Smart Production

More efficient, flexible and smart

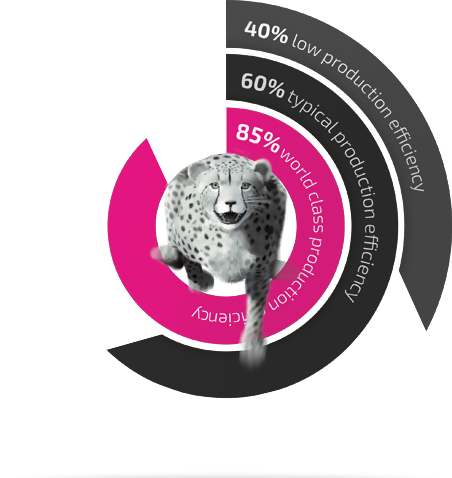

With new technology, SafanDarley paves the way to smarter manufacturing in the Smart Industry. Smart Industry is a method that gives the manufacturing industry more clout by maximizing the use of the latest information and technological developments. This can be achieved by thorough digitization and linking of devices, production resources and organizations, thus creating a new, integrated method of manufacturing. With SafanDarley, this means more efficient and more flexible manufacturing of high-quality and tailor-made solutions. In concrete terms, “smart manufacturing” means improved OEE, i.e. Overall Equipment Effectiveness.…

Call me back for personal advice

Thank you

Thank you for your request

30% increased efficiency

30% increased efficiency and more output... Do the math and realize what this will mean for your company. SafanDarley will be happy to help you realize such savings.

Offline software

- The correct sheet pattern based on material and tools

- Feasibility tested through simulation

- The correct tools set up in the equipment

- Immediate manufacturing

Machine control

Machine control can also contribute to more efficient work. Your efficiency will be increased by a number of standard options the software has to offer.

Batch production

- In the controller you can predefine the various products that require bending so that you will not unnecessarily lose time in between batches.

EC40 smart

- 3D programming on a tablet

- Programming at any location

- No production interruptions

Database for bending

- Get it right the first time: even the first bending will be correct, due to the fact that factors which may affect the material are stored in the database.

Double display

- Ensures additional information in a paperless environment.

Tool changing / Tool systems

A lot of time is lost searching for the right tools and ensuring the right positioning in the machine. In order to set this up more efficiently, you can use the following features:

Tools

- A fixed set of tools at each machine prevents delay.

- The use of quick tool change (New Standard)

- Hydraulic clamping accelerates the changing process

Smart Tool Locator

- The smart Tool Locator indicates where the tools are supposed to be, thus speeding up the process and preventing mistakes.

Tool Identification and Positioning System (TIPS)

- With the TIPS option, manually placed tools are recognized as well and are placed back in the machine

Finally, good planning prevents tools from having to be changed unnecessarily often.

Measuring systems

E-Bend L Blue angle-measuring system

- SafanDarley's E-Bend L Blue angle-measuring system allows you to work even more precisely and efficiently. The system consists of two laser sensors, one at either side of the table, which are CNC-controlled. The system continuously monitors and corrects the position of the Y axis on the basis of the current product angle, thus guaranteeing an end product with the highest corner precision.

E-Bend S sheet thickness measurement

- This system performs sheet thickness measurements down to one hundredth of a millimeter. You can program exactly when measurements must be taken. Performing a measurement only takes one tenth of a second and the data is adjusted immediately in the control.