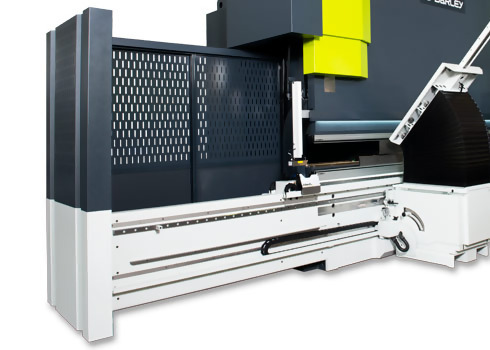

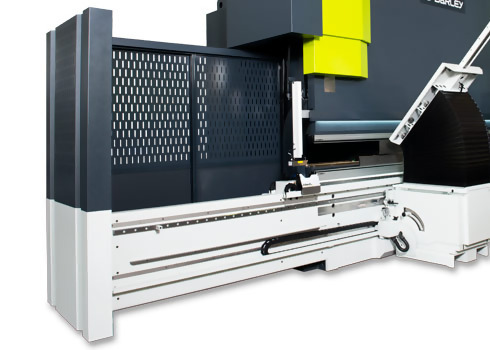

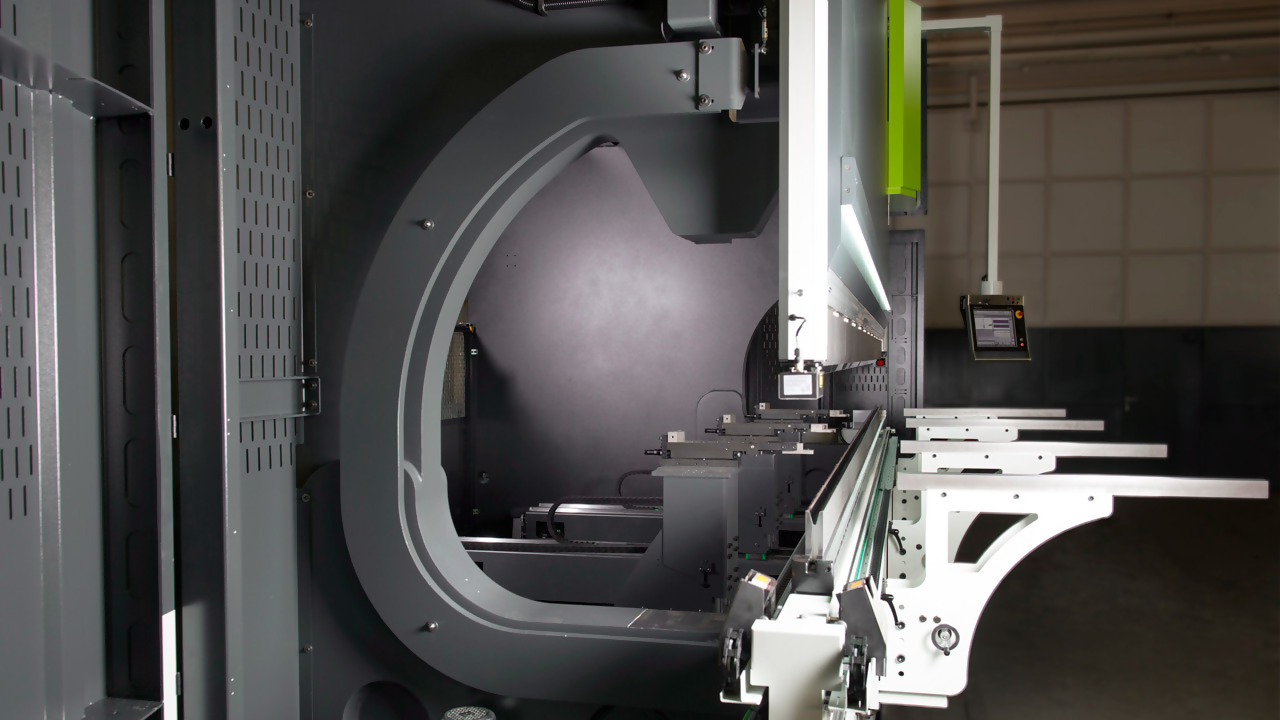

H-Brake HD 700-1000T

拥有最大效率的液压折弯机

配有HD选项的HD机器

- 带有Y轴重复精度(0.01mm)的高端折弯机

- 结实耐用的结构

- 快捷装置且周期时间短

- 具有两种不同控制类型的高水平自由状态

- 挠性缩口管和Q尺寸

- 定制方案

- 通用的弯曲辅助设备

- 各种不同吨位和长度

- 各种灵活的协同解决方案

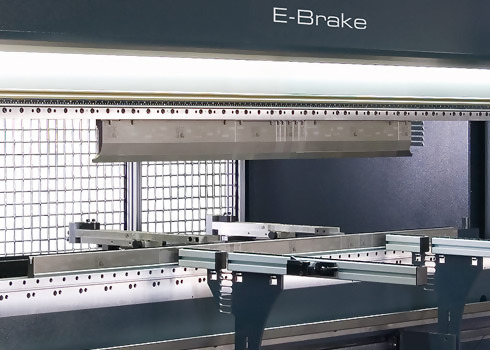

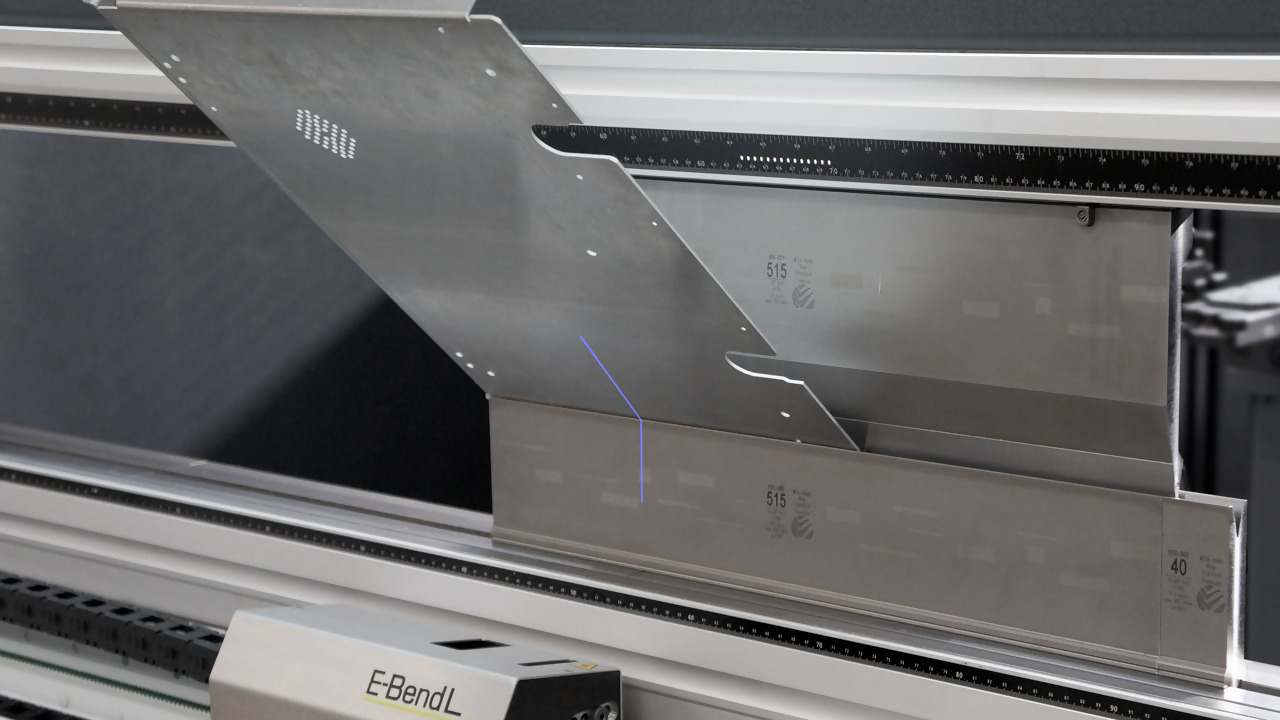

- 用E-bend L角度测量,首个弯度(小于0.5°)总是非常精确

整体安全性

工作速度快且无风险:SafanDarley将安全系统整合到控制设备中。安全系统配有一个安全灯屏幕,该屏幕受SafanDarley的E-Controls自动控制。

要求示範

Thank you

Thank you for your request

技术规格

| Model | 壓力噸位 | 長度 | 壓力(KN) | 剪切长度, mm | 最大行程 (mm) | 開口高度 (mm) | 下降速度 (mm/sec) | 折彎速度 (mm/sec) | 回升速度(mm/sec) | 馬達功率(KW) | 機床重量 (KG) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 500-4200 | 500 | 4200 | - | - | - | - | - | - | - | - | - |

