To predict the future

Struggling with Labor Shortages and Rising Costs? Automation is the Answer.

Finding and keeping skilled operators is tougher than ever. Experienced workers are retiring, fewer young talents are entering the field, and material costs keep going up. On top of that, inexperience leads to higher waste—waste that’s more expensive than ever.

SafanDarley’s Automated Solutions – including the E-Brake 35T Mini Cell, Multi Cell, R-Brake, Robo Mate, and Tool Mate – help you:

- Produce more hours without relying on skilled labor

- Maintain consistent, high-precision quality

- Reduce material waste and cut costs

See it in action?

Request a free Automation consultation today and discover how automated bending can transform your production.

Fill in the form below and one of our application engineers will get in touch to schedule your personal demo.

Request for a free

Automated consultation

E-Brake 35T Mini Cell

This 100% electric Mini Cell is characterised by its compactness, making it ideal for bending smaller sized parts. The optional automatic tool and gripper change function makes it possible to quickly switch between different products.

The E-Brake Mini Cell is equipped with a FANUC robot with a handling weight of 20 kg, a supply station for four product stacks, a delivery station and a discharge chute.

Multi Cell

The SafanDarley Multi Cell is a versatile addition to the automated bending solutions for all midsized products up til 500x2000 mm product size and 40 to 125 Ton pressing force. This innovative automation solution allows for the bending of a wide variety of products in a very compact space.

When the market starts demanding more flexible robotized bending solutions, there is need for a change of perspective. SafanDarley has developed the ultimate solution for the mid-sized sheet metal product range by making a cell that fits every demand. This retrofit-capable system ensures that your Multi Cell stays cutting-edge, with the ability to install new technology and features as they become available, safeguarding your investment for the long term.

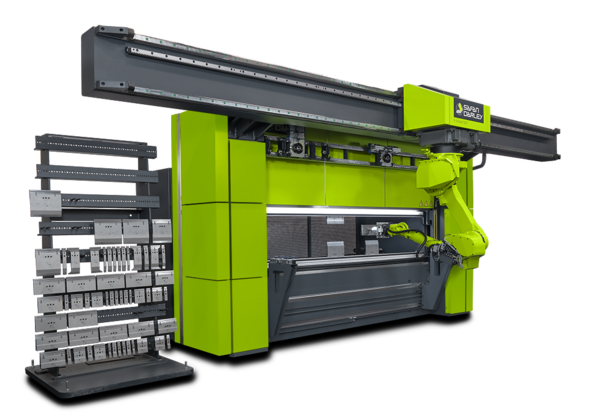

R-Brake 130T

With the R-Brake, the press brake and the robot are integrated into one system. One of the advantages of the new R-Brake is a fully automated tool and gripper change that is connected to the machine. Together with the product, they can be programmed completely offline using SafanDarley’s RoboBend offline simulation software.

The robotic arm moves horizontally along a 6-metre long traverse at the top of the press brake. This makes it also possible to bend manually.

Robo Mate

The revolutionary SafanDarley Robo Mate is meticulously designed to take your automated bending cell to the next level. By utilizing only 2 or 3 support positions for the rail, there will be floor space left for other cell components or product stacking.

Robo Mate is designed to be paired with a SafanDarley press brake (E-Brake, hydraulic, or hybrid) to give the option of switching to automated production at any time. This guarantees the most efficient use of your entire workspace. Discover unmatched flexibility and efficiency, all while keeping your footprint to a minimum. Meet the future of automated bending with the SafanDarley Robo Mate.

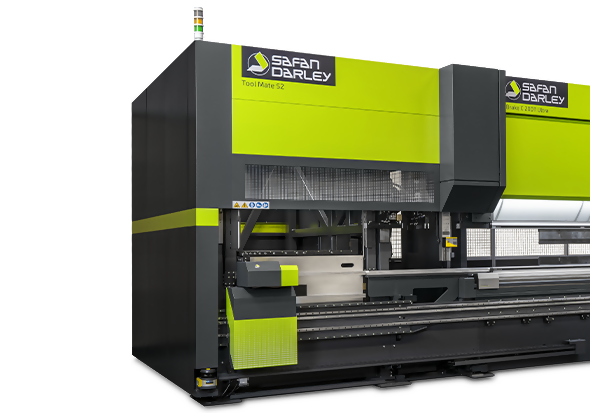

Tool Mate

Safandarley's Tool Mate is one of the largest CNC-controlled tool storage systems for press brakes on the market with the most usage flexibility. The perfect solution for working with high-mix, low-volume orders with complex tool set-ups in today's modern production environment. So you work even more efficiently and increase productivity.

The tool storage magazine is positioned to the left of the press brake and has a capacity of 32, 52 or 60 metres, which gives extensive storage for a variety of Upper and Lower tools.

The shuttle collects the tools from Tool-Mate, after which they are placed in the correct position on the machine. The tool rotation station allows the top tools to be rotated 180 degrees, enabling tools to be used both ways thus eliminating the need for a double tool set.