FABTECH Chicago

FABTECH 2019

The E-volution in sheet metal working continues to progress towards a factory that is fully controlled and managed digitally. At FABTECH 2019, SafanDarley will present the latest innovations in sheet metal working, with a focus on Automation.

Automated Bending Solutions

SafanDarley will focus this FABTECH on automation. In addition to stand-alone machines, such as Electronic and Hybrid press brakes, SafanDarley will present the automatic bending systems, the R-Brake and the E-Brake Mini Cell.

R-Brake 130T

The SafanDarley R-Brake is a revolutionary bending cell concept based on the SafanDarley E-Brake Ultra press brake. In the SafanDarley R-Brake, the press brake and robot are integrated into one system. In addition to advantages, such as a completely clear floor area in front of the machine, the R-Brake can be equipped with an automated tool and gripper changing system. This also makes the R-Brake suitable for smaller batch sizes. It’s also possible to switch quick and easy to manual bending.

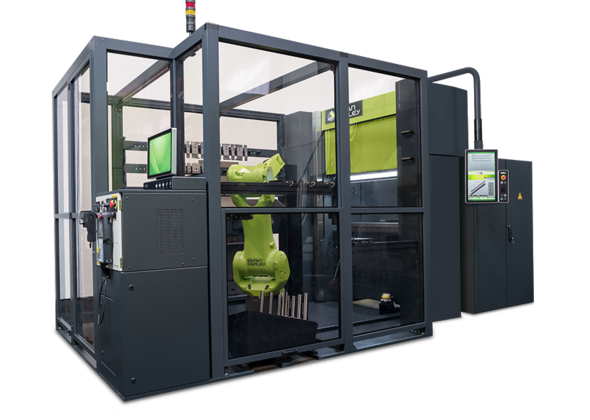

E-Brake 35T Mini Cell

The second automation solution on offer is the E-Brake 35T Mini Cell. This system is characterized by its compactness, making it ideal for bending smaller sized parts. The optional automatic tool and gripper change function makes it possible to quickly switch between different products.

Back to the overview

H-Brake Hybrid 110T-1600

The third machine SafanDarley will present is the H-Brake Hybrid 110T Premium. This compact machine is specially designed to achieve higher tonnages on a short working length. The base is a O-frame technology from the E-Brake range, ensuring a stable structure with minimal deflection. It is powered by energy-efficient hybrid technology, creating a compact press brake with a very high tonnage density.

E-Brake 40T Premium Ergo with large Q-dimension

We will also present an E-Brake 40T Ergonomic with an extremely large Q-dimension. As standard, the E-Brake 40T is equipped with a Q-size of 590 mm, the machine we will show on the FABTECH booth has Q-size of 1090 mm. The enlarged Q size gives the ability to bend products with high upright sides.

Offline bending software

On the SafanDarley booth, we will be providing AutoPOL software demonstrations. Smart bending with the innovative AutoPOL 3D-offline programming software guarantees complete and reliable process control. From 3D design to production in just a few steps. The additional Batch & Remote functionality enables automatic processing of multiple parts. All tasks are performed without user input, results are reported back and production data created. It dramatically reduces programming costs and reports the overall outcome for each step in the process.

Get in touch with SafanDarley

Thank you

Thank you for your request

Read more

news

As part of the commitment to the US market and following the successful growth in the Midwest and south east, SafanDarley North America, LLC will be relocating its US facility to Waukesha, Wisconsin.

SafanDarley recently commissioned an H-Brake 800T at Bässler in Olpe (DE). The H-Brake 800T with a working length of 8200 mm has a weight of approximately 95.000 kg. For transport