| 500-5100 | 500 | 5100 | - | - | - | - | - | - | - | - | - |

| 500-6200 | 500 | 6200 | - | - | - | - | - | - | - | - | - |

| 600-4200 | 600 | 4200 | - | - | - | - | - | - | - | - | - |

| 600-5100 | 600 | 5100 | - | - | - | - | - | - | - | - | - |

| 600-6100 | 600 | 6100 | - | - | - | - | - | - | - | - | - |

| 600-8200 | 600 | 8200 | - | - | - | - | - | - | - | - | - |

| 800-4200 | 800 | 4200 | - | - | - | - | - | - | - | - | - |

| 800-5100 | 800 | 5100 | - | - | - | - | - | - | - | - | - |

| 800-6200 | 800 | 6200 | - | - | - | - | - | - | - | - | - |

| 800-8200 | 800 | 8200 | - | - | - | - | - | - | - | - | - |

| 1000-6200 | 1000 | 6200 | - | - | - | - | - | - | - | - | - |

| 1000-8200 | 1000 | 8200 | - | - | - | - | - | - | - | - | - |

| 1250-6200 | 1250 | 6200 | - | - | - | - | - | - | - | - | - |

Standard edition

- Delem DA 66T 2D or E-Control EC20 controls

- Controls mounted on a swivelling arm on the right side of the machine

- Y1/Y2 axis are CNC-powered

- X axis is CNC-powered

- R axis is CNC-powered

- Z1 and Z2 axis are controlled manually

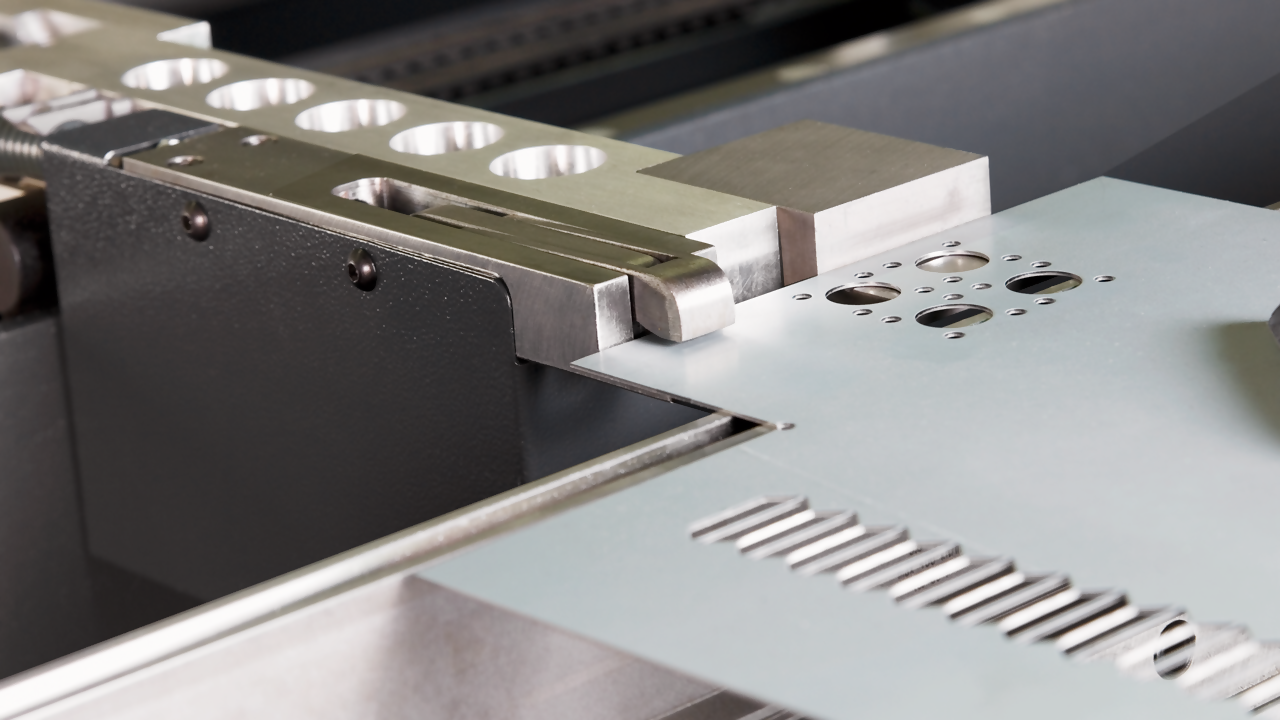

- Wila NSCL-II Premium top tool adaptor equipped with mechanical clamping,

- with a maximum load of 250T/mtr top-bearing and 300 T/mtr shoulder-bearing

- and CNC deep-hardened tool clamping

- Wila NSCR-II Premium CNC-powered crowning using mechanical clamping,

- CNC deep-hardened tool clamping, maximum load 300 T/mtr, Tx/Ty alignment

- 2 support arms (300mm)

- LazerSafe light beam protection, type LZS-004 (Delem)

- Programmable and integrated safety light screen (E-Control)

