Automated Solutions Cell-Control

Software platform: ASC-Control

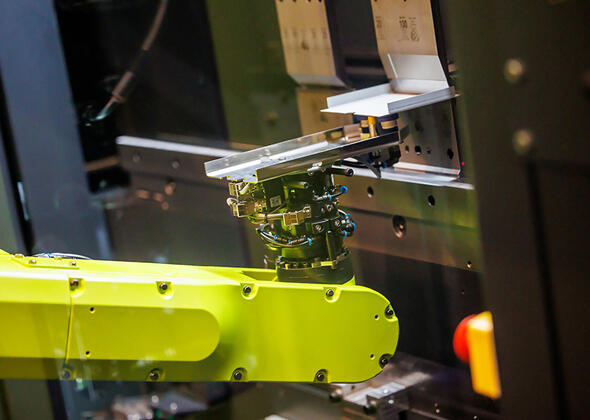

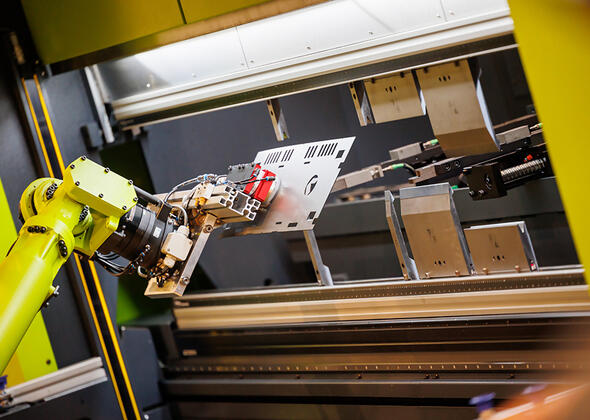

Automated Solutions Cell-Control is SafanDarley’s software platform for the automated cell. ASC-Control is a very user-friendly and flexible management platform that was born out of the need to allow even employees with little experience to operate automated machines. Fully developed and supported by our in-house software team. The modular structure of the software makes it easy to implement customer-specific requirements and adapt the layout of the cell.

Different operating levels

- Product engineer: access to all options

- Expert operator: customisation of programmes

- Operator: secure access to existing programmes

Without operator intervention, several products can be queued by the product engineer and then processed one by one by the operator.

It is also possible to abort an order and prioritise a higher-priority order and then return to the first product to complete the job even from the middle of the stack.

SafanDarley ASC-Control

- SafanDarley look and feel

- E2P: Easy to program

- User friendly interface HMI

- Different user levels

- Main overhead control

- Central point for Alarm messages

- OPC UA supported (Open Platform Communications Unified Architecture)

- Remote access for customer

- Production flow control

- Modular build / open architecture

- Flexible set-up, modification on customer level

Simple operation,

optimal ease of use

If the automated cell is equipped with automatic gripper and tool change, ASC-Control offers the possibility of automatically loading the new programmes into the robot and press brake, the tool setup and another gripper into the machine between two jobs.

In “expert mode”, it is even possible to easily add new tools or grippers yourself. This flexibility provides unlimited storage of tools and grippers so that the cell can be rearranged for each day or week depending on production.

The ASC control constantly communicates with the robot and press brake to monitor the status of the entire cell. The error messages and notifications of the respective cell component are immediately and clearly displayed on the screen. Thus, the ASC-Control tracks every item in the cell and knows exactly where it is located. Attached is an example of tool tracking. If the tool is in the gripper, it is no longer visible in the warehouse and will only be visible in the press brake in the next step.

ASC-Control Gateway

ASC-Control Gateway is a collective name that can open up communication options to various systems. The gateway is equipped with the following standardised protocols: OPC-UA and API preparation. This makes it easy to implement the cell in your production environment. For example, communication protocols have already been set up to work together with AGVs, automated warehouses and complete punching lines. Through the gateway, it is easy to receive status and error messages on your office network. If your production process communicates in other ways than mentioned above, we are interested in adding another protocol to the gateway, if technically possible.

Remote access and service

Remote access provides the ability to prepare the production order for the cell so that the operator only has to select the correct list. With the remote service support function, SafanDarley Service can log in to your ASC-Control to provide easy remote support.

Request a demonstration

Thank you

Thank you for your request