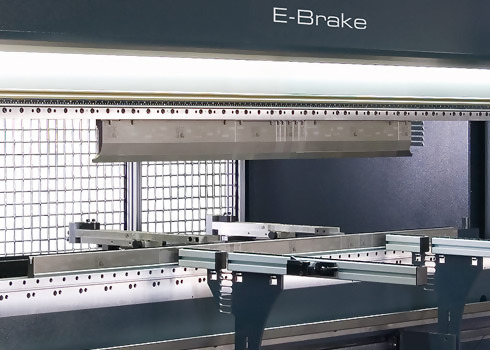

E-Brake 300T Ultra Dual Drive

Servo-electronic bending with an E for even bending

- Full electric drive

- More than 30% higher productivity

- Up to 50% energy saving, low CO2 emissions

- No harmful hydraulic oil

- Noiseless operation

- Full working length backgauge

- User friendly touch screen control

Integrated safety

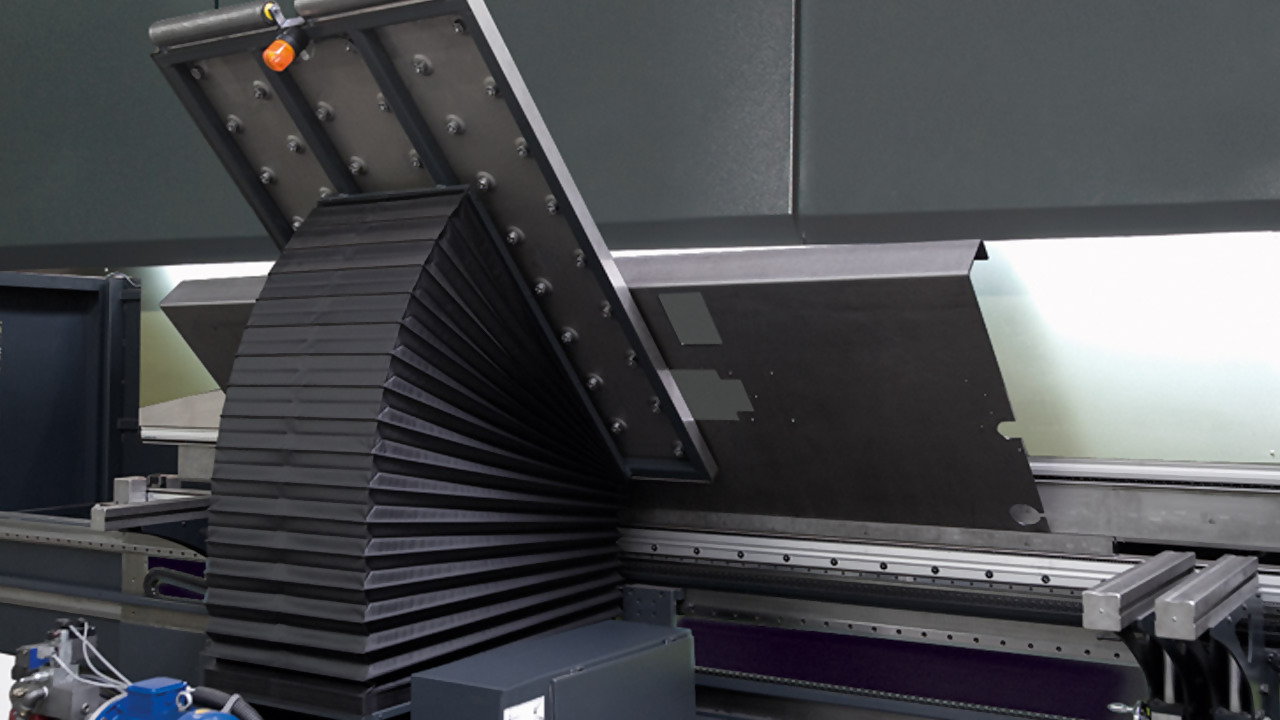

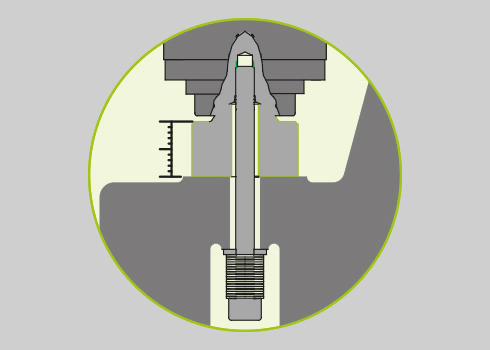

Work fast without risk: SafanDarley makes that a reality with the safety system integrated within the controls. It works with a safety light screen that is automatically directed from the SafanDarley E-Controls. In addition, the SafanDarley E-Brake has an additional in-built safety provision. The application of a spring return means that the top beam will always move upwards in the event of a failure.