- Foot pedal including “Hold To Run”-function

- Work area lighting on the front and rear side of the machine

- Electronic installation of mains connection 3/N/PE 50 Hz 230/400 VAC

- Machine is designed in accordance with the prevailing CE standards

配件

« 回到導引

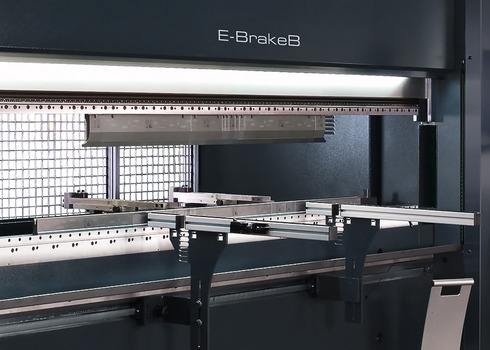

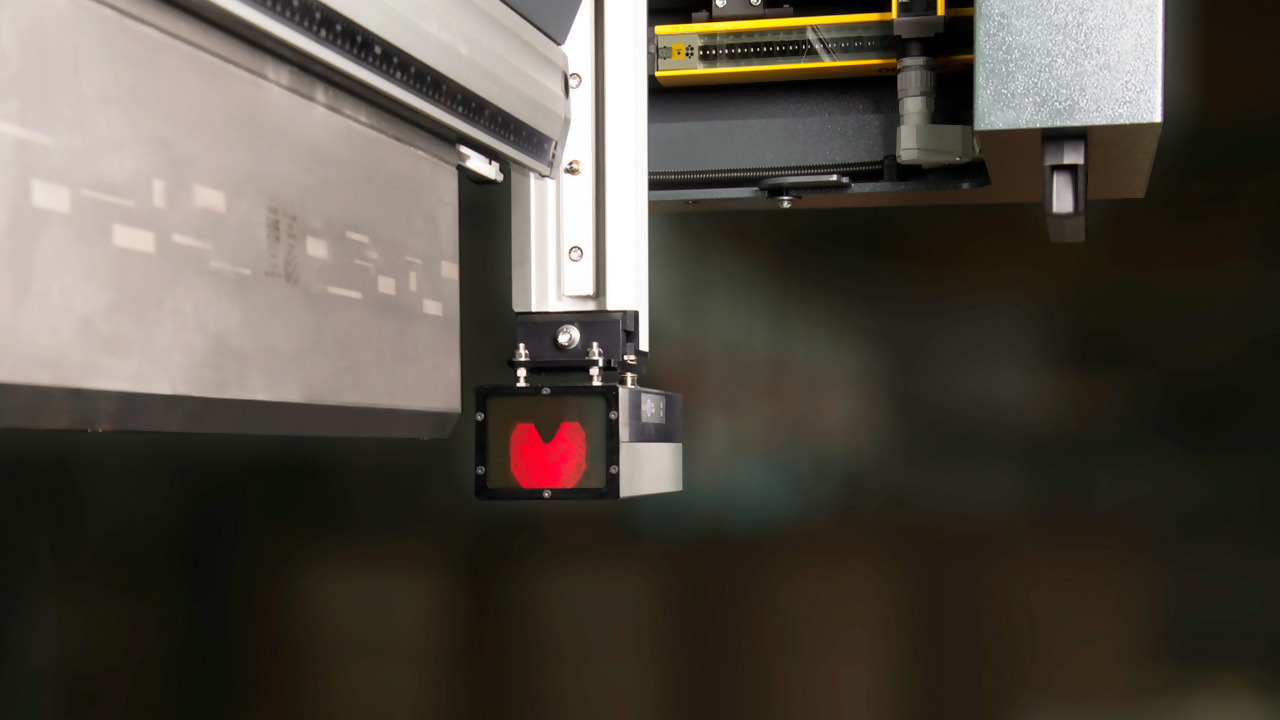

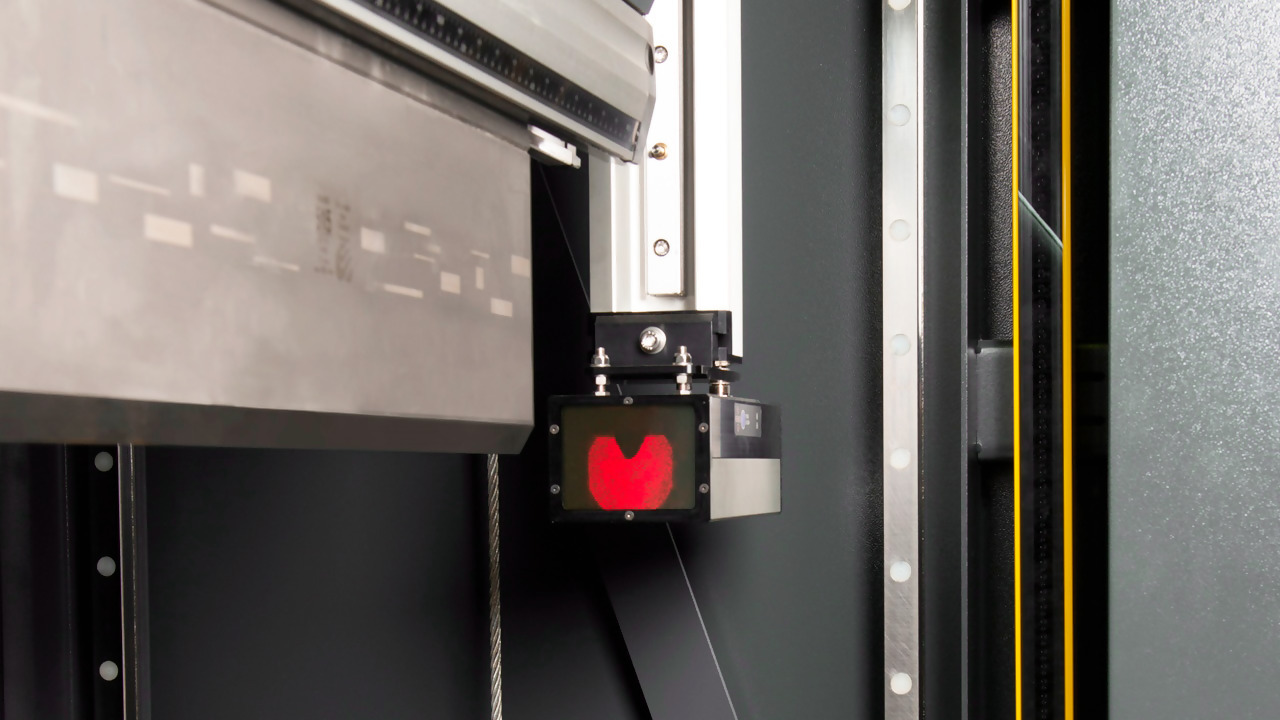

