FABTECH Atlanta

Introduction E-Brake C 200T with Tool Mate

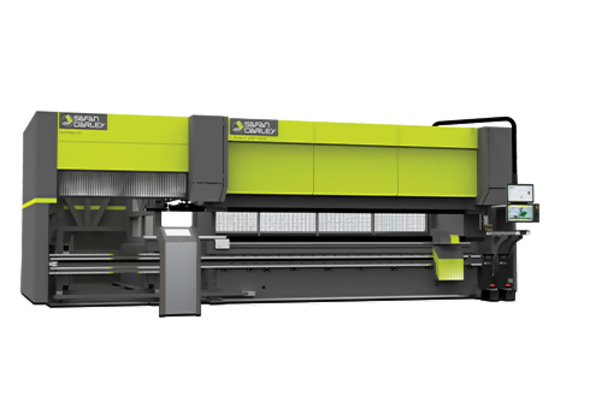

SafanDarley will present the new E-Brake C 200T Ultra with Tool Mate at FabTech in Atlanta, a new C-frame design, electrically drivien press brake with an automatic tool changer. In addition to the new Tool Mate we will also be showing the Mini Cell, a fully self contained automatic bending cell as well as one of our most popular stand alone E-Brakes, the 130T Ultra. All of the examples on the booth are set up to demonstrate how the automation capabilities can set up your production processes to be as efficient as possible.

Introduction E-Brake C 200T Ultra with Tool Mate

In addition to the successful robotic press brake range, SafanDarley is introducing the E-Brake C 200T with Tool Mate during the Fabtech Atlanta. Equipped with an external automatic and intelligent tool changer, the E-Brake C 200T with Tool Mate offers great time savings when producing small series.

Automated solutions

The Tool Mate works very intuitively and does not require extensive training. The SafanDarley E-Control control takes care of the execution of the tool change. The correct tool setting is loaded and used directly on the machine with offline software. The high-precision changer ensures that the tools are placed in exactly the right position. Due to the intelligent software, only the necessary changes are made and tools from the previous tool setup are reused. This results in significantly shorter changeover times. The tool storage warehouse has a capacity of 32, 52 or 60 meters, which gives an enormous space for the tools.

E-Brake 35T Mini Cell

Especially for the automatic production of small complex products, SafanDarley has an E-Brake Mini Cell in its range, an E-Brake 35T equipped with the latest type of FANUC robot. The Mini Cell has a modular construction and can be modified as desired with all standard options, even at a later date. This makes the E-Brake Mini Cell fully configurable to customer requirements.

During Fabtech we will show a very complete Mini Cell, equipped with a discharge conveyor for the scratch-free discharge of products outside the cell. The Mini Cell is also equipped with a pallet managing system. This system ensures the automatic supply of an empty pallet for stacking products. As soon as the pallet is full it is automatically transported outside the cell and a new pallet is fed in.

E-Brake 130T Ultra

During FABTECH, SafanDarley will also present the high-end press brake, the E-Brake 130T Ultra. The Ultra series comes standard equipped with CNC crowning as well as a dual touch screen monitor to create a paperless environment. The E-Brake 130T Ultra on the FABTECH is equipped with the optional E-Bend L Blue angle measurement system to work even more accurately and efficiently. The system constantly monitors and corrects the position of the Y axis based on the current product angle. This guarantees a final product with the highest angle precision.

Fabtech Atlanta, November 8-10, Booth number B6741

To predict the future, You must invent it

In today’s labor market it has become difficult to find skilled labor and even harder to retain the skilled labor. The average age of our skilled labor force is increasing and not enough young talent is entering the field. The cure to these business challenges is often automation.

Automated Solutions such as the R-Brake and the Mini Cell and Tool Mate help Fabricators navigate these issues, increasing the hours available for your press brakes to produce without skilled labor available, providing parts to tight tolerances part after part and significantly reducing the waste produced.

Read more

news

The E-volution in sheet metal processing is moving increasingly towards an automatically and digitally controlled factory. SafanDarley will present the latest innovations in sheet metal working at EuroBLECH 2022, including the complete program of automated solutions.

The 2022 SafanDarley North America Business Partner Meetings were held at our North American headquarters in Waukesha, Wisconsin on May 16th and 17th. All Distributors for North America were in attendance.