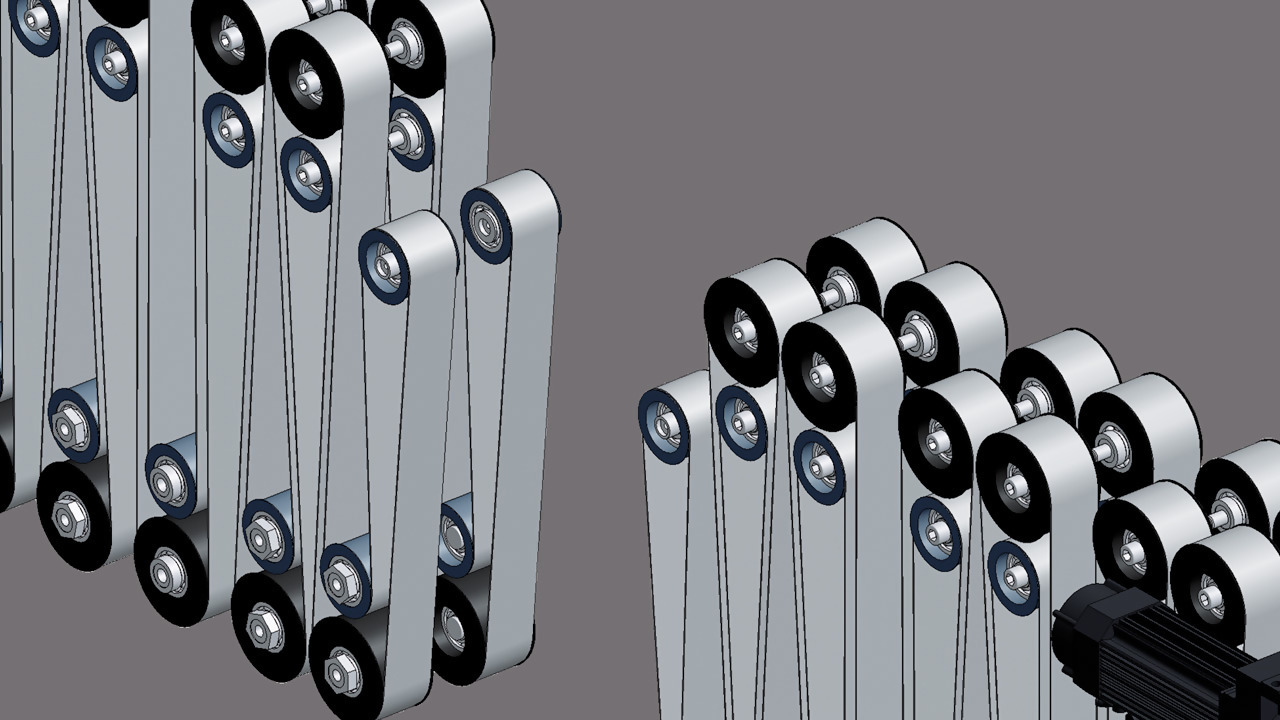

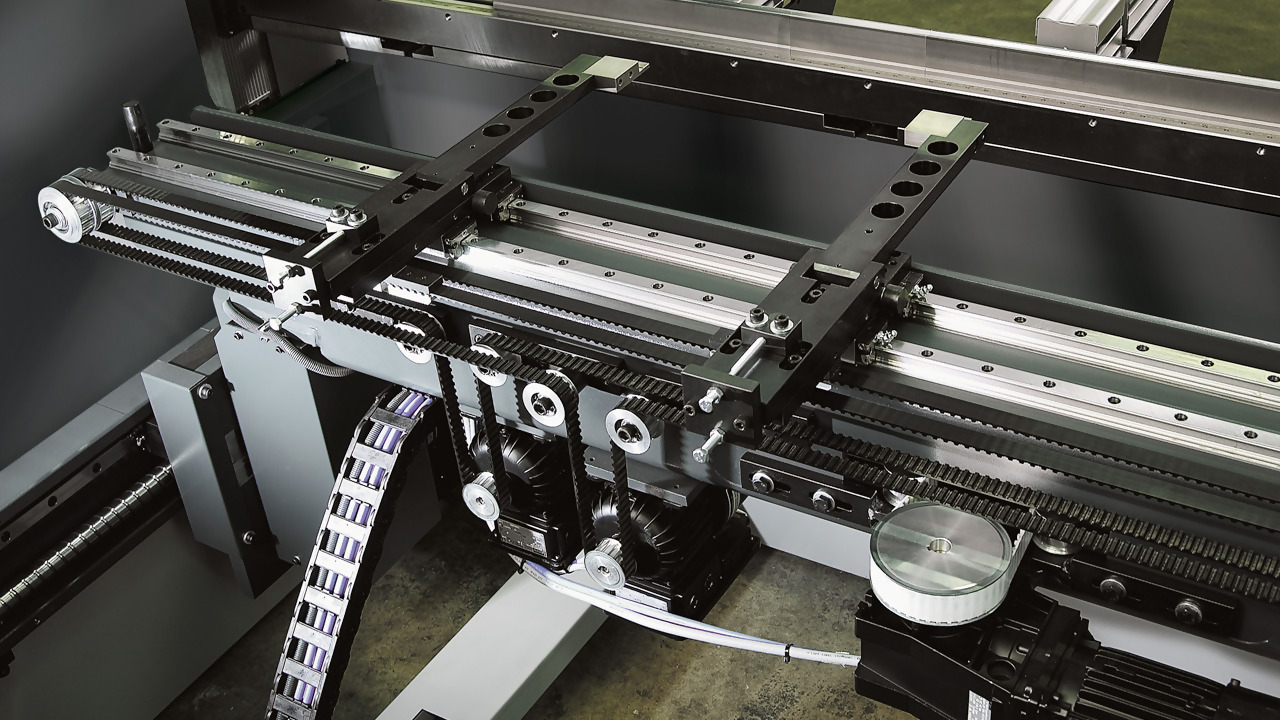

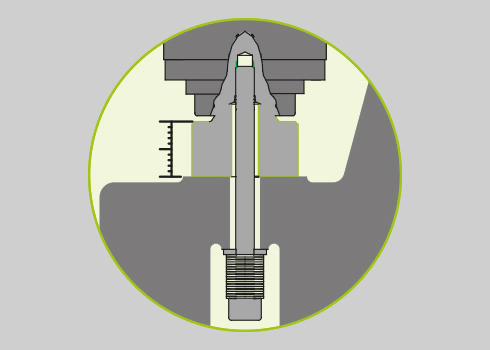

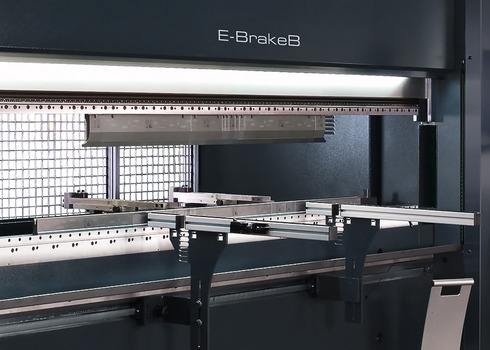

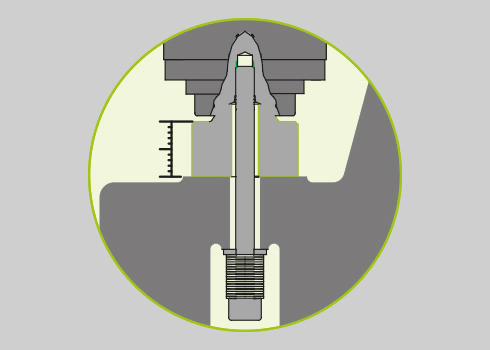

DualDrive System

The SafanDarley E-Brake 'Dual Drive' 300T brings the unique advantages of the E-Brake technology to the higher tonnage segment of the market with pressing forces of up to 300 tons. This is possible due to the unique and patented 'Dual Drive' drive with a double pulley system.