E-Bend L Blue

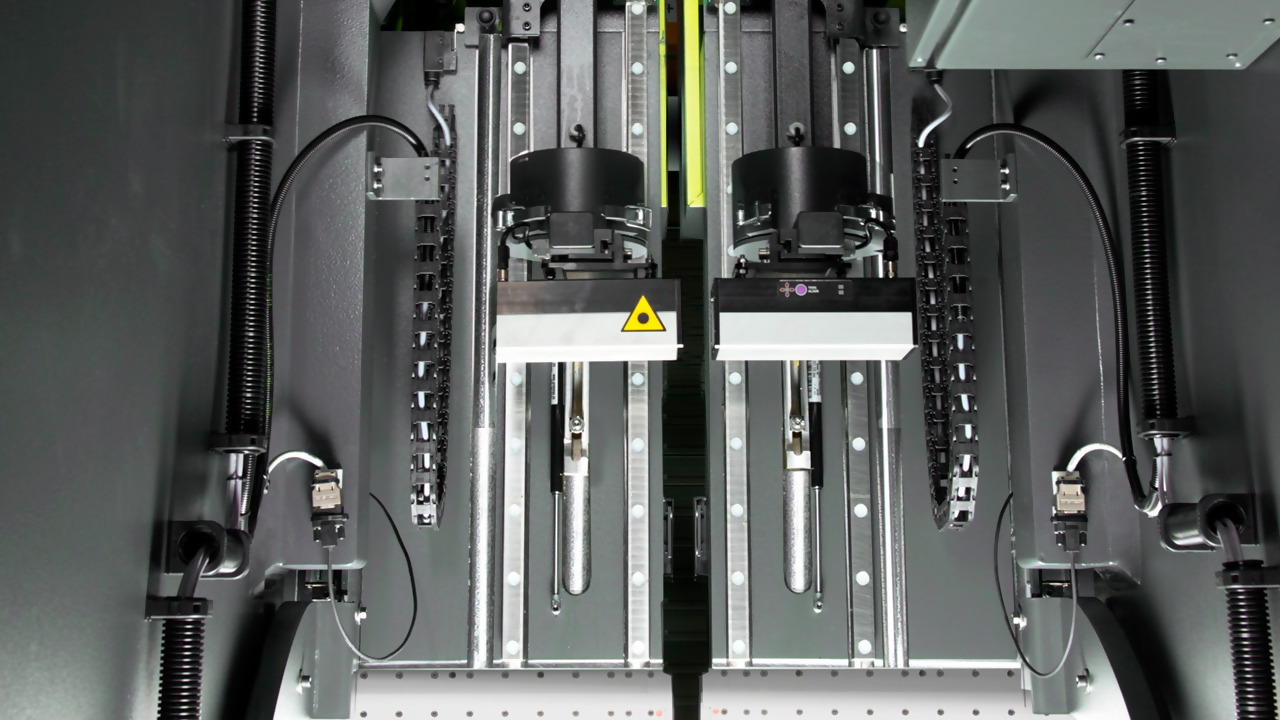

The system consists of two laser sensors on each side of the table, which are CNC controlled through the control system. The system continuously displays and corrects the position of the Y axis on the basis of the actual angle of the product, thus guaranteeing that the end product has the highest degree of corner precision.

