Increased productivity through redesign of E-Brake Mini Cell

Increased productivity through redesign of E-Brake Mini Cell

From 2023, all Mini Cell press brakes will be fitted with a double door on the infeed side as standard. This is SafanDarley's response to market needs. The redesign now makes it possible to run the Mini Cell for more than 8 hours without human intervention. This modification significantly increases the Mini Cell's infeed capacity. The option of adding additional product tables including sliding door offers the possibility of doubling the infeed capacity.

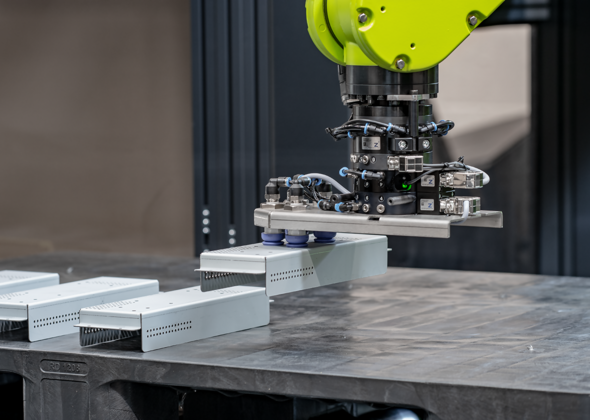

The basis of the Mini Cell is the E-Brake 35-1250 press brake and is characterised as a compact automatic flexible bending cell. The E-Brake Mini Cell is ideal for fully automatic production of small complex products and is fully configurable to customer requirements by adding a variety of options. The product tables in the Mini Cell are equipped with precision adapters as standard. These adapters guarantee a fixed position of the table including the products, making it possible to exchange several different product tables with each other. This makes the E-Brake Mini Cell unique in the market.

Scanners

In addition, it is now also possible to place environment scanners on the input side of the Mini Cell to detect whether the changing area is free. This option is needed when you want to start changing product/reference tables automatically. By adding this option to the Mini Cell, it is possible to change tables automatically with an AGV or other pick & place system so that the Mini Cell runs without an operator entering the cell.

Powrót do przegląduZobacz więcej

nowości

The relationship between Theuws Metaal and SafanDarley goes back a long way. "We have been a SafanDarley customer since 1999. So we have now been working closely together for over 24 years. In that period, we have experienced the best growth as a company, during which our machinery has also been modernised. We also offer specialised customised work. For this, we now have eight press brakes from SafanDarley, all nicely lined up. The press brakes help us enormously in responding to the various demands made on us by the market," Leo says.

Tosec is a Zwolle-based metal company that specialises entirely in sheet metal working. The company performs all operations at one location: cutting, machining, bending and welding. "Often we don't know today what we are going to make next month. That's why SafanDarley's new H-Brake 320T Ultra suits us perfectly. The custom-made press brake is widely applicable."