Servo motors drive the press beam via the double pulley system. A balanced interplay between fixed and flexible rollers and flexible belts ensures an even distribution of forces over the entire press beam. Even with 300 tons of pressing force the deflection of the beam is minimal.

Request a demonstration

Thank you

Thank you for your request

Technical specifications

| Model | Tonnage | BowLength | Pressure force in US Ton | Maximum stroke in inches | Q-dimension in inches | Closing speed in inch/min | Bending speed max. in inch/min | Return speed in inch/min | Motor power in kW | Weight in lb |

|---|---|---|---|---|---|---|---|---|---|---|

| 300-4100 | 300 | 160 | 330 | 16 | 27 | 213 | 48 | 213 | 30 | 48.502 |

Standard features

- SafanDarley EC20 Touch Screen CNC press brake controls

- CNC-controlled R- axis

- CNC-controlled Y1-Y2 axis (top beam adjustable inclined +/- 0.1 inch)

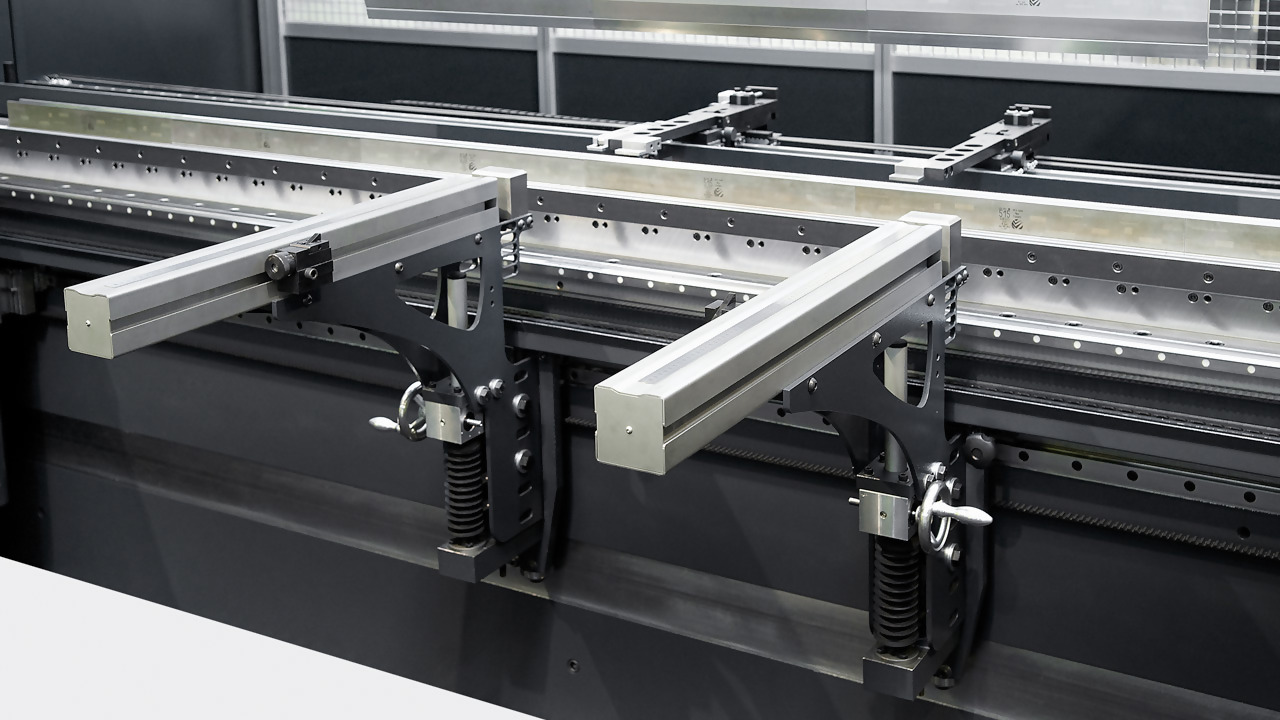

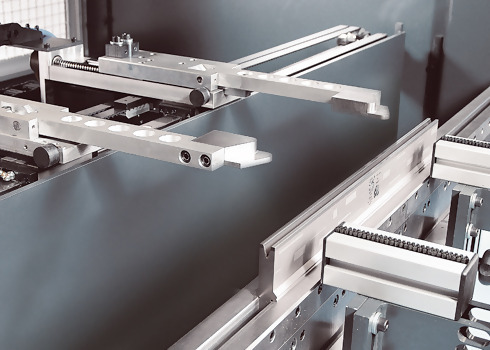

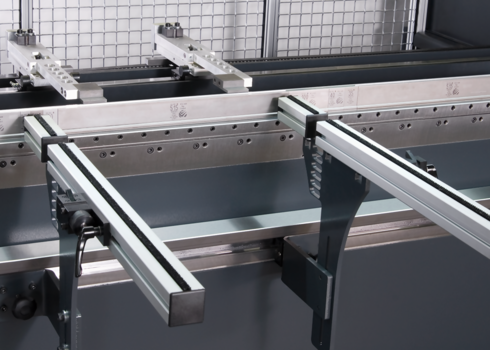

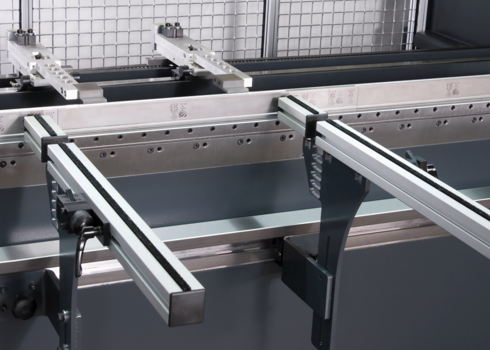