Control

Options:

- EC20

- Dual display

- EC30

- EC40

- EC20

- Dual display

- EC30

- EC40

Bekijk opties

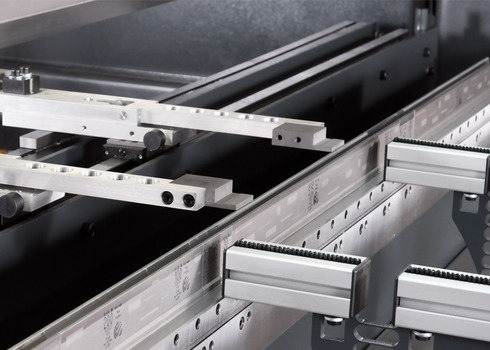

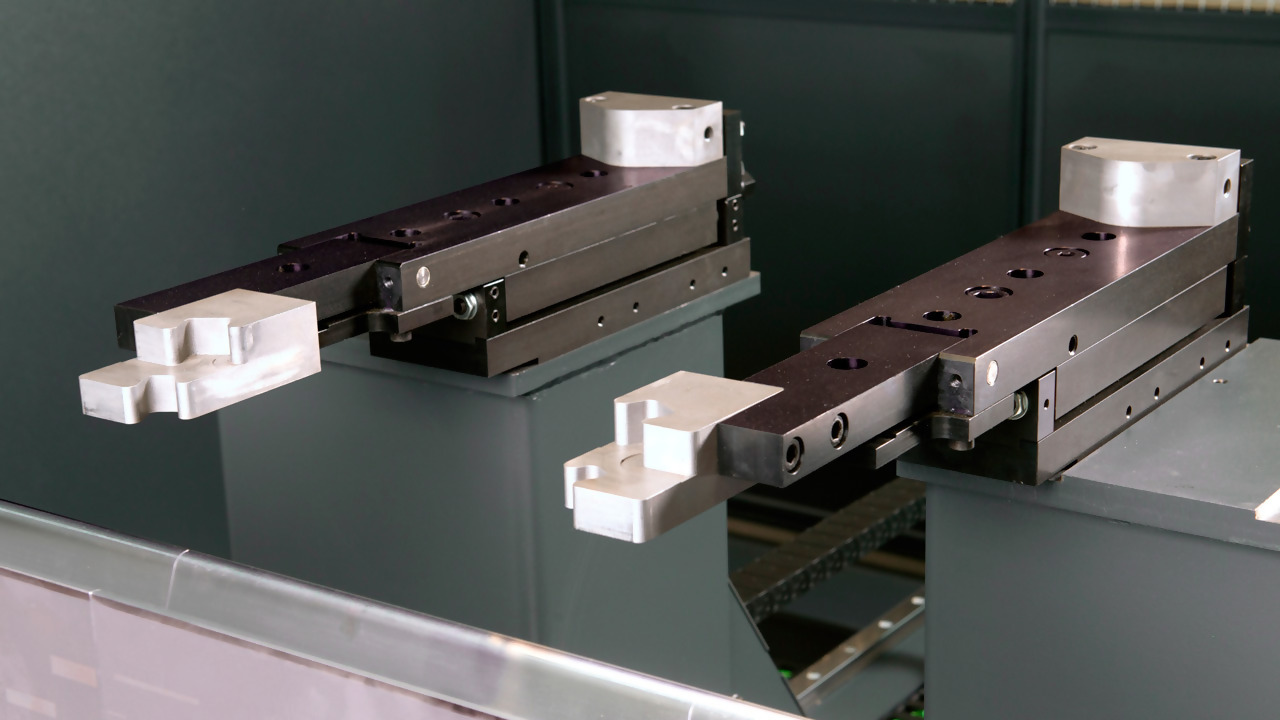

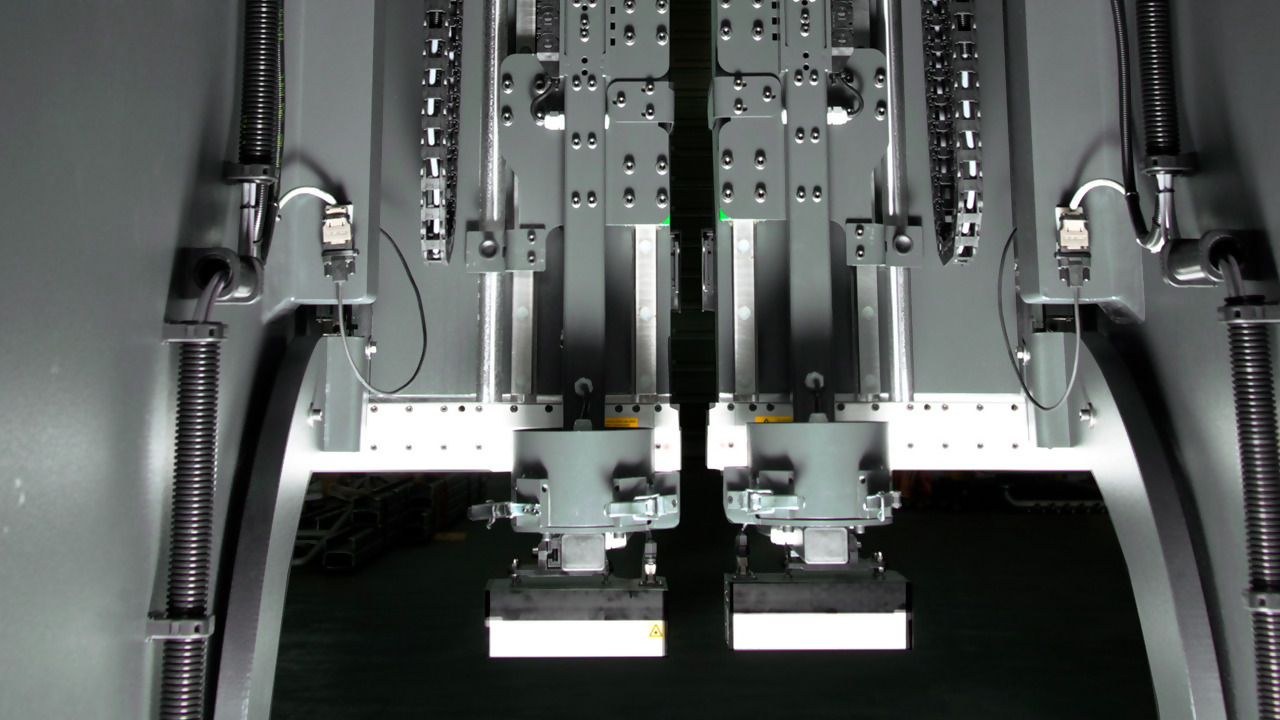

Axis / Back gauge system

Options:

- Z1+Z2 axis CNC controlled

- CNC controlled Delta X axis (horizontal transposition from a single back gauge finger)

- 3D back gauge

- Z1+Z2 axis CNC controlled

- CNC controlled Delta X axis (horizontal transposition from a single back gauge finger)

- 3D back gauge

Bekijk opties

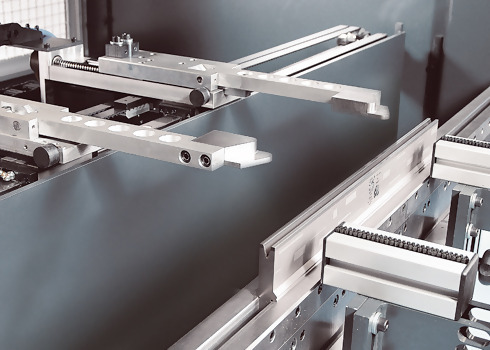

Support arms press brakes

Options:

- Fixed support arms

- Fixed arms can be moved along the machine

- Fixed arms can be moved along the machine, and the height can be adjusted with a hand wheel

- Fixed arms can be moved along the machine, and the height can be adjusted pneumatically

- Fixed support arms

- Fixed arms can be moved along the machine

- Fixed arms can be moved along the machine, and the height can be adjusted with a hand wheel

- Fixed arms can be moved along the machine, and the height can be adjusted pneumatically

Bekijk opties

Tool system

Options:

- New Standard NSCL-l HC pro hydraulic tool clamp system

- European Style clamping (only in combination with a Q size of 650 mm)

- New Standard NSCL-l HC pro hydraulic tool clamp system

- European Style clamping (only in combination with a Q size of 650 mm)

Bekijk opties

Measurement

Options:

- E-bend S

- E-bend L Blue

- E-bend S

- E-bend L Blue

Bekijk opties

Bending aid

Options:

- E-Mate maximum plate weight 30kg.

- E-Mate Plus maximum plate weight 150 kg.

- E-Mate 2000 maximum plate weight 500 kg.

- E-Mate maximum plate weight 30kg.

- E-Mate Plus maximum plate weight 150 kg.

- E-Mate 2000 maximum plate weight 500 kg.

Bekijk opties

Parking station

Options:

- Parking station on the left of the machine.

- Parking station on the right of the machine.

- Parking station on the left of the machine.

- Parking station on the right of the machine.

