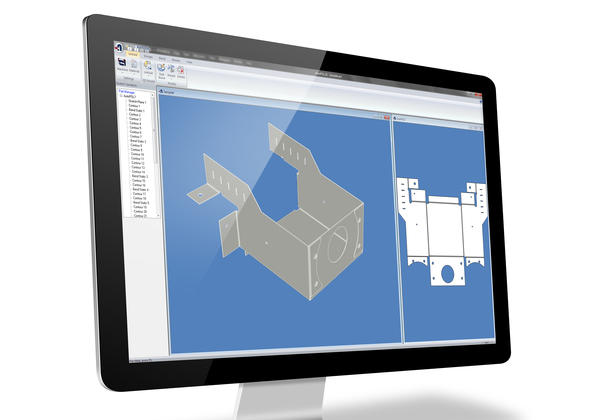

Depending on the complexity of the product, it is becoming more common to opt for graphic off-line programming using bending simulation software.

The great advantages of this are:

- it can be determined at any early stage

- what tool segments are needed and where these have to be placed in the machine

- which machine is needed to produce the part

- whether a product can be made

- During the simulation and preparation of the bending program, no machine capacity is needed (and this is particularly beneficial for one-offs or small batches)

- The calculation of the positions of the various axis in the bending program correspond to the product’s calculated unfolded template (DXF). Thanks to this, no corrections to the bending program are needed, and the first product produced can be used immediately.

SafanDarley provides excellent solutions for this such as the AutoPOL bending simulation software in combination with the EC20 SafanDarley press brake control system. Using this combination, all the necessary numerical and graphical data is programmed automatically and supplied to the press brake operator.

Setup time

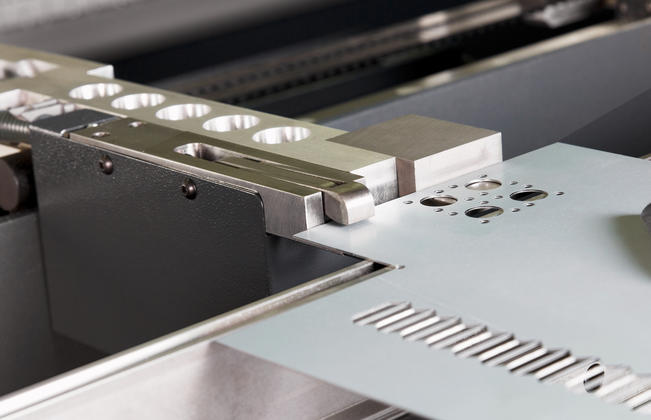

There are various ways of making a machine ready for production. Because most modern press brakes feature CNC controlled back stops, very little time is now wasted on these. Most time is required in collecting and installing the bending tools. Good tool setup documentation is essential here to save valuable time.

Bending tools can be installed in different ways

- from a central tool store in the workshop

- from the machine’s own tool store

- with an automatic tool changer

If tools from a central store are used, this can cause various disruptions:

- tools are used by multiple operators

- tools are not close to the workplace

If tools are used from the machine’s own tool store, the disadvantages listed above no longer apply.

SafanDarley offers tool cabinets that can be used specifically for particular tool types. Special tools that are only used occasionally can be kept in a central store. The positions of the tool segments to be used are indicated in the control system. SafanDarley can install a Smart Tool Locator on the tool holder. Using this, the position of the various tool segments can be indicated by LEDs.

If tools are changed with an automatic tool changer, then they are taken from the machine’s own tool store and installed in the correct bending position on the press brake fully automatically. SafanDarley has developed the SafanDarley iTC for this, which allows the store and the automatic loader to be integrated into a very compact press brake. The operator can carry out other tasks while the press brake tools are installed in their programmed positions.

The SafanDarley press brake and its tools can also be equipped with the TIPS system. This system enables the press brake to identify and read the position of tools. The SafanDarley iTC press brakes are equipped as standard with the TIPS system.

Bending cycle time

A product’s bending cycle time is often expressed as the speed of the press brake’s various axis. While these speeds affect the total bending cycle time, more time can often be saved on other aspects of the press brake.

Factors that affect the total bending cycle time:

- How is the flat product handled? Is the correct side facing upwards, at an ergonomic height, and is the correct edge facing the back stop?

- Are the various accessories (such as support arms, extra stop fingers, bending aids etc.) present and, if required, correctly installed?

- Is the press brake’s safety system (programmable safety light shield, laser beam protection) correctly installed and/or programmed? The CNC controlled safety system available from SafanDarley ensures a significant improvement in cycle times.

- Does the operator receive clear work instructions? Using graphical support of the bending sequence, how the product is to be bent is displayed for each bending step

- Can the finished product be removed quickly and stacked if required?

Production quality

The quality of the bent product may depend on several factors.

- Is the press brake adjusted correctly?

- Back stop, zero position of X, R and Z axis

- Ram parallelism (in X and Y directions)

- Are bending tools clean and undamaged?

- Can the finished product be inspected quickly and properly?

- Is a clear drawing with the correct dimensions present?

- Are the correct measuring tools present?

SafanDarley can supply an extra display with the machine on which the appropriate documentation can be displayed linked to the bending program.

A service maintenance plan can also be provided for performing periodic maintenance and adjustment, if necessary.

Supplied quality

The flat sheet parts supplied may cause deviations during the bending process. Deviations that occur frequently are:

- Variation in sheet thickness, which can cause angle deviations

- Variation in rolling direction, which can cause deviations in angle and leg lengths

- Variation in material batch, which can cause deviations in angle and leg lengths

- Variation in dimensions, due to inaccuracies in the cutting process (geometrical deviations in the laser or die cutting machine) can cause deviations in leg lengths

SafanDarley can deliver press brakes complete with accessories to correct a number of the above deviations. The SafanDarley E-Bend S sheet thickness measuring system corrects variations in sheet thickness. The SafanDarley E-Bend L Blue angle measurement system corrects angle deviations during the bending process.