New software platform: ASC-Control

New software platform:

ASC-Control

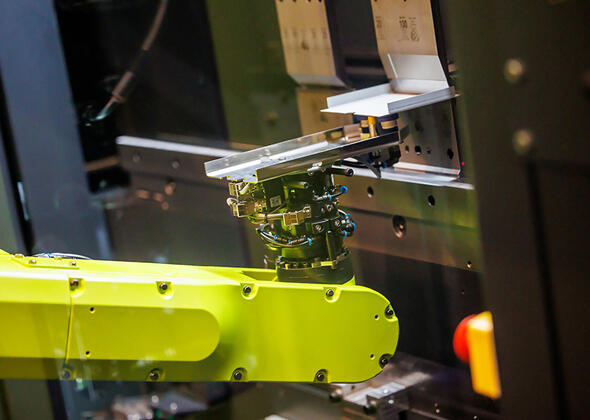

SafanDarley proudly presents the fully in-house developed software platform ASC-Control (Automated Solution Cell). This provides SafanDarley with a perfect software platform that enables all further developments with and around the electric E-Brakes and the hydraulic H-Brakes. Together with AutoPOL and RoboBend (offline software), ASC-control enables SafanDarley to offer a total package for all automated solutions. As a result, customers are no longer dependent on third parties and have only one point of contact for the entire package.

Powrót do przeglądu

High priority on ease of use

In developing the new software platform, high priority was given to ease of use. An extensive training programme is therefore not necessary for the operator. After sending a job to the ASC-Control, he can easily operate the machine and execute the job. This allows the operator to work efficiently and increases the productivity of the automated cell.

How this works was shown at the E-volution days 2023 using an E-Brake 35T Premium Mini Cell with palletiser and AGV. This is a cell for fully automated production of small complex products. It also allows successive bending of different products without intermediate programming. The cell is modularly built and can therefore be configured entirely according to the customer's wishes, thus achieving optimum efficiency and higher productivity.

Powrót do przeglądu

Basis for further development

"Now that ASC-Control is available, it provides a huge step forward in terms of ease of use, efficiency and productivity. And it lays a nice foundation for SafanDarley to develop on," says Gert Dekker (CE0).

In fact, only phase 1 of ASC-Control has been completed, the main outcome being that a customer can now run its robotic press brake cell independently. "In the next phases, we will go one step further each time," Dekker explains. "We are thinking about working with multiple robots in the cell, other brands of robots and various solutions for the supply and removal of materials and products".

Zobacz więcej

nowości

From 2023, all Mini Cell press brakes will be fitted with a double door on the infeed side as standard. This is SafanDarley's response to market needs. The redesign now makes it possible to run the Mini Cell for more than 8 hours without human intervention.

The relationship between Theuws Metaal and SafanDarley goes back a long way. "We have been a SafanDarley customer since 1999. So we have now been working closely together for over 24 years. In that period, we have experienced the best growth as a company, during which our machinery has also been modernised. We also offer specialised customised work. For this, we now have eight press brakes from SafanDarley, all nicely lined up. The press brakes help us enormously in responding to the various demands made on us by the market," Leo says.