Bekijk opties

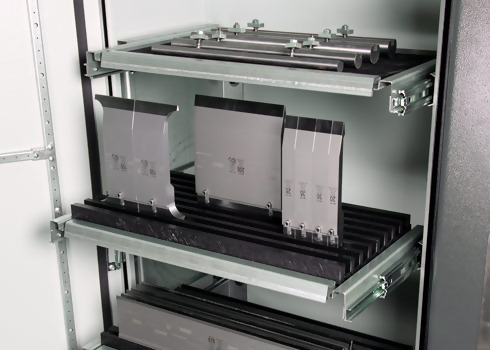

Materials cupboard

Options:

- Materials cupboard on the machine

- Materials cupboard on the machine

Bekijk opties

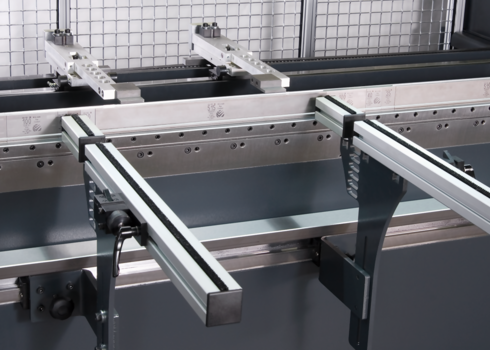

Axis Back gauge system 3D

Back gauge system that serves as a gauge for various plate material products Choice of back gauge systems depending on the complexity of the product to be bend.

Axis Back gauge system CNC controlled Delta X axis

Back gauge system that serves as a gauge for various plate material products Choice of back gauge systems depending on the complexity of the product to be bend.

Axis Back gauge system Z1+Z2 axis CNC controlled

Back gauge system that serves as a gauge for various plate material products Choice of back gauge systems depending on the complexity of the product to be bend.

Control EC30

The EC 30 control enables you to programme in 3D.

Control double display

By working with a double display, a paperless working environment is created.

E-Bend S

The system measures the plate thickness down to one hundredth. You can programme exactly when measurements must be taken.

E-Mate 2000

The bending aid supports and follows the plate very carefully throughout the entire bending process. The height and V size are variable and can easily be adjusted to the bending aid.

Fixed support arms can be moved

Fixed arms can be moved along the machine.

Fixed support arms moveable and adjustable in height

Fixed arms can be moved along the machine, and the height can be adjusted with a hand wheel.

Fixed support arms pneumatic

Fixed arms can be moved along the machine, and the height can be adjusted pneumatically.

I-Mate

This intelligent bending aid stands out for its user-friendliness, ergonomics and quality.

I-Mate provides automatically calculated support during the entire bending sequence, from flat sheet to the programmed bending angle based on material type, sheet thickness and lower tool parameters.

I-Mate has a lifting moment of 750 Nm with a maximum sheet weight of 22Lbs (100 kg).

I-Mate provides automatically calculated support during the entire bending sequence, from flat sheet to the programmed bending angle based on material type, sheet thickness and lower tool parameters.

I-Mate has a lifting moment of 750 Nm with a maximum sheet weight of 22Lbs (100 kg).

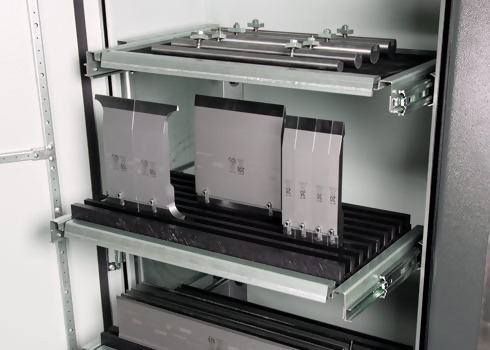

Materials cupboard

Materials cupboard on the machine. Storage facility for – for example – tools or documentation.

Parking station Left

Parking station on the left of the machine. Parking station for the benefit of bending aids and/or support arms. The bending aids and/or support arms can be placed on the left or right side on the outside of the machine.

Tool system European Style

European Style clamping (only in combination with a Q size of 650 mm). European Style tool intake.

Tool system New Standard

New Standard NSCL-l HC pro hydraulic tool clamp system. Quick exchange system for vertical loading and unloading through safety click in tools.

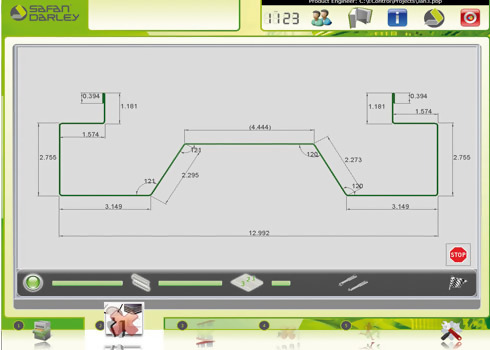

完满触屏带来的便利

SafanDarley E-Control是完全触屏,唯一在21” 屏幕可目视的按键是操作必需。控制系统在计算机以微软Windows®作平台,软体则以微软 net Framework作基础

重型后档规指针

1000 mm侧面机架间隙

光防护罩启动

光防护罩启动/关闭

汇接模式Lazersafe设施

单机模式Lazersafe设施

9轴式后档规

E Bend S

E-Bend L Blue

H-Brake 175-1250T movie