- CNC-controlled back gauge (X-axis) with a wide range

- Manual adjustment of 2 back gauge fingers across a linear parallel guide

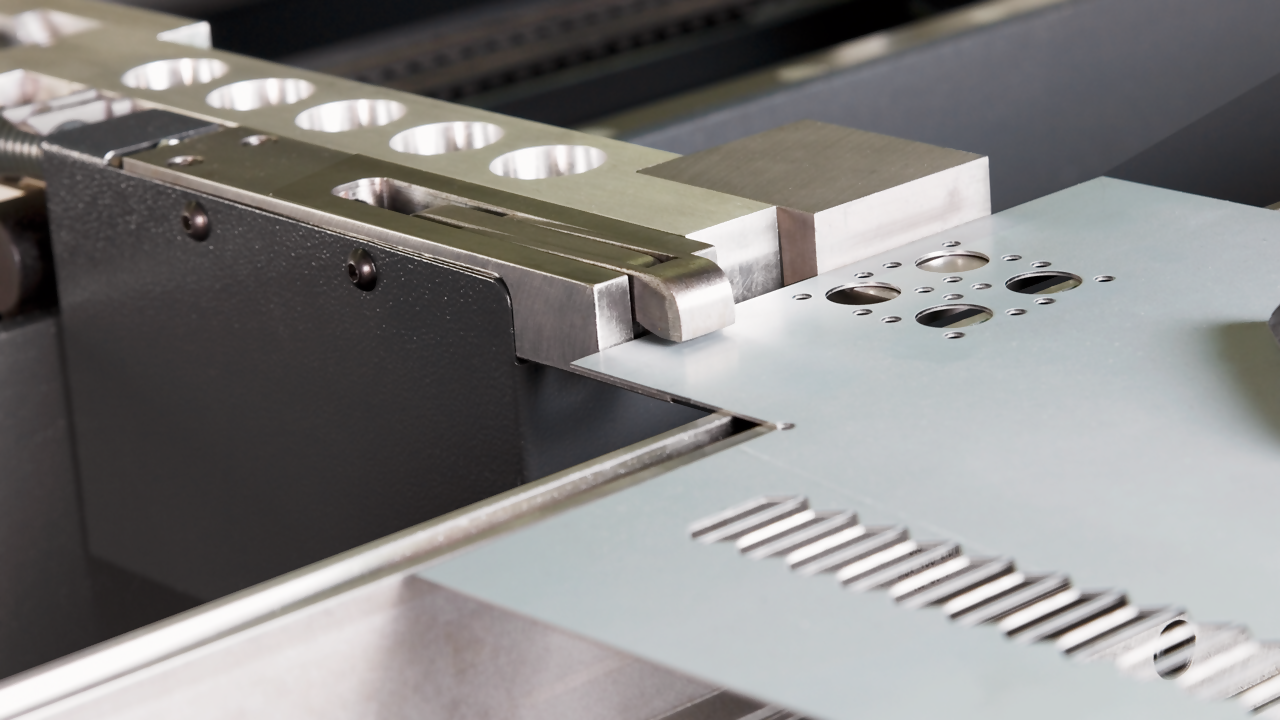

- NSCL II MC Premium top tool mechanical clamping system and NSCR II MC Premium crowning

- Daylight of 27.16 inch (Q-dimension)

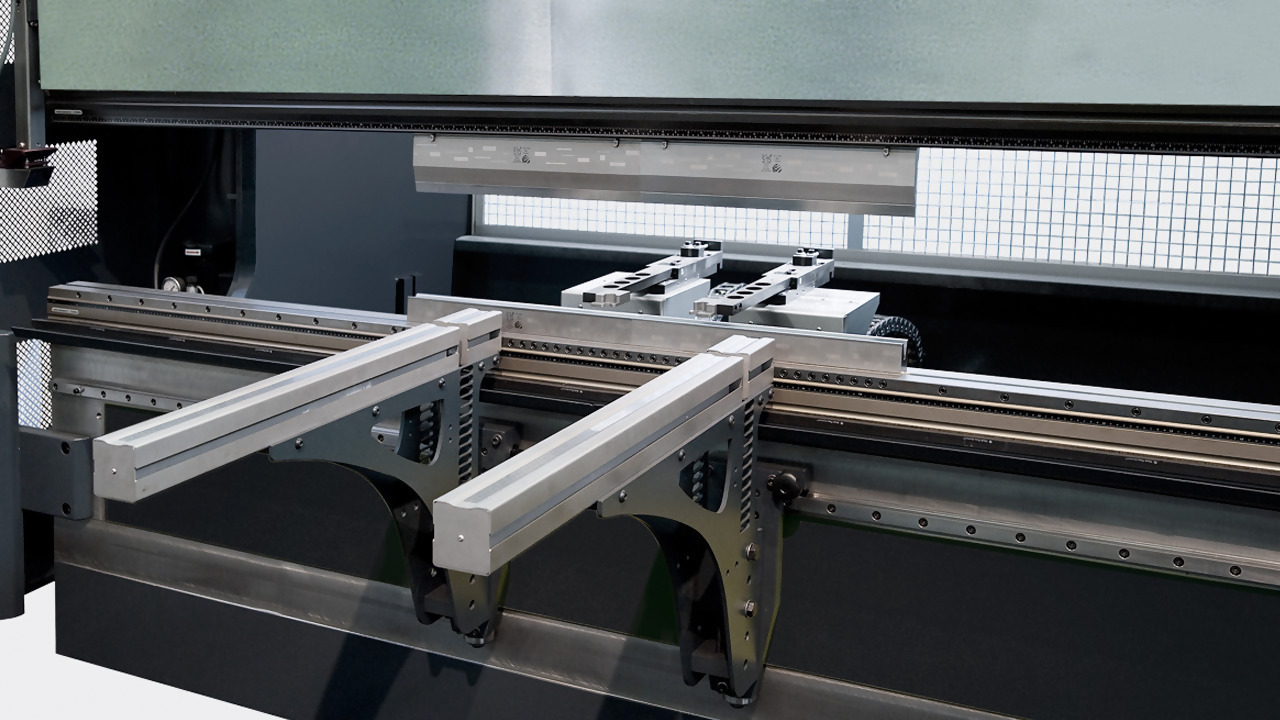

- 2 support arms (11.81 inch in length)*

- 1 Hold to Run operating console

- Programmable and integrated safety light guard*

- Safety in conformance with CE*

Available accessories

« Back to the overview

Options:

- I-Mate: maximum plate weight 100kg

- E-Mate 2000: maximum plate weight 500 kg*

* available for Ultra version

Options:

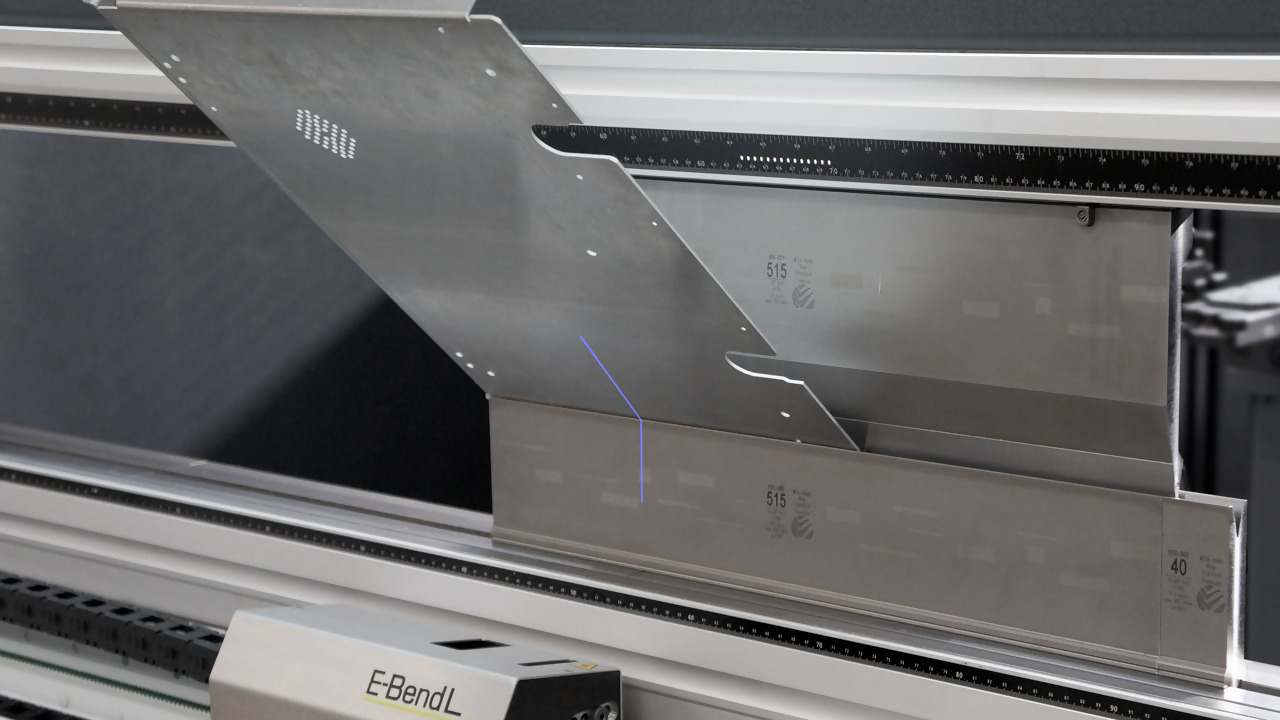

- E-bend S: sheet thickness measuring system

- E-bend L Blue: angle measuring system*

*available for Ultra version

Options:

- Movable support arms

- Moveable support arms, height manual adjustable

- Moveable support arms, height pneumatically adjustable

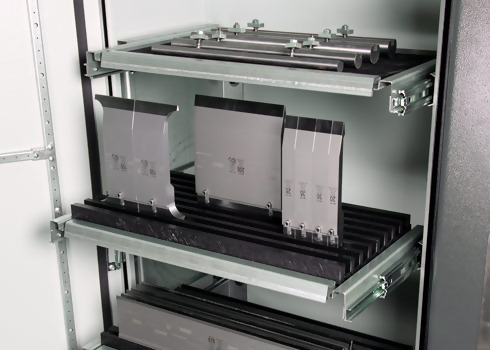

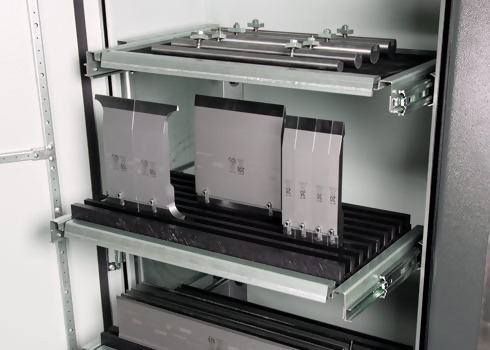

Options:

- New Standard

- European Style

Extra option:

- Smart Tool Locator

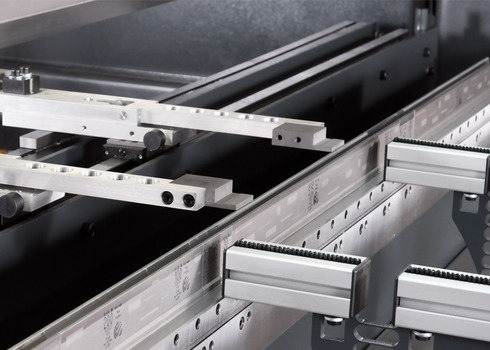

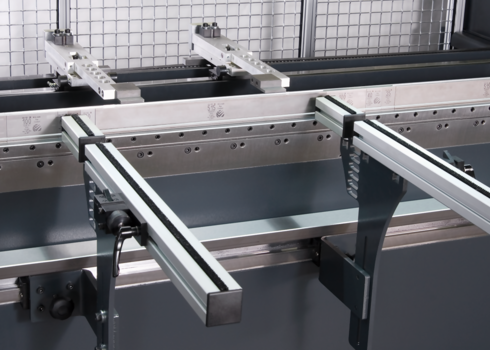

Options:

- CNC-Controlled Z1+Z2 axis

- CNC-Controlled Delta X axis

- CNC-Controlled 3D back gauge*

*available for Ultra version

Options:

- 25.6 inch (650mm)

- 27.5 inch (690mm)

For 300T only:

- 29.5 inch (750 mm)

- 31.1 inch (790mm)

Options:

- EC20*

- EC3D

- Dual landscape screen

*standard for E-Brake Ultra and H-iBrake

- Materials cupboard on the machine

- depth adjustment of the back gauge fingers (X1+X2)

- height adjustment of the back gauge fingers (R1+R2)

- width adjustment of the back gauge fingers (Z1+Z2)

The E-Mate 2000 has a lifting capacity of 2000Nm with a plate weight of 440Lbs (200kg) and is movable on a lineair rail and can easily be removed by a linge operator.

I-Mate provides automatically calculated support during the entire bending sequence, from flat sheet to the programmed bending angle based on material type, sheet thickness and lower tool parameters.

I-Mate has a lifting moment of 750 Nm with a maximum sheet weight of 220Lbs (100 kg).

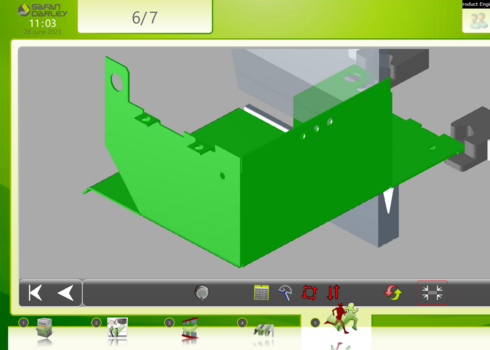

Complete Touch Screen convenience

The SafanDarley E-Control is fully touch screen, whereby the only buttons visible on the 21” screen are those that are needed during operation. The controls simply run on a PC under Microsoft Windows®, the software was developed based on Microsoft.net Framework.